SBS (styrene butadiene styrene)/SBR (styrene butadiene rubber) composite modified emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and compound modification, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of high Engler's viscosity and low solid content, and achieve the effect of low viscosity, high solid content and high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

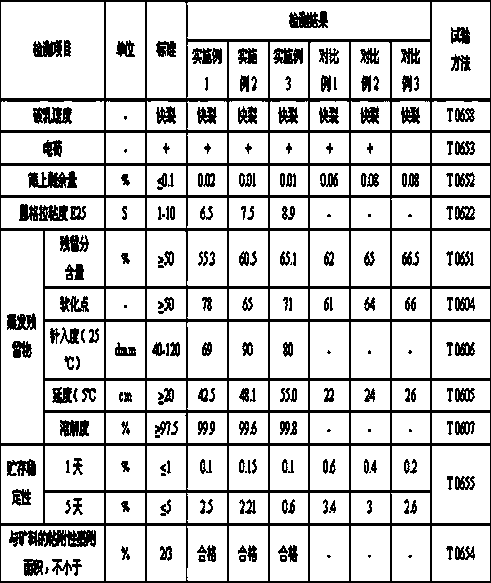

Examples

preparation example Construction

[0018] A kind of SBS / SBR composite modified emulsified asphalt of the present invention is made up of base asphalt, linear SBS, SBR latex, compatibilizer, stabilizer, viscosity reducer, emulsifier, hydrochloric acid and water, and the quality of described linear SBS is The mass of base asphalt is 3.5%~5.5%, the mass of compatibilizer is 1%~4% of the mass of base asphalt, the mass of stabilizer is 0.1%~0.4% of the mass of base asphalt, and the mass of viscosity reducer is 2.0% of the mass of base asphalt ~10.0%, the emulsifier quality is 0.5%~1.5% of the base asphalt quality, the SBR latex quality is 1%~5% of the base asphalt quality, the preparation method of the SBS / SBR composite modified emulsified asphalt comprises the following steps:

[0019] (1) Preparation of SBS modified asphalt: heat base asphalt to 180°C~190°C, add linear SBS, compatibilizer and stabilizer to base asphalt at the same time, and use high-speed shearing machine to shear and disperse for 60min~200min, Ma...

Embodiment 1

[0026] The component ratio of SBS / SBR composite modified emulsified asphalt is:

[0027] No. 70 heavy traffic asphalt 800g Compatibilizer 12g SBS 35g stabilizer 2.3g Emulsifier 6g Water (PH=2) 710g Viscosity reducer 32g SBR latex 30g

[0028] According to the above component distribution ratio, the following steps are used to prepare SBS / SBR composite modified emulsified asphalt:

[0029] (1) Heat the base asphalt to 185°C, add linear SBS, compatibilizer and stabilizer to the base asphalt at the same time, and use high-speed shearing machine to shear and disperse for 120 minutes to make SBS modified asphalt;

[0030] (2) Add emulsifier and hydrochloric acid into hot water at 70°C, adjust the pH value to 2, and make soap liquid;

[0031] (3) Keep the modified asphalt prepared in (1) at constant temperature to 138°C, add the modified asphalt, viscosity reducer and the soap solution prepared in step (2) to the colloid mill ...

Embodiment 2

[0034] The component ratio of SBS / SBR composite modified emulsified asphalt is:

[0035] No. 70 heavy traffic asphalt 800g Compatibilizer 24g SBS 36g stabilizer 2g Emulsifier 7g Water (PH=2) 580g Viscosity reducer 48g SBR latex 12g

[0036] According to the above component distribution ratio, the following steps are used to prepare SBS / SBR composite modified emulsified asphalt:

[0037](1) Heat the base asphalt to 185°C, add linear SBS, compatibilizer and stabilizer to the base asphalt at the same time, and use high-speed shearing machine to shear and disperse for 90 minutes to make SBS modified asphalt;

[0038] (2) Add emulsifier and hydrochloric acid into hot water at 65°C, adjust the pH value to 2, and make soap liquid;

[0039] (3) Keep the modified asphalt prepared in (1) at constant temperature to 130°C, add the modified asphalt, viscosity reducer and the soap solution prepared in step (2) to the colloid mill at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com