Composite initiator of hydrophobic associated polymer and preparation method of hydrophobic associated polymer

A composite initiator and hydrophobic association technology, applied in the field of composite initiators, can solve problems such as increasing manufacturing costs and increasing electromagnetic radiation production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

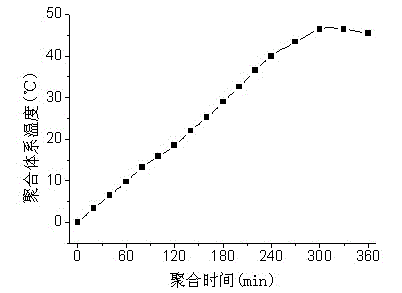

[0109] This composite initiator prepares the method for hydrophobic association polymer to carry out as follows:

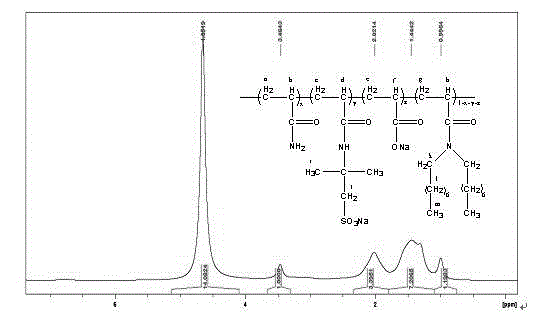

[0110] a. In the state of magnetic stirring, according to deionized water: sodium lauryl sulfate: acrylamide = 100:1:32 parts by weight and acrylamide: disodium edetate: sodium formate: AMPS‐Na: DiC8AM = 100:0.1:0.001:20:1 parts by weight, add disodium edetate, sodium formate, sodium lauryl sulfate, acrylamide, AMPS‐Na, DiC8AM into deionized water in sequence, and stir well , and then placed in a constant temperature water bath at 10°C;

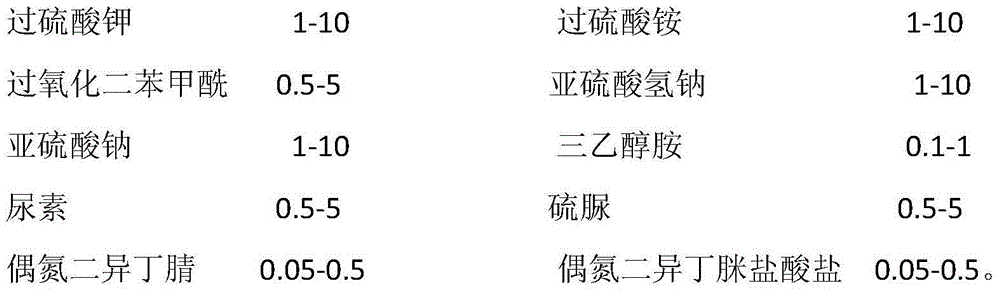

[0111] B. feed high-purity nitrogen into the mixed solution of a step for 60min, then add a composite initiator to polymerize for 4h to obtain a hydrophobically associated polymer colloid; the composite initiator is made from the following raw materials in proportions by weight:

[0112]

[0113] c. Coarsely crush the hydrophobically associated polymer colloid in step b, add 2.0% sodium hydroxide of the weight of the hydropho...

Embodiment 2

[0115] This composite initiator prepares the method for hydrophobic association polymer to carry out as follows:

[0116] a. In the state of magnetic stirring, according to deionized water: sodium lauryl sulfate: acrylamide = 100: 5: 22 parts by weight and acrylamide: disodium edetate: sodium formate: AMPS-Na: DiC8AM = 100: 0.01: 0.01: 5: 10 parts by weight, sequentially add disodium edetate, sodium formate, sodium lauryl sulfate, acrylamide, AMPS-Na, DiC8AM into deionized water, and stir well , and then placed in a constant temperature water bath at 20°C;

[0117] B. feed high-purity nitrogen into the mixed solution of step a for 30min, then add composite initiator to polymerize for 8h to obtain hydrophobic association polymer colloid; described composite initiator is made from the raw materials of following weight portion proportioning:

[0118]

[0119] c. After coarsely crushing the hydrophobically associated polymer colloid in step b, add 3.5% of the weight of the hyd...

Embodiment 3

[0121] This composite initiator prepares the method for hydrophobic association polymer to carry out as follows:

[0122]a. In the state of magnetic stirring, according to deionized water: sodium lauryl sulfate: acrylamide = 100: 2: 25 parts by weight and acrylamide: disodium edetate: sodium formate: AMPS-Na: DiC8AM = 100:0.05:0.003:15:5 parts by weight, sequentially add disodium edetate, sodium formate, sodium lauryl sulfate, acrylamide, AMPS-Na, DiC8AM into deionized water, and stir well , and then placed in a constant temperature water bath at 15°C;

[0123] B. feed high-purity nitrogen into the mixed solution of a step for 45min, then add composite initiator to polymerize for 6h, to obtain hydrophobic association polymer colloid; described composite initiator is made from the raw materials of following weight portion proportioning:

[0124]

[0125] c. Coarsely crush the hydrophobically associated polymer colloid in step b, add 3.0% of the weight of the hydrophobically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com