Molding method of continuous fiber reinforced thermoplastic resin sheet

A technology for reinforcing thermoplastic and thermoplastic resin, which is applied in the field of continuous fiber reinforced thermoplastic resin sheet molding, can solve the problems of single dipping equipment, reduced dipping effect and high polymer melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

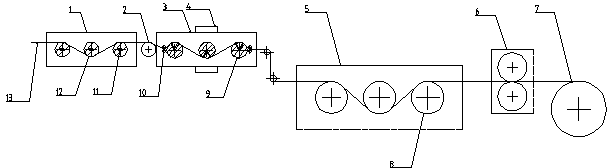

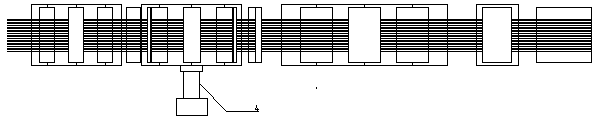

[0025] Install the continuous carbon fiber T300 (manufactured by Toray Corporation, Japan) on the spindle of the creel, then wind the carbon fiber in a wave pattern and pass through the pre-dispersion device, while heating the carbon fiber at a preset temperature of 260°C; Eliminate static electricity due to friction, and then lead the carbon fiber to the wire inlet hole of the radiation melting impregnation device, and the carbon fiber entering the radiation melting impregnation device is also wound around the first tension roller in a wave pattern, and the carbon fiber is led to the second impregnation in the same way Finally, the carbon fiber is led out from the outlet of the secondary impregnation device, and then passes through the traction device and the winding device in turn.

[0026] After the arrangement of carbon fibers is completed, the twin-screw extruder is turned on, and the thermoplastic resin melt is pressed into the radiation melting impregnation mold. The set...

specific Embodiment 2

[0028] The continuous glass fiber (Zhejiang Jushi Group) is installed on the spindle of the creel, and then the glass fiber is wound through the pre-dispersion device according to the wave shape, and the glass fiber is heated at the same time, the preset temperature is 230 ℃; after that, it is passed through the static elimination device Eliminate the static electricity caused by friction, and then guide the glass fiber to the wire inlet hole of the radiation melting and impregnation device, and the glass fiber entering the radiation melting and impregnation device is also wound around the tension roller in a wave pattern, and the glass fiber is guided to the secondary in the same way. The impregnating device finally guides the glass fiber from the outlet of the secondary impregnating device, and passes through the traction device and the winding device in turn.

[0029] After the arrangement of the glass fibers is completed, the twin-screw extruder is turned on, and the thermo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com