Method of two-stage continuous polymerization production of petroleum resin

A technology of petroleum resin and polymerization kettle, which is applied in the field of two-stage continuous polymerization to produce C5 petroleum resin, which can solve the problems of low productivity, cumbersome operation and heavy labor in batch single-pot polymerization, and achieve operability and uniform mixing , Improve the effect of resin quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

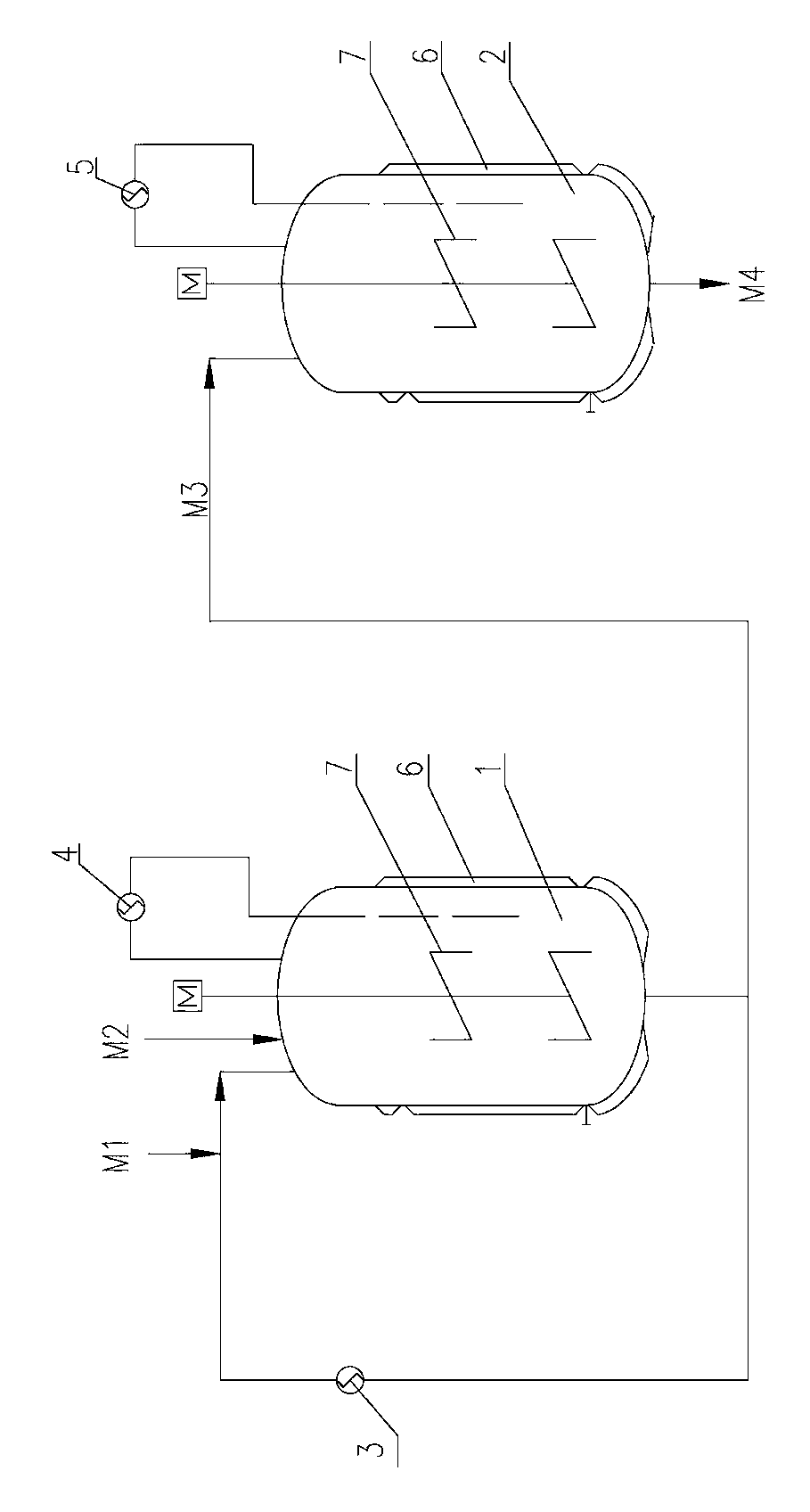

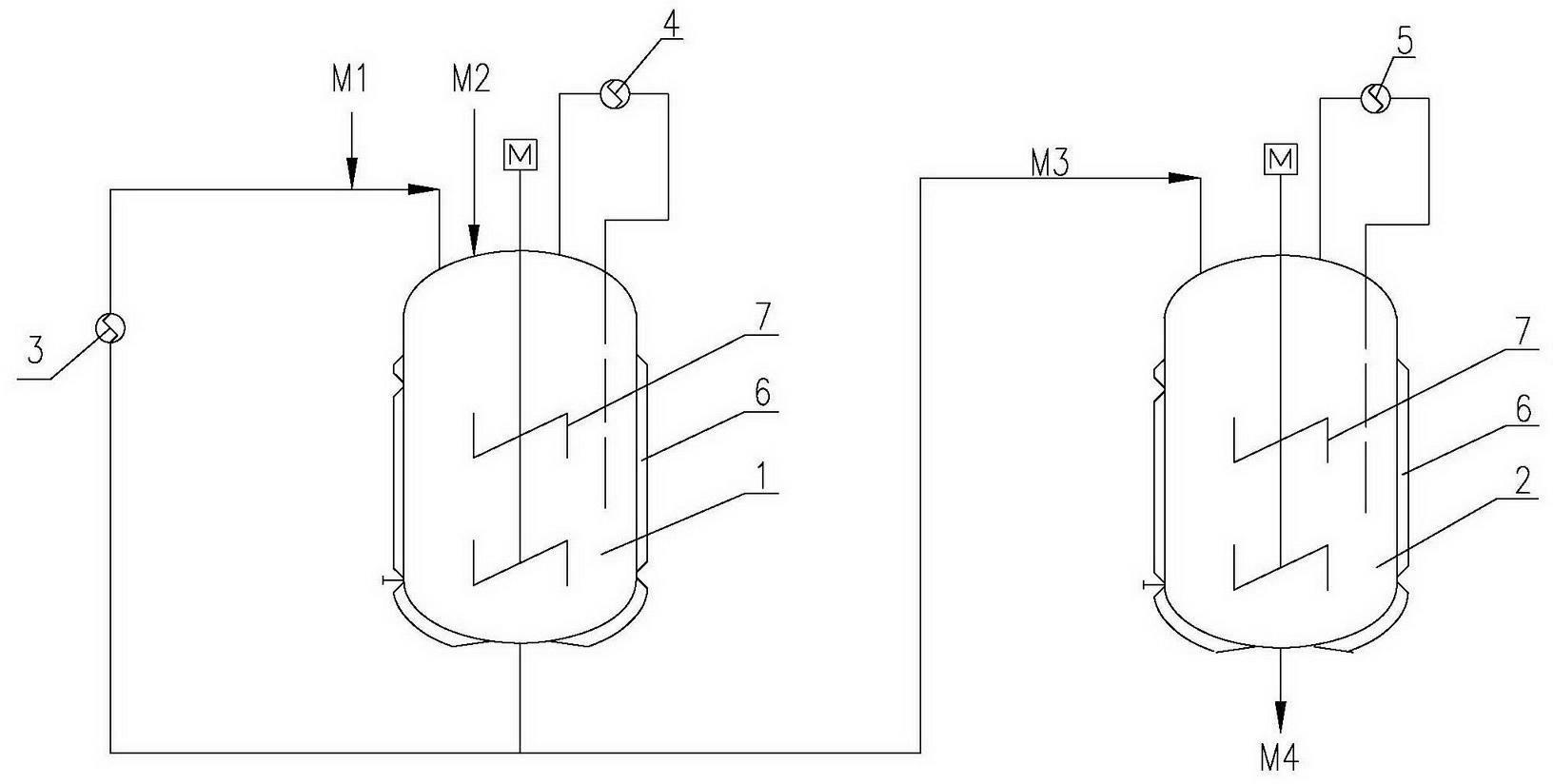

[0015] As shown in the figure, both the polymerization kettle 1 and the delayed reaction kettle 2 are carbon steel kettles with a stirrer 7 inside and a circulating water jacket 6 outside, and their volumes are both 15 liters. The material residence time of the first and second stages of polymerization can be controlled by controlling the feed amount of the polymerization kettle 1, the liquid level of the polymerization kettle 1 and the delay reaction kettle 2; the circulating water volume of the circulating water jacket 6 of the polymerization kettle 1 and the external circulation heat exchange can be controlled The circulating water volume of the device 3 can control the polymerization reaction temperature of the first section; the cooling capacity of the condenser 4 can control the polymerization pressure of the first section. The temperature of the second-stage polymerization reaction can be controlled by controlling the water temperature and water volume in the circulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com