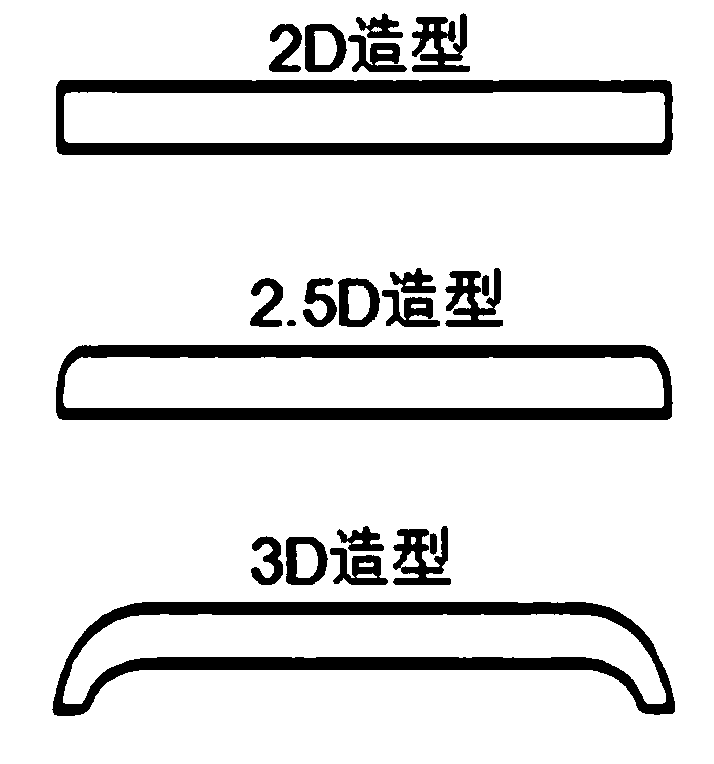

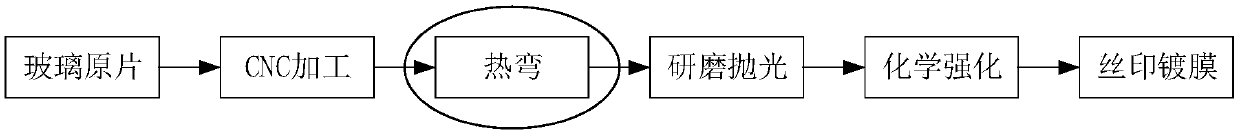

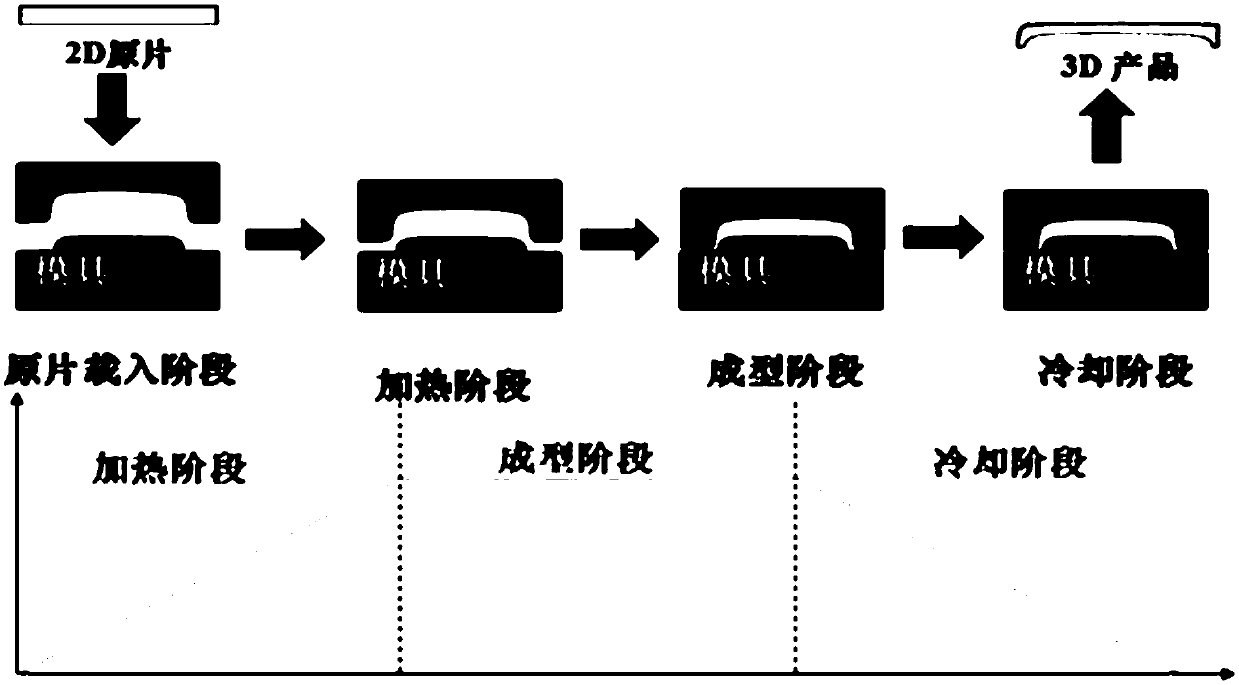

Mobile phone cover plate glass capable of meeting requirements of 5G communication and 3D compression molding and process method

A technology of molding and process method, which is applied in glass tempering, glass pressing, glass molding, etc., can solve the problems of high softening point temperature and dielectric constant, insufficient hot bending molding process, etc., and improve the surface quality of glass. , The effect of reducing the loss of 5G high-frequency transmission signal and prolonging the service life of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Physical and chemical process performance and chemical strength performance testing method and instrument of the present invention are as follows:

[0089]The elastic modulus is measured according to GB / T 7962.6-2010 "Test Methods for Colorless Optical Glass Part 6: Young's Modulus, Shear Modulus and Poisson's Ratio";

[0090] Density measurement adopts GB / T 7962.20-2010 "Test Methods for Colorless Optical Glass Part 20: Density";

[0091] The measurement of the average linear thermal expansion coefficient adopts GB_T 16920-2015 "Determination of the average linear thermal expansion coefficient of glass";

[0092] The surface tension measurement refers to the foreign language "Research on the Measurement Method of Surface Tension of Glass Melt under High Temperature Conditions" published by Tian Yingliang et al., Proceedings of China Society of Metrology and Testing, September 2013;

[0093] The measurement of dielectric constant adopts SJ / T 11043-1996 "Test method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com