Synthetic method of high temperature-resistant strongly basic anion exchange resin

A technology of exchange resin and synthesis method, which is applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of limiting the application range of strong base anion exchange resin, loss of activity of strong base anion exchange resin, etc., and achieve simple production process , good thermal stability and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: a kind of synthetic method of high temperature resistant strongly basic anion exchange resin, it is characterized in that: adopt cross-linked polystyrene white ball as skeleton, adopt chloromethyl ether to connect on white ball skeleton by Fourier reaction as alkylating agent Benzyl chloride, and then carry out amination reaction with alkylamine containing long carbon chain to obtain strong basic anion exchange resin.

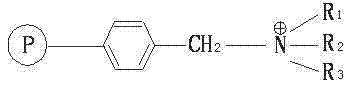

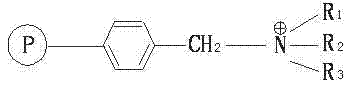

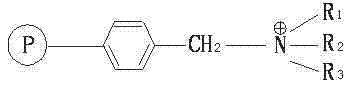

[0017] The cross-linked polystyrene white ball skeleton is gel type or macroporous type, and the cross-linking degree is 2%~20%. The chlorine content of the cross-linked polystyrene white ball skeleton is 5%~25% after chloromethylation. Adopt the tertiary amine that contains long carbon chain alkyl group to carry out amination reaction, obtain the strongly basic anion exchange resin containing long carbon chain alkylammonium group, its structural formula is as follows:

[0018]

[0019] Among them, P is a cross-linked polystyrene skelet...

example 1

[0025] Example 1: In a 1000ml three-neck flask equipped with mechanical stirring, a spherical condenser and a thermometer, add 100g of gel-type polystyrene white balls with a cross-linking degree of 7% and 600ml of chloromethyl ether, start stirring, and expand at room temperature 4h. After the expansion is completed, add 30g of zinc chloride into the three-neck flask, heat it to 40°C in a water bath, and keep it warm for 15h. After the reaction is completed, use a vacuum pump to drain the mother liquor, take an appropriate amount of methanol and wash it several times, measure the chlorine content of the chlorine ball to be 17%, add 300ml of methylal to expand for 1 hour, then add 200ml of triethylamine, and heat to 40 in a water bath. ℃, keep warm for 20h, drain the mother liquor after the reaction, wash with pure water to pH=7, the measured strong base exchange capacity of the resin is 3.40mmol / g (dry), and the water content is 50.8%. Put this resin into a stainless steel t...

example 2

[0026] Example 2: The resin synthesis steps are the same as Example 1. The heat stability test of the resin is to place the high temperature resistant resin in a stainless steel tank filled with pure water, seal the stainless steel tank and place it in a constant temperature water bath at 90°C for 80 hours, and take a sample Re-measure the imposed exchange capacity of the resin to be 3.38mmol / g (dry), and calculate the loss rate of resin strong alkali exchange capacity to be 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com