In-situ polymerized organic-inorganic composite solid-state battery

A solid-state battery and inorganic composite technology, applied in the direction of secondary batteries, battery electrodes, battery components, etc., can solve the problems of difficult manufacturing and high interface impedance of secondary batteries, achieve close manufacturing process, improve lithium ion transmission capacity, The effect of increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

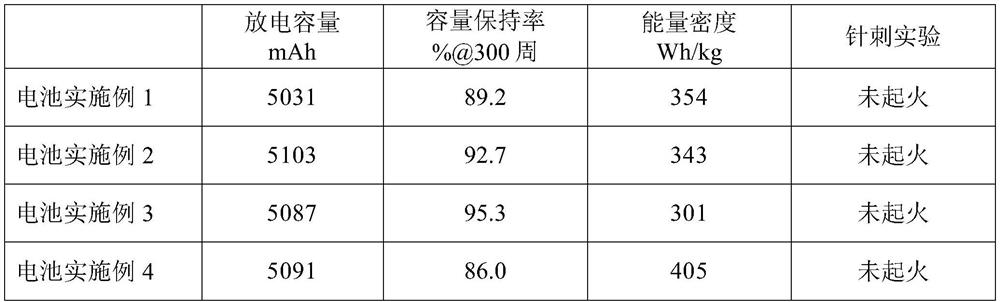

Examples

Embodiment 1

[0049] Preparation of positive pole piece: lithium cobaltate, polyvinylidene fluoride, Super-P, lithium bisfluorosulfonyl imide, 1,3-propenyl-sultone, acrylonitrile, diallyl maleate , azobisisobutyronitrile, Li1.3Al0.3Ti1.7(PO4)3 with a median particle diameter of 100nm, according to the weight ratio 96:2:2:1:1.6:0.2:1.6:0.16:6 to join the N -Stir and homogenize in methylpyrrolidone (NMP) to make a positive electrode slurry; apply the positive electrode slurry on both sides of the positive electrode current collector, bake at 85°C for 15 minutes to remove the solvent and initially polymerize, and then compact , slitting, 110°C, 4 hours of secondary baking, cutting, and welding tabs to obtain positive pole pieces.

[0050] Preparation of the negative electrode sheet: polyvinylidene fluoride, Super-P, lithium bisoxalate borate, ethylene carbonate, diallyl adipate, 1-hydroxycyclohexyl phenyl ketone, and a median particle size of 20nm Li0.34La0.56TiO3, according to weight ratio 1...

Embodiment 2

[0054] Preparation of positive electrode sheet: nickel cobalt lithium manganate, polyvinylidene fluoride, Super-P, lithium bisoxalate borate, 1,3-propenyl-sultone, diallyl carbonate, azobisisobutyl Nitrile and LiTi0.3Zr1.7(PO4)3 with a median particle size of 120nm are added to N-methylpyrrolidone (NMP) according to the weight ratio of 96:2:2:1:1.4:2.0:0.16:6 and stirred evenly The positive electrode slurry is made of positive electrode slurry; the positive electrode slurry is coated on both sides of the positive electrode current collector, and the solvent is removed after baking at 85°C for 15 minutes and initially polymerized, and then compacted, cut, and 110°C for 4 hours. The positive pole piece is obtained after secondary baking, cutting, and welding tabs.

[0055] Preparation of negative electrode sheet: sodium methylcellulose, SBR, Super-P, lithium bisoxalate borate, ethylene carbonate, isopentyl tetraacrylate, dimethyl azobisisobutyrate, median particles LiTi0.3Zr1.7...

Embodiment 3

[0059] Preparation of the positive electrode sheet: nickel cobalt lithium manganate, polyvinylidene fluoride, Super-P, lithium bisfluorosulfonyl imide, 1,3-propenyl-sultone, methyl methacrylate, maleic acid Diallyl acid, azobisisobutyronitrile, and Li0.5La0.5TiO3 with a median particle size of 70nm were added to N- Stir and homogenize in methylpyrrolidone (NMP) to make a positive electrode slurry; apply the positive electrode slurry on both sides of the positive electrode current collector, remove the solvent and preliminarily polymerize after baking at 85 ° C for 15 minutes, and then compact, After slitting, 110°C, 4 hours of secondary baking, cutting, and welding the tabs, the positive pole piece is obtained.

[0060] Preparation of negative electrode sheet: artificial graphite, sodium methylcellulose, SBR, Super-P, lithium bisoxalate borate, ethylene carbonate, isopentyl tetraacrylate, dimethyl azobisisobutyrate, The median particle diameter is Li0.5La0.5TiO3 of 40nm, acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com