Ultra-thin wearing layer asphalt mixture and preparation method thereof

A technology of asphalt mixture and wear layer, which is used in building thermal insulation materials, building components, building structures, etc., to achieve the effects of improving high temperature stability, improving safety, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

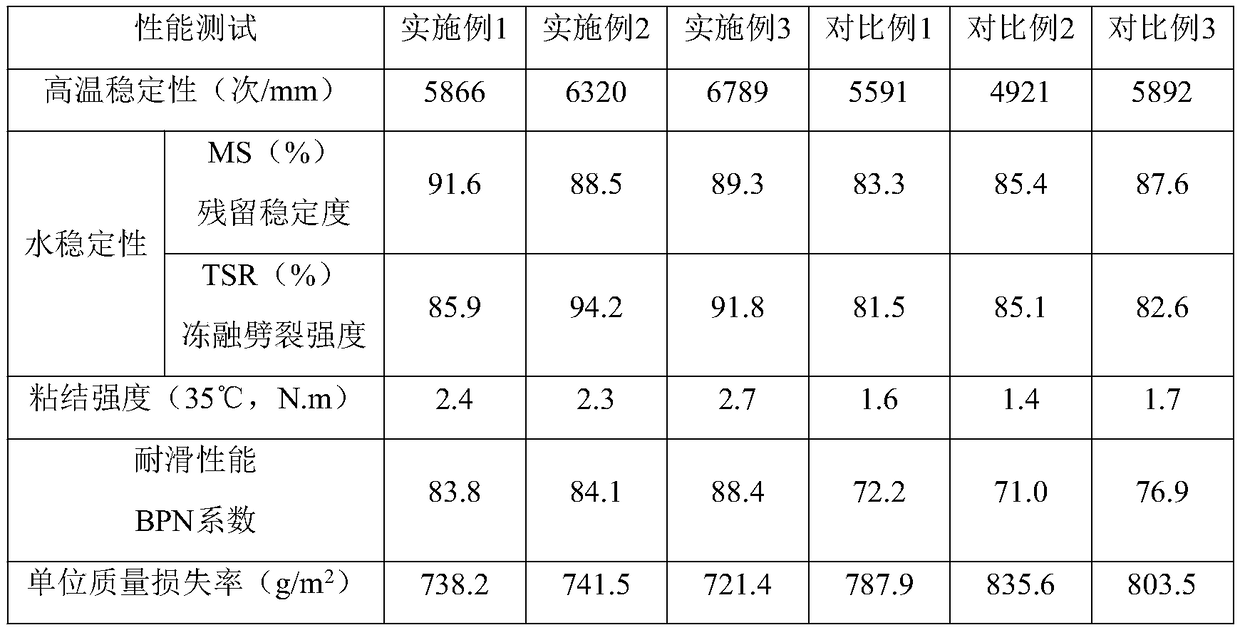

Examples

preparation example 1

[0030] Mix 20Kg of methyl methacrylate, 10Kg of brominated epoxy resin, 5Kg of nano-carbon powder, and 5Kg of sodium silicate at 120°C and add them to 20Kg of rubber oil. After stirring and heating to 150°C, the pressure is 2.0Mpa Under the condition of keeping warm for 2 hours, the binding agent is obtained.

preparation example 2

[0032] Mix 40Kg of methyl methacrylate, 15Kg of brominated epoxy resin, 8Kg of nano-carbon powder, and 8Kg of sodium silicate at 125°C and add them to 35Kg of rubber oil. After stirring and heating to 155°C, the pressure is 2.25Mpa Under the condition of keeping warm for 3 hours, the binding agent is obtained.

preparation example 3

[0034]Mix 60Kg of methyl methacrylate, 20Kg of brominated epoxy resin, 10Kg of nano-carbon powder, and 10Kg of sodium silicate at 130°C and add them to 50Kg of rubber oil. After stirring and heating to 160°C, the pressure is 2.5Mpa Under the condition of keeping warm for 4 hours, the binding agent is obtained.

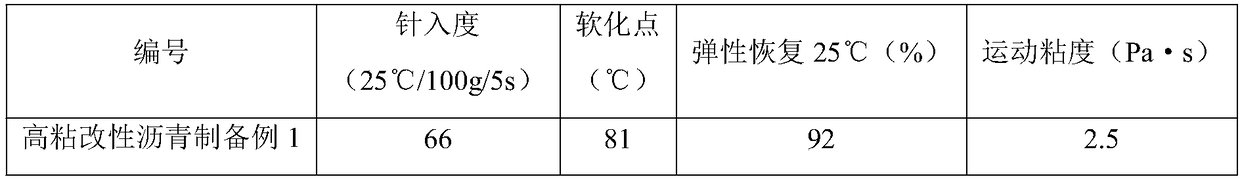

[0035] Preparation Example 1 of High Viscosity Modified Asphalt

[0036] Heat 100Kg of base asphalt to 175°C, add 15Kg of styrene-isoprene-styrene block copolymer and 10Kg of polybutylene-terephthalate-polyether glycol block polymer, and heat at 175°C Swell at 190°C for 0.5 hours, then heat up to 185°C, then add 3Kg of binder and 0.05Kg of sulfur powder provided by the binder preparation example 1, control the temperature at 190°C and stir for 3 hours, then add 3Kg of sulfur powder after lowering the temperature to 180°C Phenyl dipropylene glycol diphosphite, that is, high-viscosity modified asphalt.

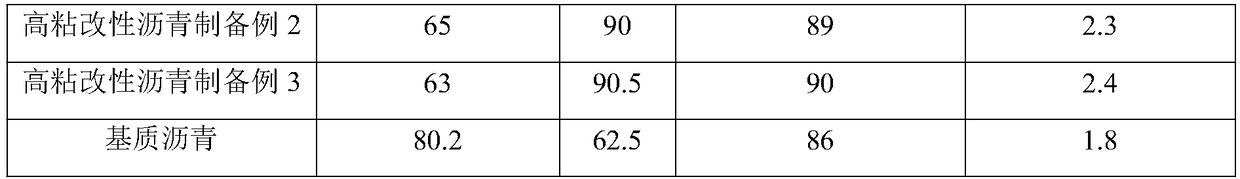

[0037] Preparation Example 2 of High Viscosity Modified Asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com