Colored polylactic acid particle and preparation method thereof

A technology for coloring polylactic acid and polylactic acid, which is applied in the field of colored polylactic acid particles and its preparation, and the coloring of polylactic acid, can solve the problems of limited application range, increased cost of raw materials, and increased investment costs of polylactic acid downstream application production enterprises. The effect of wide application range and reduction of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

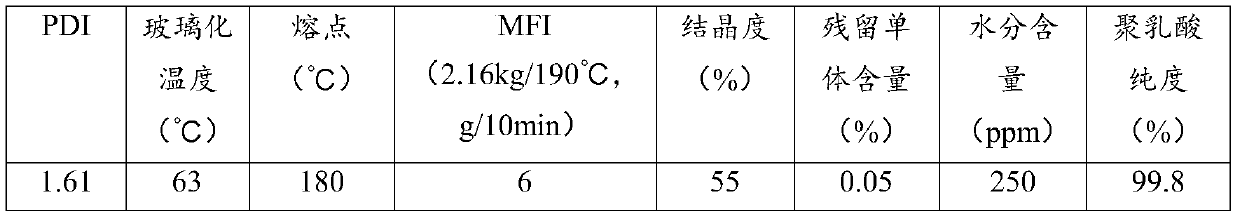

Embodiment 1

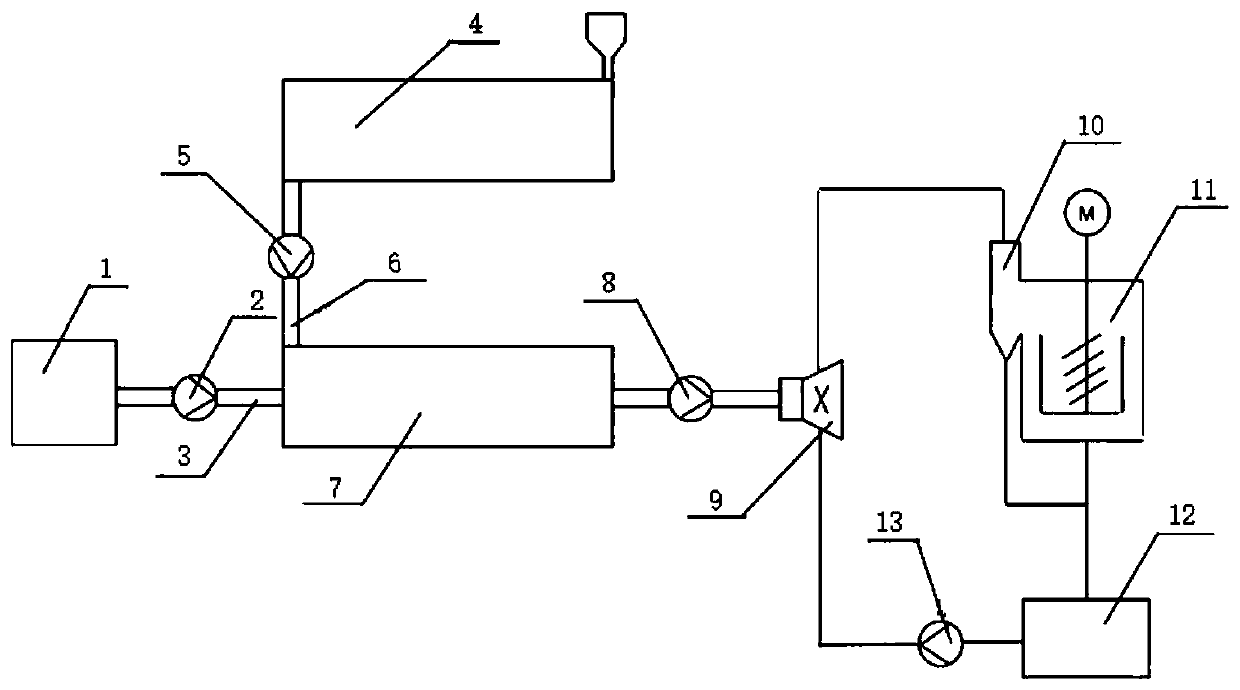

[0026] This embodiment adopts figure 1 The production device for colored polylactic acid particles shown produces colored polylactic acid particle products. details as follows.

[0027] The polylactic acid polymerization device 1 is polymerized to generate a colorless polylactic acid material in a molten state. The relative molecular weight of the colorless polylactic acid material is 170,000 g / mol.

[0028] Take the polylactic acid-based color masterbatch, the selection of the polylactic acid-based color masterbatch is determined according to the needs of downstream manufacturers, and what is selected in this embodiment is the polylactic acid-based sky blue masterbatch produced by Changzhou Baohong Color Masterbatch Co., Ltd., wherein The pigment content is 10%. The color masterbatch is put into the screw extruder 4, and heated to melt to obtain colored polylactic acid in molten state, that is, colored polylactic acid melt.

[0029] The colorless polylactic acid material ...

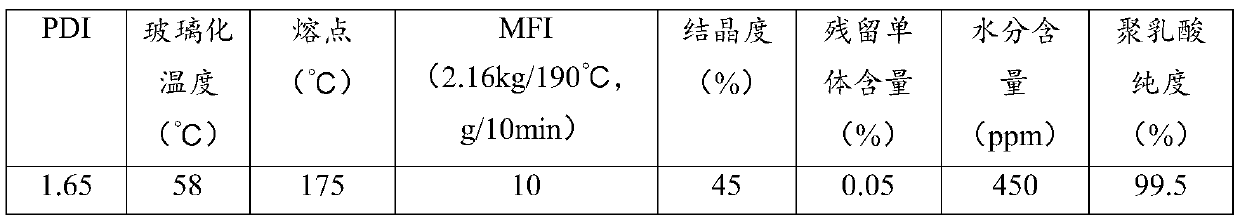

Embodiment 2

[0042] This embodiment adopts figure 1 The production device for colored polylactic acid particles shown produces colored polylactic acid particle products. details as follows.

[0043] The polylactic acid polymerization device 1 is polymerized to generate a colorless polylactic acid material in a molten state. The relative molecular weight of the colorless polylactic acid material is 150,000 g / mol.

[0044] Get the polylactic acid-based color masterbatch, the selection of the polylactic acid-based color masterbatch is determined according to the needs of downstream manufacturers. In this embodiment, the polylactic acid-based light yellow masterbatch produced by Changzhou Baohong Color Masterbatch Co., Ltd. is selected, wherein The pigment content is 20%. The color masterbatch is put into the screw extruder 4, and heated to melt to obtain colored polylactic acid in molten state, that is, colored polylactic acid melt.

[0045] The colorless polylactic acid material that is ...

Embodiment 3

[0058] This embodiment adopts figure 1 The production device for colored polylactic acid particles shown produces colored polylactic acid particle products. details as follows.

[0059] The polylactic acid polymerization device 1 is polymerized to generate a colorless polylactic acid material in a molten state. The relative molecular weight of the colorless polylactic acid material is 180,000 g / mol.

[0060] Get the polylactic acid-based color masterbatch, the selection of the polylactic acid-based color masterbatch is determined according to the needs of downstream manufacturers, and what is selected in this embodiment is the polylactic acid-based carbon black masterbatch produced by Changzhou Baohong Color Masterbatch Co., Ltd., wherein The pigment content is 10%. The color masterbatch is put into the screw extruder 4, and heated to melt to obtain colored polylactic acid in molten state, that is, colored polylactic acid melt.

[0061] The colorless polylactic acid materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com