Process for reducing residual stress of butt-welding seam of dissimilar metal thick-wall barrel body

A dissimilar metal and butt weld technology, which is applied in the technical field of reducing the residual stress of the butt weld of dissimilar metal thick-walled cylinders, can solve the problems of high residual tensile stress level and complex residual stress distribution of dissimilar metal welded joints, etc., to achieve The effect of reducing the residual tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

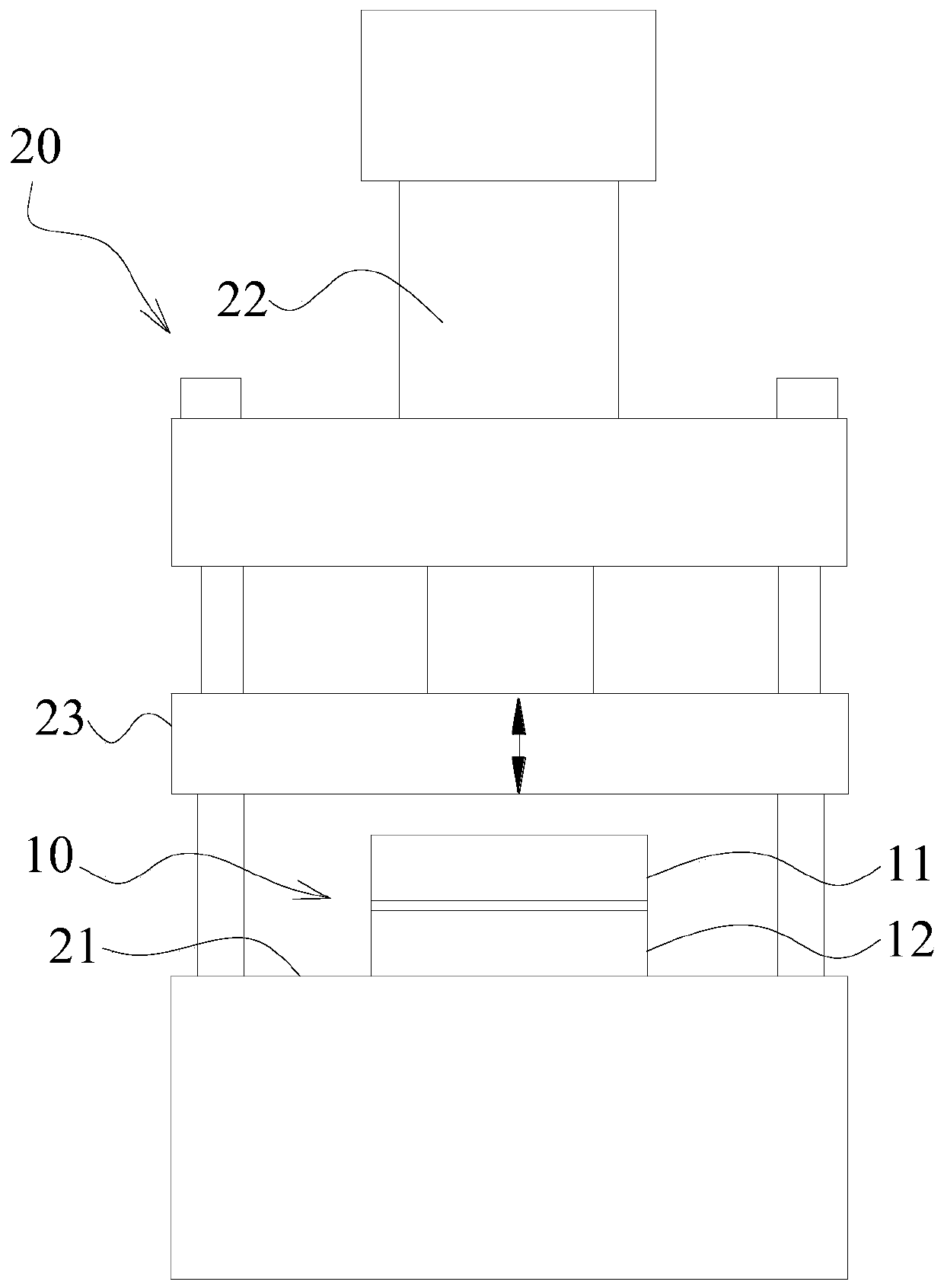

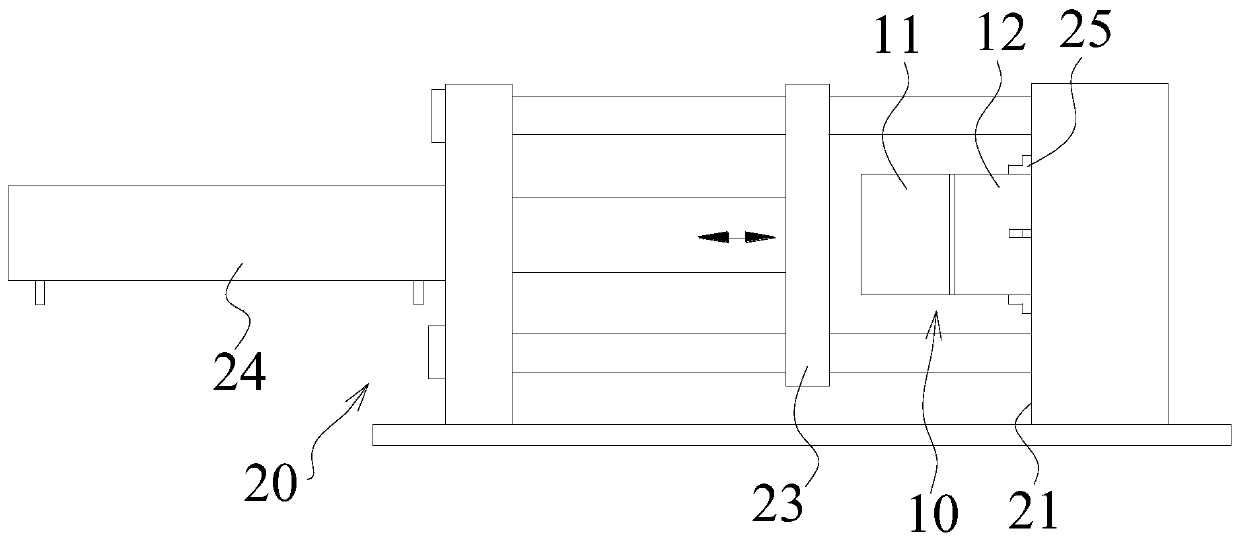

[0022] Hereinafter, the present invention will be further described with reference to the drawings and specific implementations. It should be noted that, provided that there is no conflict, the following embodiments or technical features can be combined to form new embodiments. .

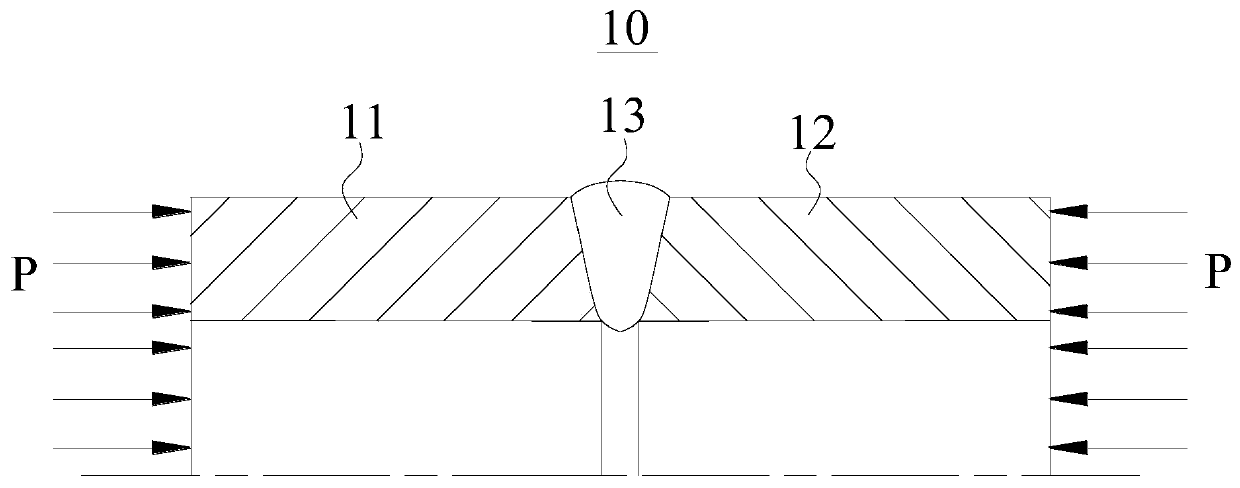

[0023] Such as Figure 1-3 As shown, this embodiment provides a process for reducing the residual stress of the butt weld of a thick-walled cylinder of dissimilar metals, which includes the following steps:

[0024] Pressurizing step: apply axial pressure to the butt weld 13 of the thick-walled cylinder of dissimilar metal to cause the metal in the weld zone to produce transverse compression and radial extension plastic strain. The transverse compression is the axial compression, so that the weld and its vicinity The residual tensile stress in the area is relaxed, so that the residual tensile stress level in the butt weld 13 of the thick-walled cylindrical body of the dissimilar metal can be reduced.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com