Method for reinforcement of metal surface by large area laser shock

A laser shock strengthening, metal surface technology, applied in the field of laser processing, can solve the problems of workpiece warping, affecting the impact effect, destroying the absorption layer, etc., to avoid damage, improve bending fatigue strength, and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

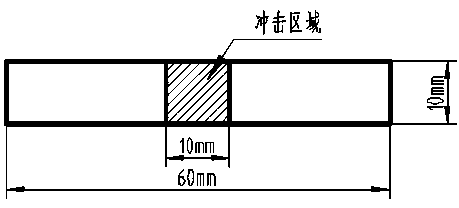

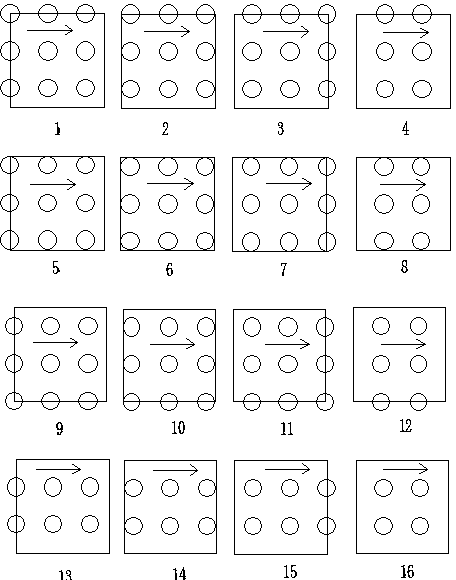

[0027] Example 1, such as figure 2 Laser shock strengthening is performed on the central 10mm×10 mm area of Ti6342 of 60mm×10 mm×2 mm, using a circular spot, and adjusting the laser parameters: laser energy 3J, pulse width 27ns, spot diameter 4mm, energy density 3.5GW / cm 2 , choose 50% lapping rate, repetition frequency 0.5Hz, double-sided shocking method.

[0028] Clamp the workpiece on the cage, use aluminum foil as the absorption layer, the nozzle hits the sample with water to form a water curtain as the constraint layer, move the X-Y table to change the impact position, the specific impact method is as follows figure 2As shown, 121 light spots are divided into 16 layers for impact. Take the corner of the area to be impacted as the reference point, and use the reference point as the starting point of the first layer of impact. After the initial point impact is completed, control the X-Y table to move horizontally so that the distance between the centers of adjacent lig...

Embodiment 2

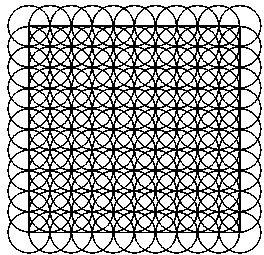

[0029] Example 2, such as figure 1 Perform laser shock strengthening on the central 10mm×10 mm area of 60mm×10 mm×2 mm Ti6342; use a square spot, adjust the laser parameters as follows: laser energy 13J, pulse width 15ns, spot side length 3mm, overlap rate selection 10% , the repetition frequency is 0.5Hz, and the impact method is double-sided impact.

[0030] Clamp the workpiece on the cage, use aluminum foil as the absorption layer, the nozzle hits the sample with water to form a water curtain as the constraint layer, and move the X-Y table to change the impact position; the specific impact method is as follows image 3 As shown, 25 light spots are divided into 9 layers for impact. Take the corner of the area to be impacted as the reference point, use the reference point as the starting point of the first layer of impact, and align the center of the rectangular spot with the starting point. After completing the starting point impact, control the X-Y table to move horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com