Forging waste heat isothermal normalizing device and method

A technology of isothermal normalizing and forging waste heat, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problem of lower end-use performance of carburized steel parts, coarse austenite grains, and reduced machining performance of forging billets And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

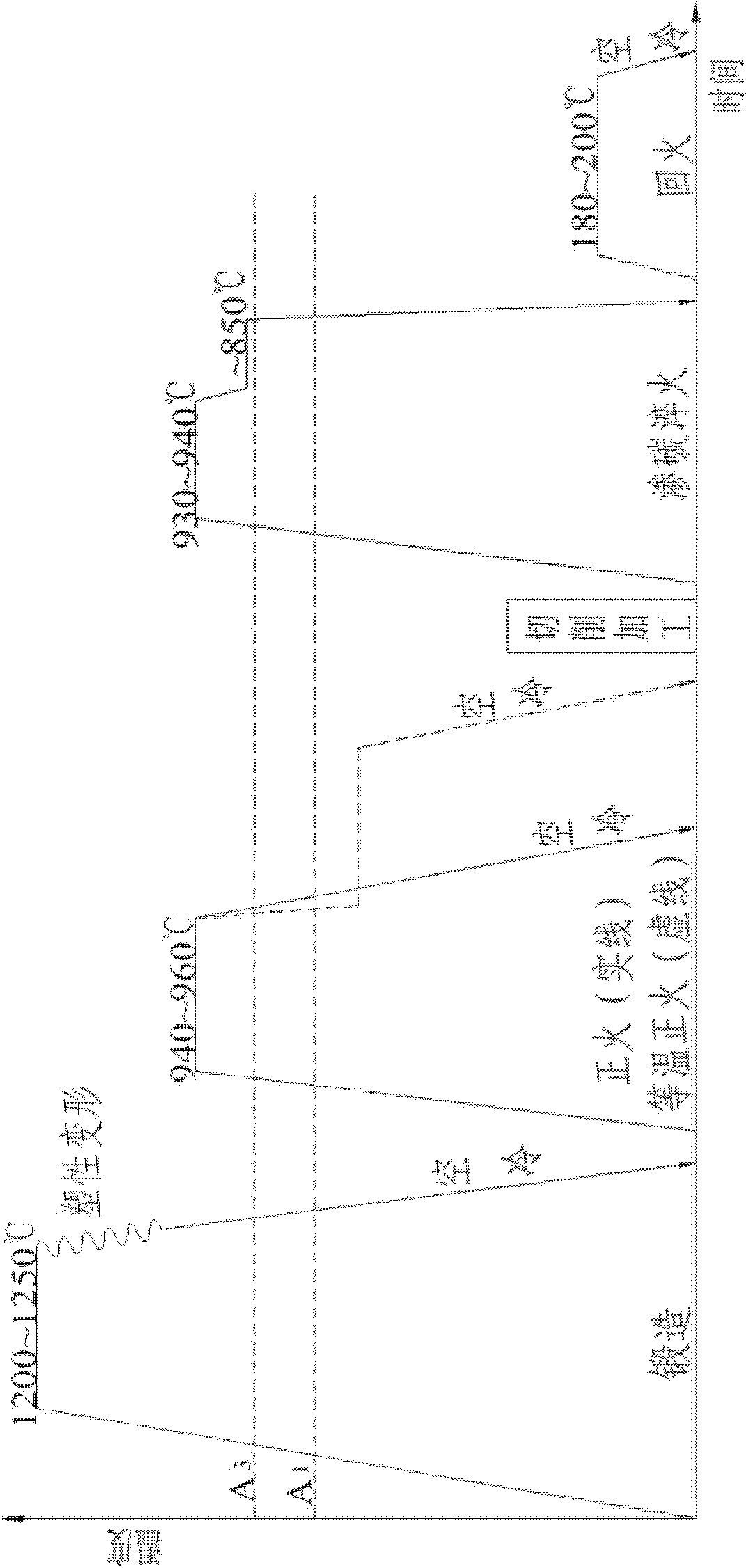

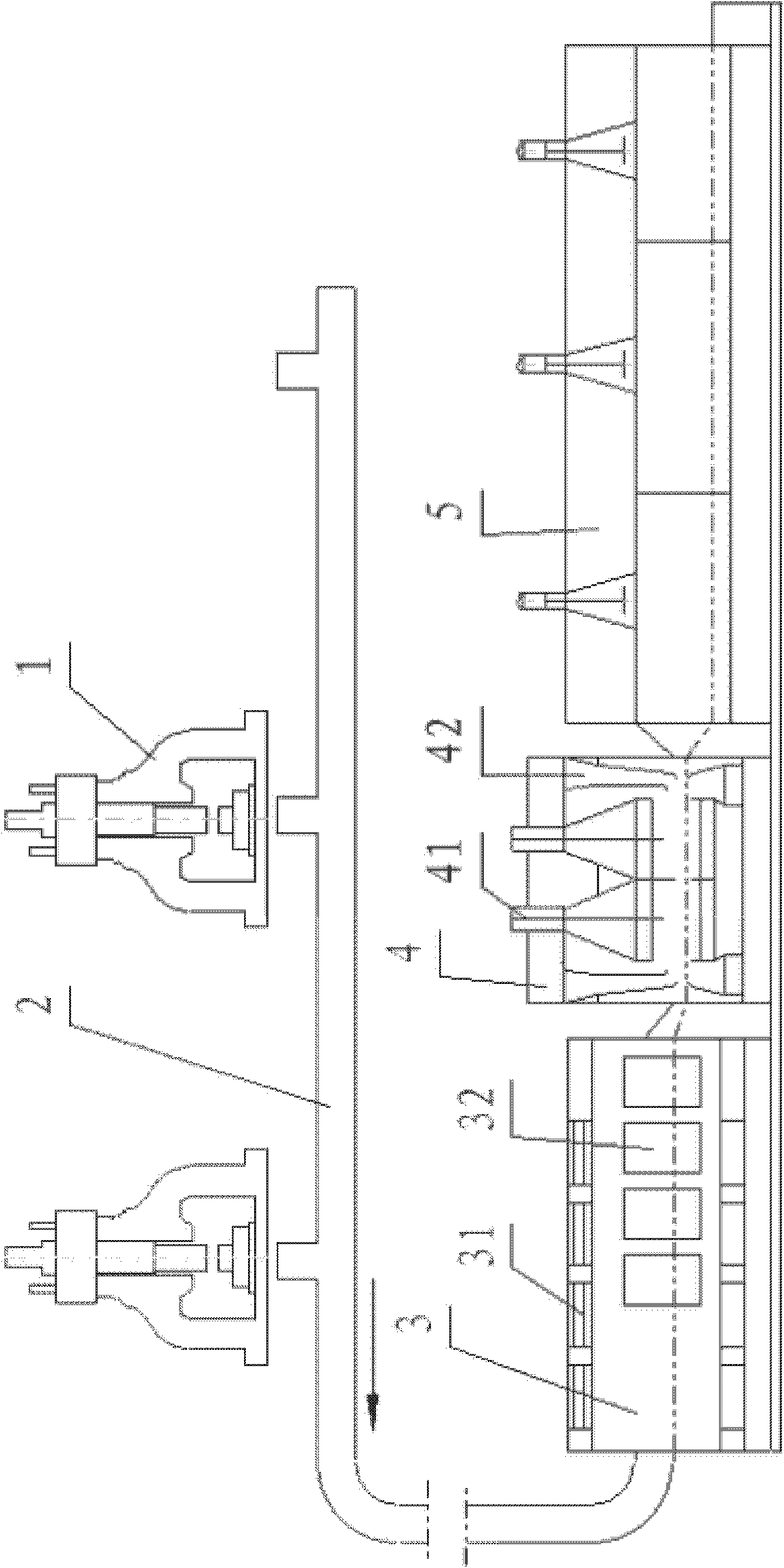

Method used

Image

Examples

example 1

[0097] 20CrMnTi steel was used for the gear forging billet used in the test, and the actual chemical composition of the batch of forging billets was determined to be wt%: 0.186C, 0.25Si, 1.05Mn, 0.020S, 0.015P, 1.02Cr, 0.15Ti. The effective thickness of the forging (forging billet) is: 30mm; the required hardness is HB165-185, the microstructure is F (ferrite) + P (pearlite), without B (bainite) and M (martensite).

[0098] Enter the actual chemical composition, effective thickness and required hardness of the forged billet into the calculation system of the above formula to obtain:

[0099] Pre-cooling temperature T1=800°C, pre-cooling temperature residence time t1=2min, select pre-cooling speed V 1 =5°C / min;

[0100] Forced cooling speed V 2 =60°C / min, strong cooling temperature T 2 = 610°C;

[0101] isothermal temperature T iso =610°C, isothermal time t iso = 150 min.

[0102] Input the calculated process parameters into the control system of the device and run the d...

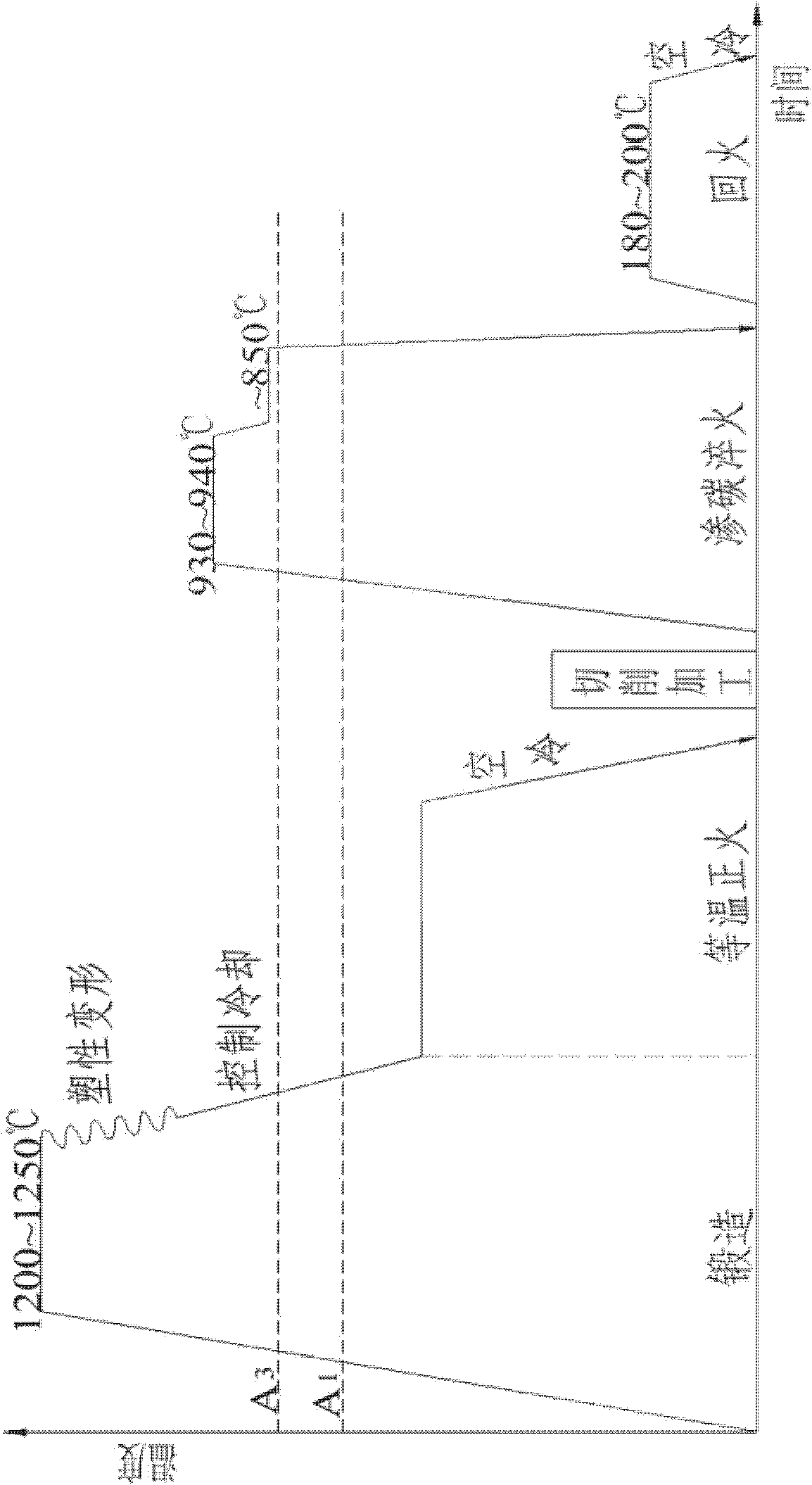

example 2

[0104] In this example, the control system in the waste heat isothermal normalizing device of the present invention communicates with the process parameter calculation expert software to directly control the operation of the device after inputting the actual chemical composition, effective thickness and hardness requirements of the forging billet.

[0105] 20CrMnMo (SCM22) steel was selected for the test gear forging billet, and the actual chemical composition of the batch of forging billet was detected as wt%: 0.201C, 0.25Si, 0.65Mn, 0.03S, 0.02P, 1.10Cr, 0.25Mo. The effective thickness of the workpiece (forging billet) is: 30mm; the required hardness is HB160-180, and the microstructure is F+P.

[0106] Enter the actual chemical composition, effective thickness and required hardness of the forged billet into the calculation system of the above formula to obtain:

[0107] Pre-cooling temperature T 1 =810°C, pre-cooling temperature residence time t 1 =(5)min, select the pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com