Method for manufacturing monolithic bipolar membrane

A bipolar membrane, manufacturing method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. To achieve the effect of easy large-scale industrial production, lower impregnation temperature, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

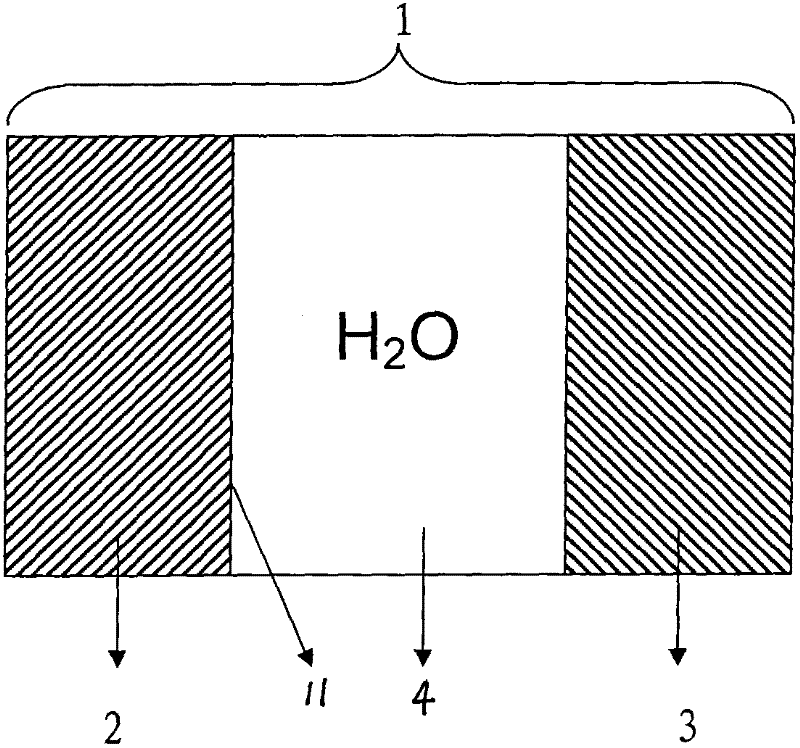

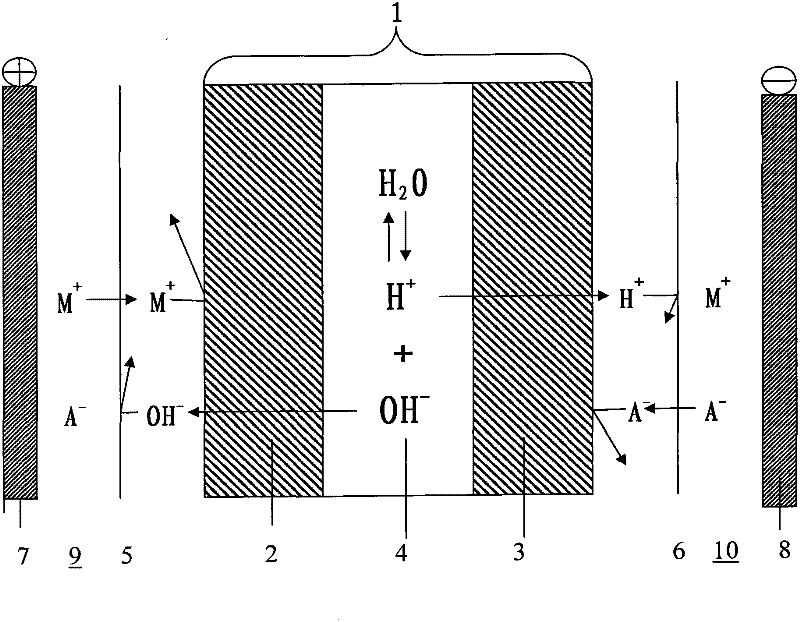

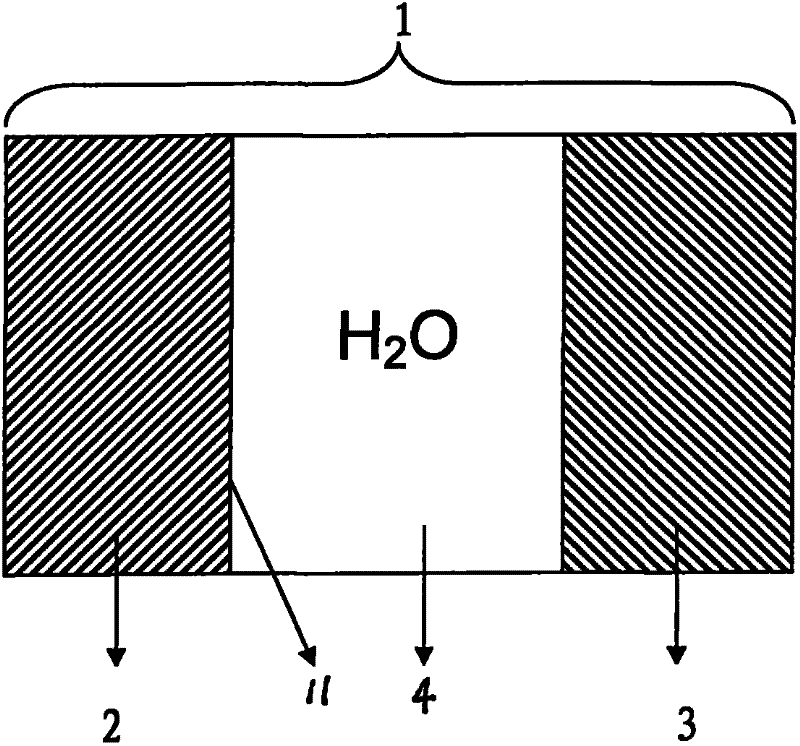

Image

Examples

Embodiment 1

[0030] 1, the preparation of raw material film: with 3 kilograms of commercially available polyethylene granules (melt index 0.75-1.2) and 2 kilograms of commercially available ethylene and octene copolymer (brand POE-8003) elastomer containing 20% octene in Mix in a granulator, melt (temperature 190-220° C.) and granulate to obtain a granular blend. Next, heat the granular blend on a casting machine (temperature 190-250° C.) to melt, and cast to obtain a blended gold film of 0.18±0.01 mm, which is a self-made raw material film.

[0031] Cut the self-developed polyethylene and ethylene and octene copolymer elastomer blend film into 800mm×400mm, with a thickness of 0.18mm, and put multiple sheets together with styrene, divinylbenzene (crosslinking agent, the content is benzene 5% of ethylene) and benzoyl peroxide (initiator, content is 0.5%-1% of styrene amount) in the stainless steel tank of the solution that forms, at room temperature (about 25 ℃) leave standstill 3 hours, ...

Embodiment 2

[0036] Adopt polyethylene and ethylene and octene copolymer elastomer (containing 20% octene) blended film (elastomer content is 40%), operation procedure is according to embodiment 1. The impregnation time of the basement film was 2 hours, and the impregnation rate of the basement film was 60%. Sulfonation conditions, chloromethylation and amination conditions are all the same as in Example 1. The negative ion exchange capacity of the obtained bipolar membrane was 1 meq / g dry film, the positive ion exchange capacity was 1.2 meq / g dry film, and the transmembrane voltage drop was 1.9V.

Embodiment 3

[0038] Adopt polyethylene and ethylene and octene copolymer elastomer (containing 45% octene) blended film (elastomer content is 45%), the operating steps are as in Example 1. The impregnation temperature of the base film is 30° C., the time is 3 hours, and the impregnation rate of the base film is 70%. Basement film sulfonation temperature is 80°C, time is 5 hours, chloromethylation temperature is 50°C, time is 16 hours, aminated with 30% trimethylamine aqueous solution containing 6% dimethylamine, temperature is 35°C, time is 10 hours, to obtain The bipolar membrane has a positive ion exchange capacity of 1.6 meq / g dry film, a negative ion exchange capacity of 0.7 meq / g dry film, and a transmembrane voltage drop of 1.8V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com