Method for manufacturing boreholes, components and fuel injectors

A fuel injector and component technology, which is applied in the field of manufacturing drilling holes, can solve problems such as strength reduction and difficulty, and achieve the effect of increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

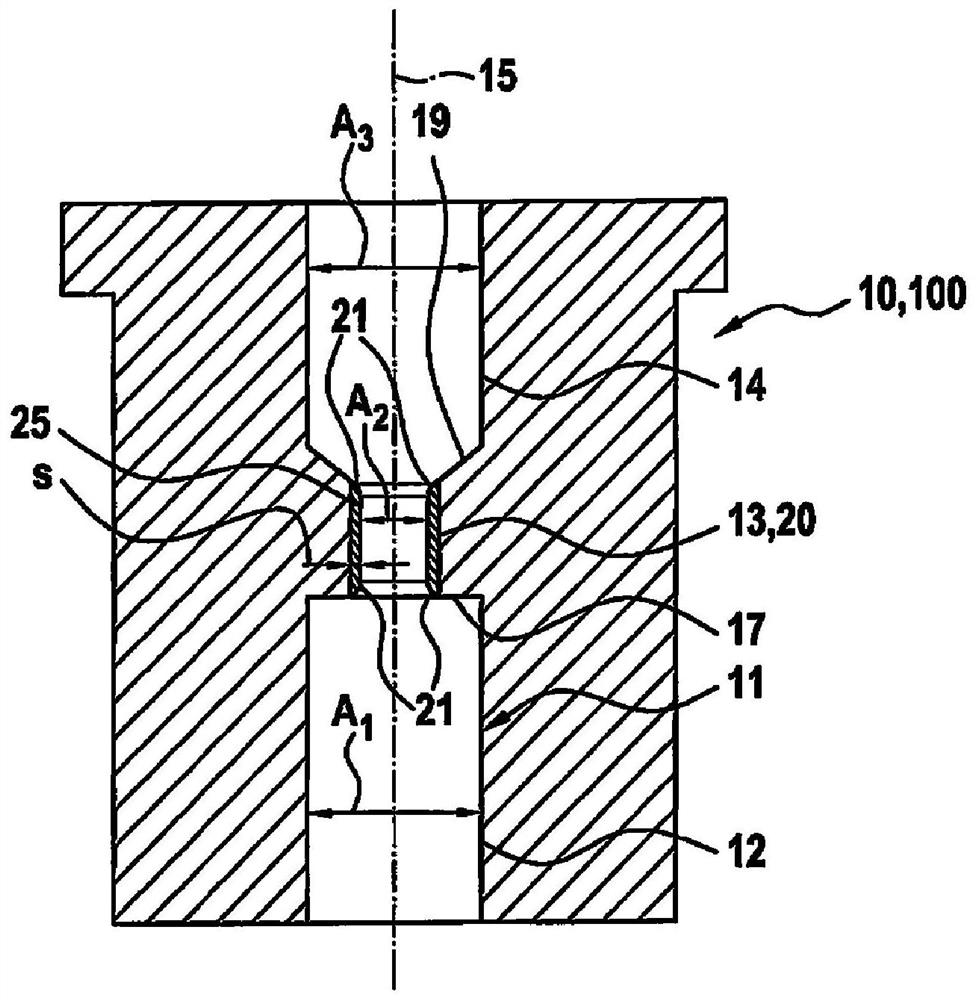

[0019] figure 1 shows in simplified form a valve part 10 made of steel of an otherwise not shown fuel injector 100 which is used as a so-called common rail system for injecting fuel into the combustion chamber of an internal combustion engine component. The internal combustion engine is a self-igniting internal combustion engine, wherein the system pressure also prevailing in the region of the valve part 10 is preferably greater than 2000 bar.

[0020] The valve element 10 , which is arranged inside the not-shown housing of the fuel injector 100 , serves in a known manner to control the entry of fuel flowing out of a so-called control chamber into the low-pressure region of the fuel injector 100 in order to thereby influence the nozzle needle. exercise. Purely by way of example, reference is made to DE 10 2012 219 657 A1 of the applicant with regard to the basic structure and mode of function of such a fuel injector 100 .

[0021] The valve part 10 has an outlet opening 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com