Method for heating titanium blank by using continuous heating furnace

A heating furnace, continuous technology, used in the field of titanium slab heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

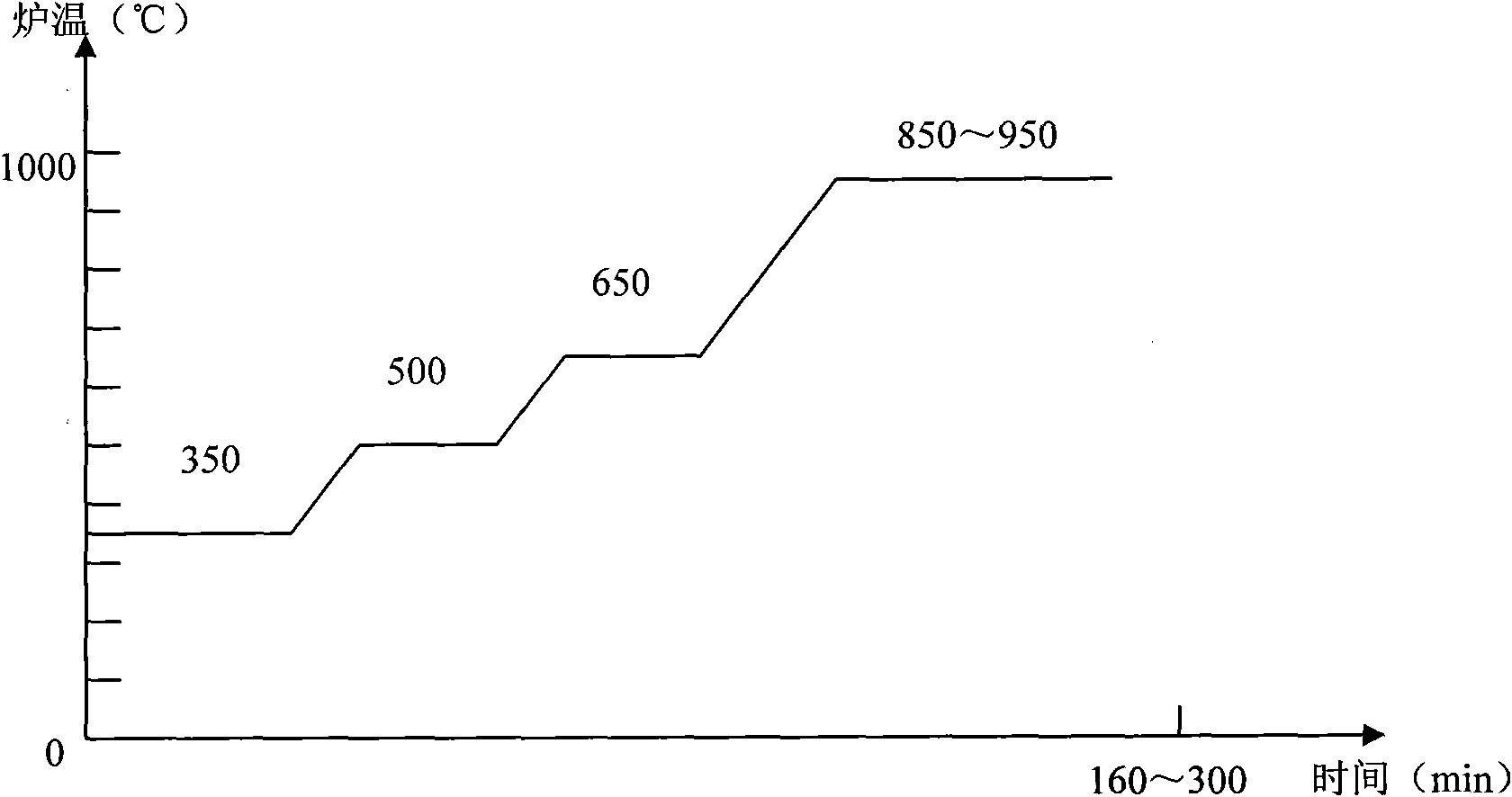

[0009] The invention provides a method for heating a titanium billet with a continuous heating furnace, which is characterized in that the titanium billet is heated to 800-900°C while avoiding a high-temperature flame area by means of radiation and convection.

[0010] The titanium billet is a titanium billet with a thickness of 150-250 mm. Including titanium billets and their alloy billets.

[0011] Preferably, the atmosphere in the furnace is controlled, and the atmosphere in the furnace is controlled to be a slightly oxidizing atmosphere. The micro-oxidizing atmosphere is to control the residual oxygen content between 0.2% and 2%.

[0012] Make the atmosphere in the furnace a slightly oxidizing atmosphere to avoid hydrogen absorption or serious oxidation of titanium at high temperatures. The atmosphere control in the furnace is realized by adjusting the ratio of air and mixed gas reasonably.

[0013] Furnace pressure is controlled at 10Pa ~ 30Pa, to avoid excessive consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com