Pavement paving structure for melting snow and ice and using method thereof

A pavement and bonding technology, which is applied in the direction of on-site paved condensate pavement, roads, roads, etc., can solve the problems that cannot be used on existing roads, achieve good electrical conductivity, reduce heat loss and loss, and have wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

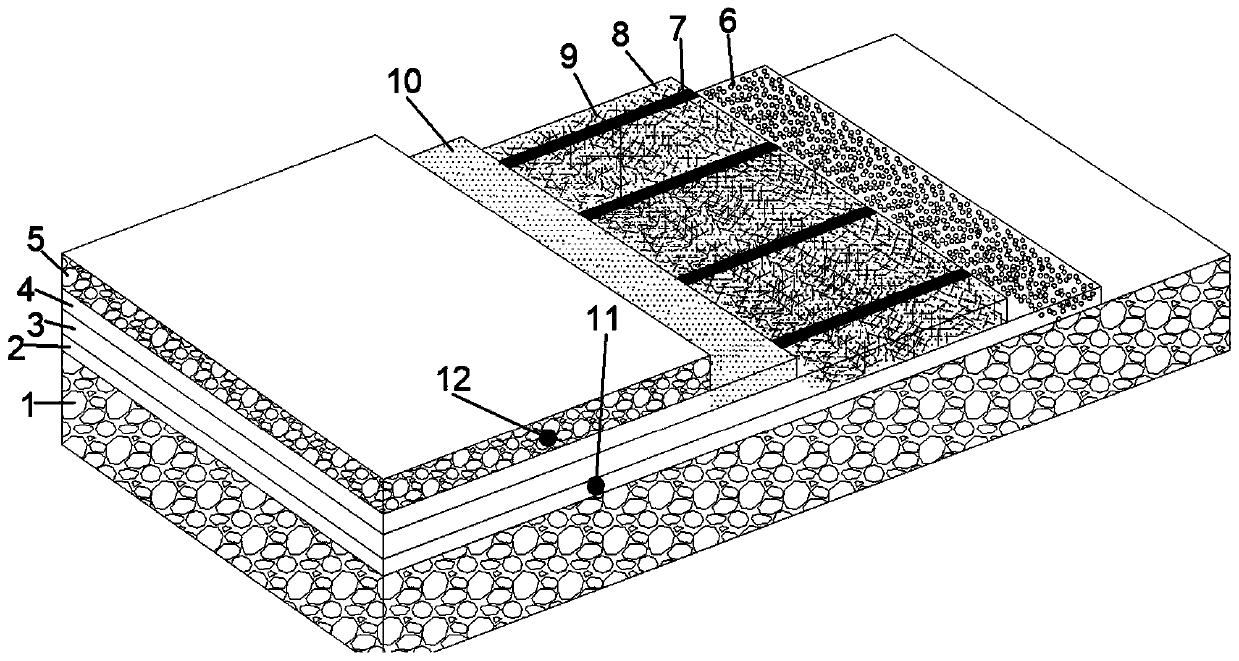

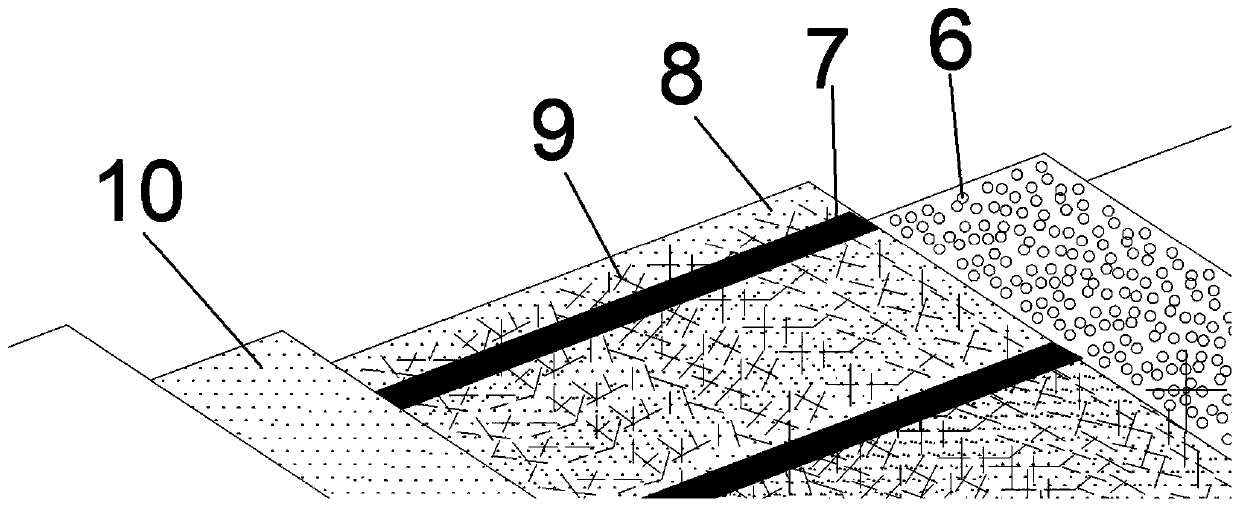

[0032] refer to figure 1 , the invention discloses a road pavement structure for melting snow and ice, comprising a heat insulation layer 2, a conductive adhesive layer 3, a waterproof adhesive heat conduction layer 4 and a wear layer 5, which are sequentially arranged on a lower bearing layer 1 from bottom to top ; Wherein the thermal insulation layer 2 is added with thermal insulation filler 6, the conductive adhesive layer 3 is added with powder conductive filler 8 and carbon fiber 9, and at the same time, conductive electrodes 7 are arranged in the conductive adhesive layer 3, and the waterproof adhesive thermal conduction layer 4 is added There are thermally conductive fillers 10, and the underlying layer 1 is the old asphalt concrete pavement;

[0033]The insulation layer 2 is made of water-based epoxy modified emulsified asphalt and hollow glass microspheres, and the spreading amount of the insulation layer 2 is 0.4kg / m 2 , wherein 22 parts of hollow glass microspheres...

Embodiment 2

[0039] Except the following content, other content is all the same as embodiment 1.

[0040] The insulation layer 2 is prepared by mixing 80 parts of water-based polyurethane epoxy modified emulsified asphalt and 20 parts of hollow glass microspheres, and the spreading amount is 0.4kg / m 2 ; The conductive bonding layer 3 is prepared by mixing 89 parts of water-based polyurethane epoxy modified emulsified pitch, 5 parts of graphite and 6 parts of carbon fiber, and the spreading amount is 0.5 kg / m 2 ; The waterproof bonding and heat-conducting layer 4 is prepared by mixing 95 parts of water-based polyurethane epoxy modified emulsified asphalt and 5 parts of graphite, and the spreading amount is 0.4kg / m 2 ; Carbon fiber length is 8mm.

Embodiment 3

[0042] Except the following content, other content is all the same as embodiment 1.

[0043] Heat insulation layer 2 is prepared by mixing 82 parts of water-based epoxy resin and 18 parts of diatomaceous earth, and the spreading amount is 0.3kg / m 2 ; The conductive adhesive layer 3 is prepared by mixing 93 parts of water-based acrylic resin, 3 parts of carbon nanotubes and 4 parts of carbon fiber, and the spreading amount is 0.6kg / m 2 ; The waterproof bonding heat-conducting layer 4 is prepared by mixing 95 parts of water-based epoxy resin and 5 parts of carbon nanotubes, and the spreading amount is 0.3kg / m 2 ; Carbon fiber length is 6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com