Homogeneous anion exchange membrane and preparation method thereof

An anion-exchange membrane and coating technology, applied in the field of homogeneous anion-exchange membranes and their preparation, can solve the problems of wasting trimethylamine aqueous solution, increasing costs, and reducing the electrochemical performance of anion-exchange membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention discloses a method for preparing a homogeneous anion exchange membrane. The method comprises the following steps:

[0037] Dissolving the halomethylated aromatic polymer in an organic solvent to form a solution to be reacted;

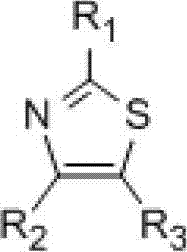

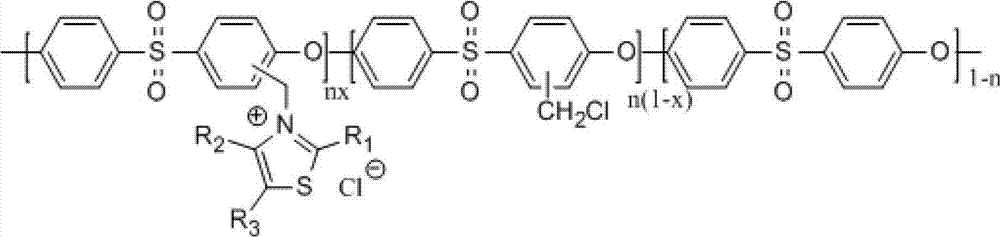

[0038] mixing the solution to be reacted with thiazole functional small molecules and performing a nucleophilic substitution reaction to obtain a casting solution of an aromatic polymer with positively charged thiazole functional small molecule side groups; and

[0039] The casting solution is coated on a substrate and dried, after which the substrate is removed, or the casting solution is coated on a reinforcing fabric and dried to obtain a homogeneous anion exchange membrane.

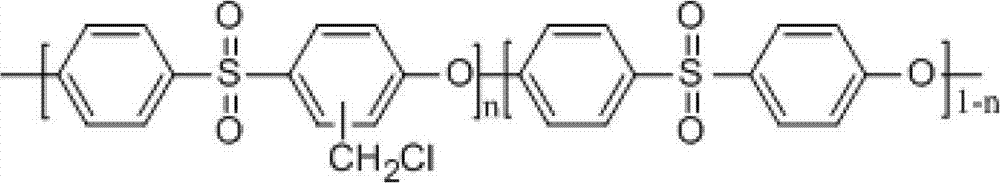

[0040]The halomethylated aromatic high polymer is halomethylated polyphenylsulfone, polyethersulfone, bisphenol A polysulfone, polyether ether ketone, polyether ketone, polyphenylene ether, polynaphthyl biphenyl Ether sulfone, polynaphthalene polyether sul...

Embodiment 1

[0063] 1g of polyethersulfone (halomethyl 0.75mmol) with a degree of halomethylation of 18mol% is dissolved in 10ml of toluene to form a solution to be reacted with a mass volume concentration of 10m / v%. After adding 0.074g of 2-methylthiazole ( 0.75mmol, 1 equivalent), stirred and reacted at 25°C for 24h to obtain a casting solution. The casting solution is cast on a polytetrafluoroethylene plate, heated and dried at 60°C to obtain an anion exchange membrane.

[0064] The prepared anion exchange membrane has uniform and transparent appearance, good mechanical strength and high flexibility of the membrane. Test its related properties: water content 10%, ion exchange capacity 0.65mmolg -1 , with an ionic conductance of 8mS cm -1 , The mechanical strength is 25MPa.

Embodiment 2

[0066] Similar to Example 1, except that the casting solution was scraped on the polyethylene film, heated and dried at 100°C to obtain an anion exchange membrane.

[0067] Since the composition of the membrane liquid is the same, the properties of the anion exchange membrane prepared in this example are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com