Manufacturing method of continuous long fiber reinforced reaction type resin

A technology to enhance the reaction and manufacturing method, which is applied in the field of resin manufacturing, can solve the problems of application limitations, difficult to manufacture materials, etc., and achieve the effects of good adhesion, fast polymerization speed, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

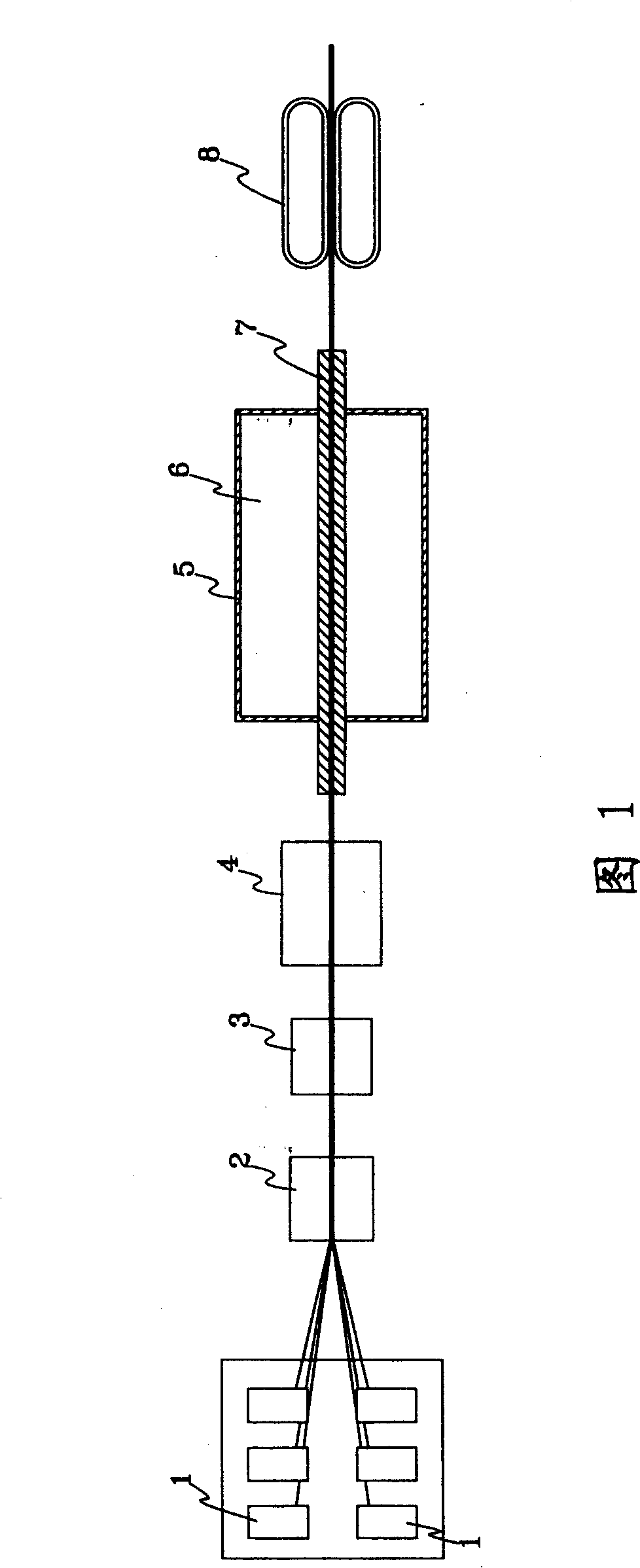

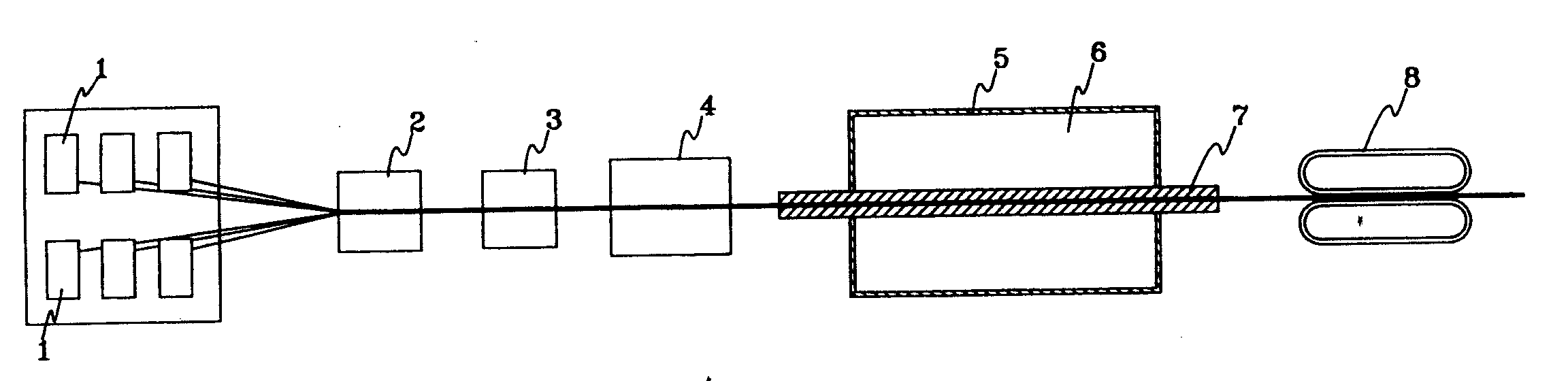

Image

Examples

Embodiment 1

[0034]Dissolve 20 parts of heavy polymethyl methacrylate (organic glass) in 80 parts of heavy methyl methacrylate monomer under heating, add 1 part of heavy azobisisobutylcyanide (AIBN), dissolve as Dipping solution. Immerse the low-alkali untwisted glass fiber in 10% ethyltrimethoxysilane acetone solution, then dry it, impregnate it through the impregnation chamber, enter the mold under the traction of the tractor, and adjust the power of the microwave heater to 500W , to obtain rod-shaped continuous fiber-reinforced polymethyl methacrylate with a diameter of 2 mm.

Embodiment 2

[0036] Dissolve 25 parts by weight of high impact styrene (HIPS) in 75 parts by weight of methyl methacrylate and isooctyl methacrylate mixed monomer under heating, add 5 parts by weight of dipropylene terephthalate The ester is dissolved, and then 1.5% by weight of the monomer tert-butyl peroxyisooctanoate (TBPO) is added to dissolve as an impregnating solution. Immerse the low-alkali untwisted glass fiber in 10% vinyltrimethoxysilane (A-151) acetone solution, then dry it, impregnate it through the impregnation chamber, enter the mold under the traction of the tractor, and adjust the microwave heating The power of the device was 500W, and a rod-shaped continuous fiber-reinforced cross-linked high-impact composite material with a diameter of 2mm was obtained.

Embodiment 3

[0038] 100 parts by weight of propylene glycol diacrylate is dissolved with 1 part by weight of azobisisobutylcyanide (AIBN) as an impregnation solution, and the glass fiber treated with silane coupling agent-methacryloxypropyltrimethoxysilane on the surface is impregnated , Through the pultrusion machine, under the microwave heater 600W, the glass fiber reinforced thermosetting composite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com