Preparation method of chloromethyl styrene resin

A technology of chloromethyl styrene and polystyrene resin, which is applied in the field of preparation of chloromethyl styrene resin, can solve the problems of high production cost, and achieve the effect of low production cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

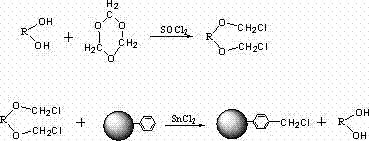

Method used

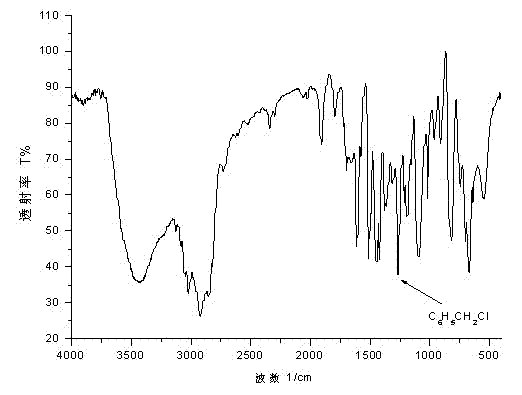

Image

Examples

Embodiment 1

[0034] A preparation method of chloromethyl styrene resin, specifically comprising the following steps:

[0035] (1) Add 20g of paraformaldehyde, 190g of solvent 1 and 30g of dihydric alcohol into the reaction vessel in sequence, react for 12 hours in the presence of dry hydrogen chloride gas, and then carry out vacuum distillation under the condition that the pressure is lower than 5 mmHg Purify to obtain 31g of long-chain chloromethyl ethers containing two chloromethyl groups, with a yield of 57%;

[0036] The solvent 1 is ethylene dichloride;

[0037] Described dihydric alcohol is 1,6-hexanediol;

[0038] (2), take 15g of long-chain chloromethyl ether obtained in step (1), add 20g of dry macroporous polystyrene resin balls, 35g of solvent 2, and 2.4g of catalyst, and carry out chloromethylation reaction at room temperature under stirring conditions 14h, the catalyst was added in three times, that is, 0.8g was added every 4.5h. After the reaction, the reaction solution was...

Embodiment 2

[0048] A preparation method of chloromethyl styrene resin, specifically comprising the following steps:

[0049] (1) Add 20g of paraformaldehyde, 200g of solvent 1 and 27g of diol into the reaction vessel in sequence, react for 6 hours in the presence of dry hydrogen chloride gas, and then carry out vacuum distillation under the condition that the pressure is lower than 5 mmHg Purify, obtain 27g long-chain chloromethyl ether, productive rate 51%;

[0050] The solvent 1 is dichloromethane;

[0051] Described dihydric alcohol is 1,6-hexanediol;

[0052] (2) Take 10g of long-chain chloromethyl ether prepared in step (1), add 5g of dry gel polystyrene resin balls, 54g of solvent 2, and 1.8g of catalyst, and stir at room temperature for chloromethylation reaction for 12h After the reaction, the reaction solution is filtered with a sand core funnel to remove the solvent (including solvent 1 and solvent 2), glycol and unreacted long-chain chloromethyl ether to obtain resin balls;

...

Embodiment 3

[0061] A preparation method of chloromethyl styrene resin, specifically comprising the following steps:

[0062] (1) Add 20g of paraformaldehyde, 300g of solvent 1, 30g of dihydric alcohol and 110g of p-toluenesulfonyl chloride into the reaction vessel in sequence, stir and react for 24 hours, and then carry out vacuum distillation and purification under the condition that the pressure is controlled below 5 mmHg , obtain 24g long-chain chloromethyl ether, productive rate 47%;

[0063] The solvent 1 is ethylene dichloride;

[0064] The dihydric alcohol is 1,8-octanediol;

[0065] (2) Take 15g of the long-chain chloromethyl ether prepared in step (1), add 10g of dry macroporous polystyrene resin balls, 40ml of solvent 2, and 2.4g of catalyst, and carry out the chloromethylation reaction under ultrasonic conditions at room temperature for 8 hours , the catalyst was added in three times, adding 0.8g every 2h. After the reaction, the reaction solution was filtered with a sand cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com