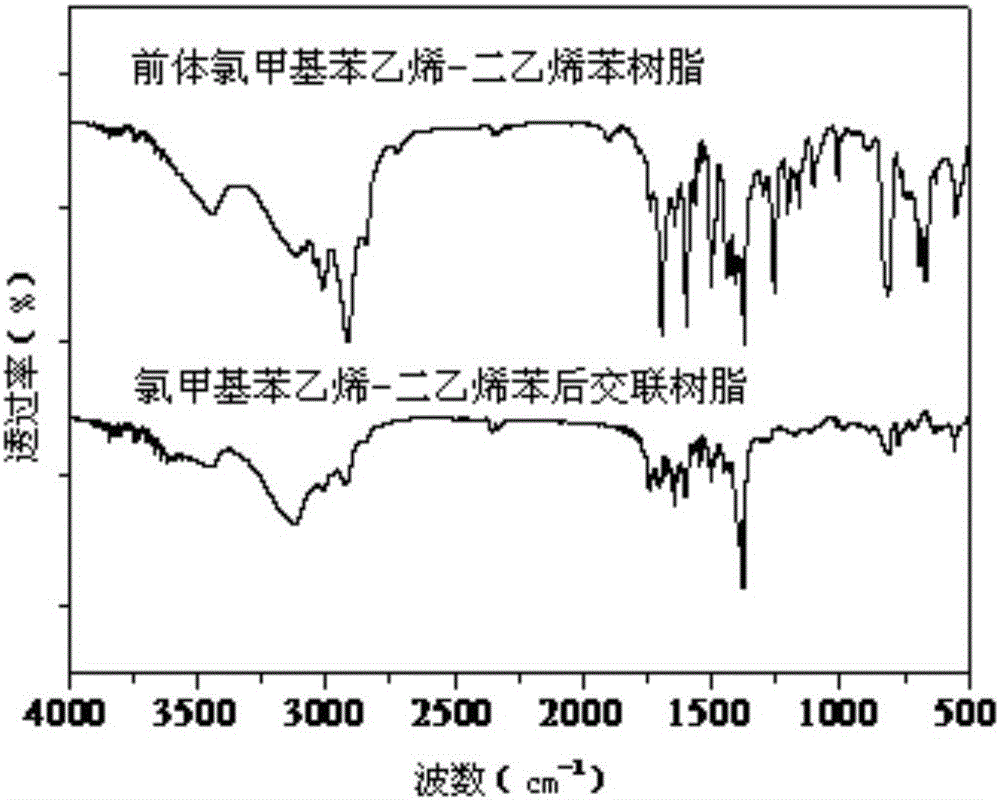

Hyper cross-linking resin as well as preparation method and application thereof

An ultra-high cross-linked resin and resin technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve internal structure inhomogeneity, difficult control of pore structure, and poor decolorization effect and other problems, to achieve the effect of simplifying the production method and good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

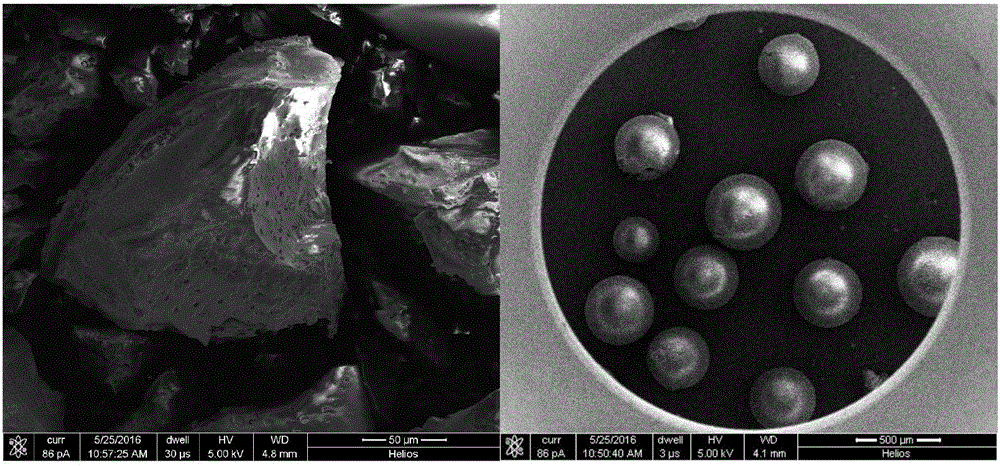

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: The preparation method of chloromethylstyrene-divinylbenzene gel type resin with 2% crosslinking degree specifically comprises the following steps:

[0044](1) Water-to-oil ratio=8:1, the water phase is composed of 50ml of deionized water, 0.1g of polyvinyl alcohol, 1.65g of sodium chloride, and 0.08g of hydroquinone; the composition of the oil phase is 6.34 p-chloromethylstyrene g, divinylbenzene 0.129g, azobisisobutyronitrile 0.0646g; before adding the water phase, pass argon for 30 minutes in advance, add the oil phase to the water phase at 50°C and mix for 1 hour, raise the temperature to 80°C for 20 hours, and react in the later stage Raise the temperature to 110°C for aging for 2 hours and then cool to room temperature naturally.

[0045] (2) The obtained product was repeatedly washed 3 times with deionized water heated to 80°C, solidified with methanol and washed 3 times, then Soxhlet extracted with ethanol for 8 hours, at a relative vacuum lower th...

Embodiment 2

[0049] Embodiment 2: the preparation method of hole type chloromethyl styrene resin specifically comprises the following steps:

[0050] (1) Water-to-oil ratio=8:1, the water phase is composed of 50ml of deionized water, 0.1g of polyvinyl alcohol, 1.65g of sodium chloride, and 0.08g of hydroquinone; the composition of the oil phase is 5.498g of chloromethyl styrene , divinylbenzene 0.97g, azobisisobutyronitrile 0.0646g, toluene 6.1ml; before adding the water phase, pass argon for 30 minutes in advance, add the oil phase to the water phase at 50°C and mix for 1 hour, then raise the temperature to 80°C for 20 hours In the later stage of the reaction, the temperature was raised to 110° C. for aging for 2 h, and then naturally cooled to room temperature.

[0051] (2) The obtained product was repeatedly washed 3 times with deionized water heated to 80°C, solidified with methanol and washed 3 times, then Soxhlet extracted with acetone for 8 hours to remove the porogen, and the relat...

Embodiment 3

[0055] Embodiment 3: the preparation method of 10% cross-linking degree chloromethyl styrene-divinyl benzene resin, specifically comprises the following steps:

[0056] (1) Water-to-oil ratio=8:1, the water phase is composed of 50ml of deionized water, 0.1g of magnesium hydroxide, 1.65g of sodium chloride, and 0.08g of methylene blue; the composition of the oil phase is 5.821g of p-chloromethylstyrene, two Vinylbenzene 0.647g, dibenzoyl peroxide

[0057] 0.0646g; pass argon gas for 30 minutes in advance before adding the water phase, add the oil phase to the water phase at 50°C and mix for 1 hour, raise the temperature to 60°C and react for 20 hours, then raise the temperature to 110°C for aging for 2 hours in the later stage of the reaction, then cool to room temperature naturally.

[0058] (2) The obtained product was repeatedly washed 3 times with deionized water heated to 80°C, solidified with methanol and washed 3 times, then Soxhlet extracted with ethanol for 8 hours, at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com