Asphalt concrete for ultra-thin wearing course with easily-compactable skeleton and thickness of 1 to 1.5 cm

An asphalt concrete and wear layer technology, which is applied to the coagulation pavement, building components, climate change adaptation and other directions of on-site paving, can solve the problems of high road maintenance costs, difficult to guarantee compaction, and difficult construction control, etc. Achieve the effects of excellent crack resistance, improved fatigue life and excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0057] The advantages of the present invention will be described below for the mix ratio test and verification of 1-1.5cm asphalt single-layer pavement construction with median gradation and different asphalt ratios.

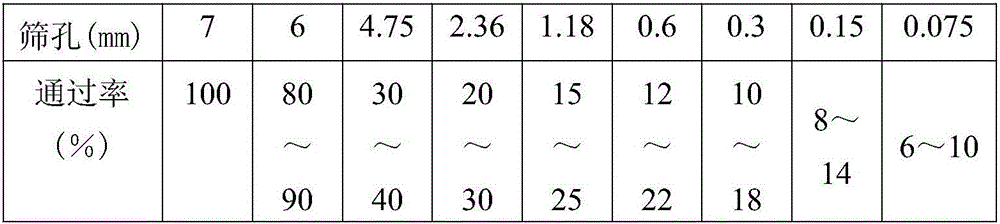

[0058] Table 5 Mixture Median Graded Material Composition Ratio

[0059] material ratio

5-7mm

0-3mm

mineral powder

Oil-stone ratio

median grading

70

22

6

2

5.8-6.2

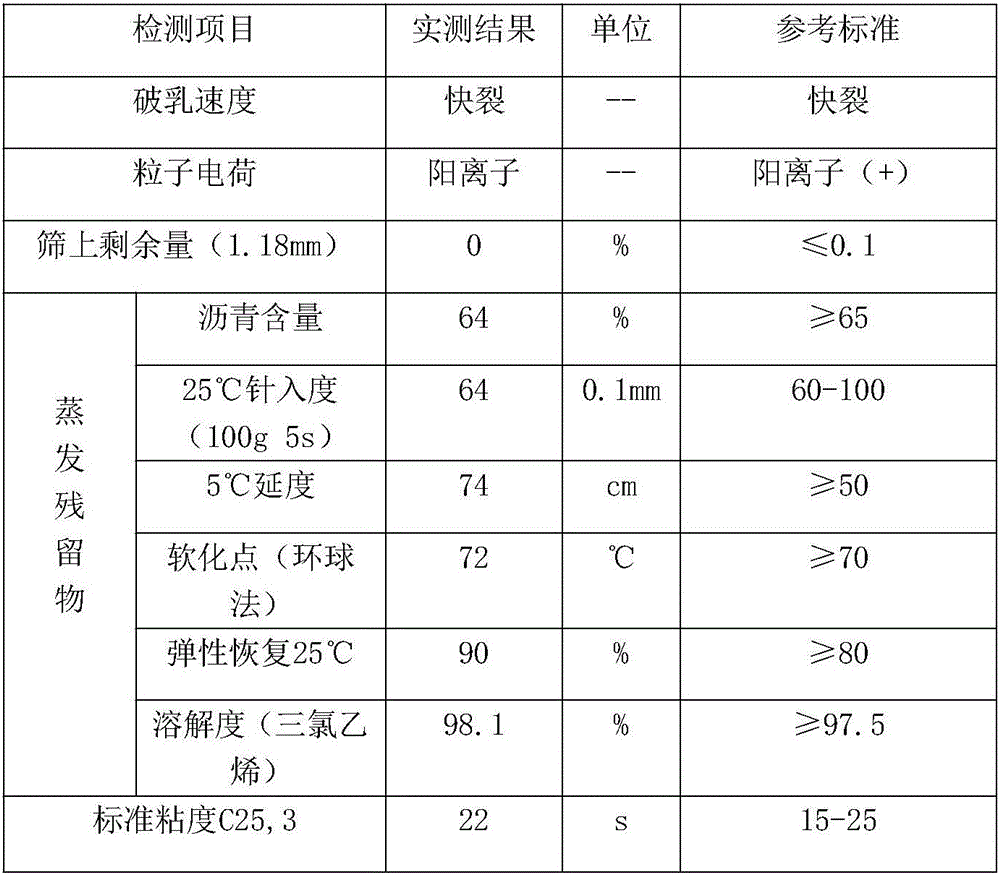

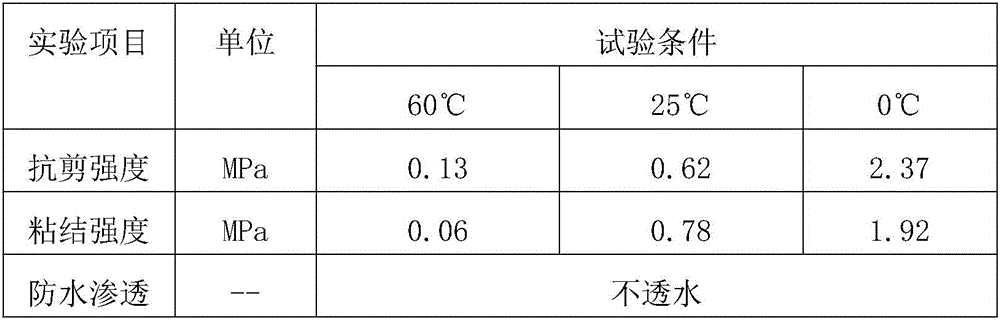

[0060] Table 6 mixture test results

[0061]

Embodiment 7~9

[0063] Table 7 Embodiment proportioning (%) of the ultra-thin asphalt pavement surface layer mixture of 1-1.5cm of the present invention

[0064] Example

[0065] The asphalt mixture can be produced according to the formula in Table 7. The aggregates and fillers are heated separately, put into the mixing pot by metering, dry mix for 5 seconds, add high-elastic modified asphalt (or warm-mix high-elastic modified asphalt), and mix for 40 seconds, that is It can produce finished asphalt mixture, which can pave 1-1.5cm ultra-thin asphalt pavement, and can achieve good technical and economic effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com