Dedicated ion exchange resin for condensed water precision processing and preparation method thereof

A technology of ion exchange resin and condensate polishing treatment, which is applied in the chemical field to achieve the effect of high mechanical strength and good resistance to organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

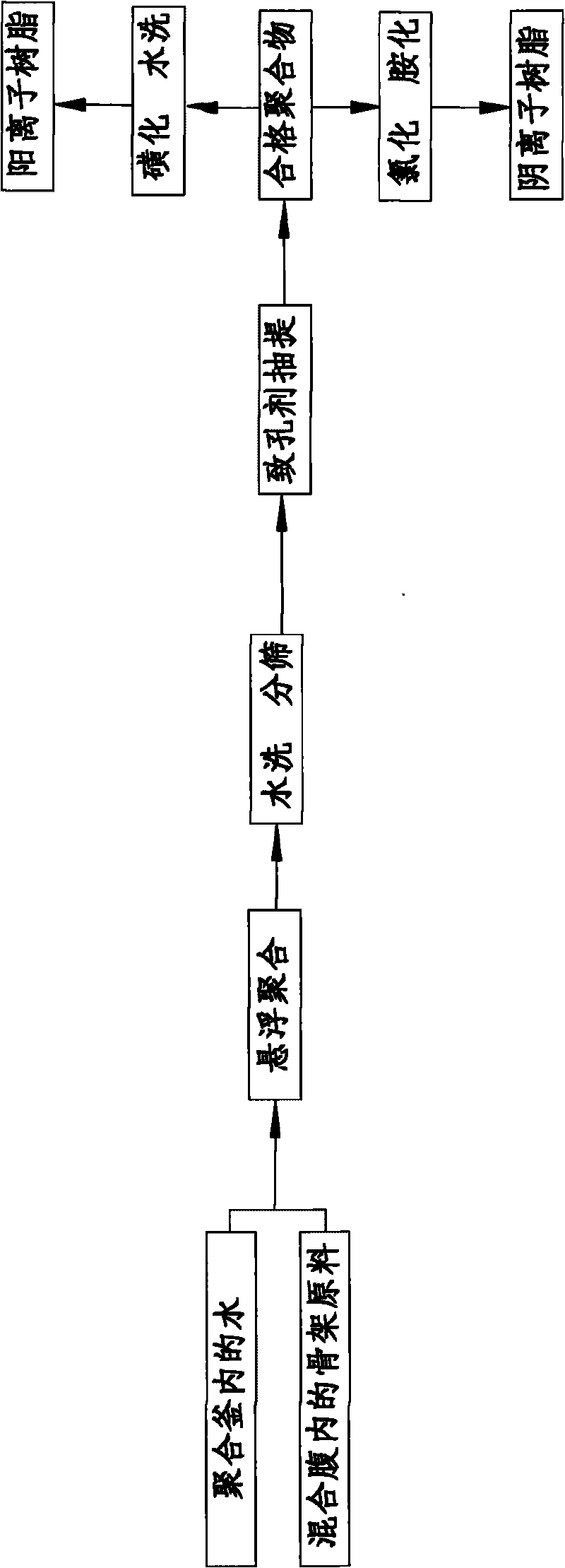

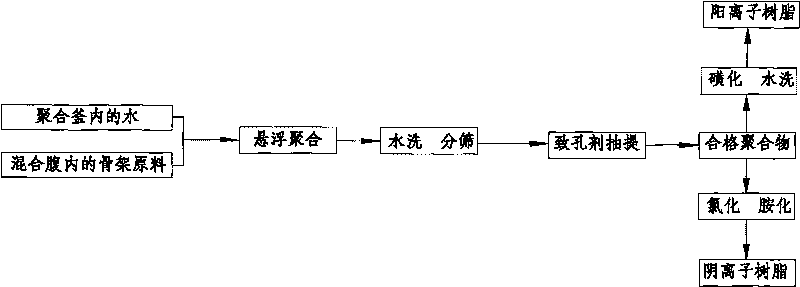

Method used

Image

Examples

Embodiment 1

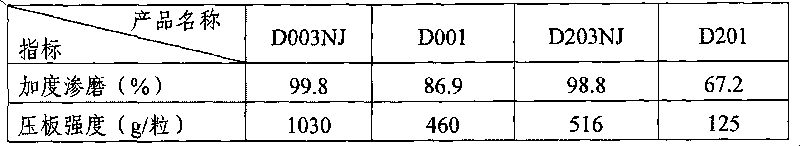

[0045] A special ion exchange resin for condensate polishing treatment, the resin includes a skeleton polymerized from styrene and divinylbenzene, and a cationic functional resin with concentrated sulfuric acid and dichloroethane as the main components is connected to the skeleton. group, or an anionic functional group with chloromethyl ether, trimethylamine and zinc chloride as the main components, characterized in that the cationic functional group and the anionic functional group also contain sodium hydroxide, Composite multi-component porogen and chain transfer agent, containing benzoyl peroxide, polyvinyl alcohol and solid paraffin in the composite multi-component porogen, containing cycloethane and sodium chloride in the chain transfer agent, the The shape of the ion exchange resin is spherical.

[0046] A preferred embodiment of the present invention is that, in the ion exchange resin, the content of benzoyl peroxide is set to 0.15%, the content of polyvinyl alcohol is ...

Embodiment 2

[0050] A kind of preparation method of special cation exchange resin for condensate polishing treatment, described preparation method comprises the steps:

[0051] 1. Aggregation operation:

[0052] 1. Check whether the polymerization kettle and mixing kettle are clean; whether the stirring blade is firm; whether the position is correct; whether there are adherents; whether the water, electricity, steam, vacuum, and vent valves are opened and closed normally; whether the thermometer is in good condition; whether the auxiliary equipment is in good condition .

[0053] 2. Check whether the scale is correct; whether the skeleton container is clean; accurately measure the skeleton raw materials styrene and divinylbenzene according to the ratio of the skeleton, and store them in the skeleton container. Accurately measure the solid wax, benzoyl peroxide, methylene blue (catalyst) and cyclohexane, and place them beside the mixing kettle for later use.

[0054] 3. Inhale the skeleto...

Embodiment 3

[0097] A kind of preparation method of special anion exchange resin for condensate polishing treatment, described preparation method comprises the steps:

[0098] 1. Polymerization operation: the same as the preparation method of the above-mentioned cation exchange resin for condensate polishing treatment.

[0099] 2. Extraction operation:

[0100] 1. Carefully check whether the equipment in use is in good condition and whether the valve is in good condition.

[0101] 2. Inhale 2500kg of toluene into the high level tank.

[0102]3. Put 1500kg of the polymer (white ball) that has been baked and screened into the extraction kettle, and put 2500kg of toluene from the high-level tank into the extraction kettle, start the stirrer in the extraction kettle to stir, and heat up to 75±5 At ℃, keep warm for 1 hour ± 15 minutes, then put the toluene into the evaporation recovery kettle through the valve, then put the toluene in the high level tank into the extraction kettle again, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com