Paving structure of heavy-duty traffic road based on high stiffness modulus asphalt mixture

A technology of asphalt mixture and road pavement, which is applied in the direction of roads, roads, and on-site coagulation pavement, etc. Reduce the anti-fatigue performance of materials and other problems, and achieve the effect of improving high temperature anti-rutting effect, good overall use effect and low paving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

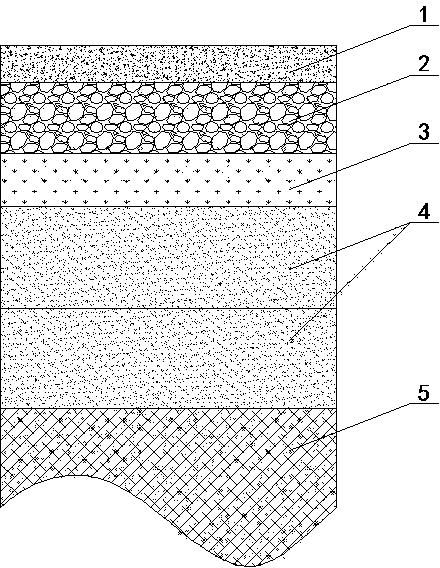

[0045] In the present invention, an anti-wear layer 1, an anti-rutting deformation layer 2, an anti-fatigue layer 3 and a semi-rigid base layer 4 constitute a complete heavy-duty traffic road pavement structure. The anti-wear layer 1, the anti-rutting deformation layer 2, the anti-fatigue layer 3, and the semi-rigid base layer 4 are laid on the subgrade 5 from top to bottom.

[0046]The anti-wear layer 1 adopts a broken gradation structure, the nominal particle size of the mixture is 9.5mm, the porosity is 3.5%-4%, and the thickness is 3-4cm. The gradation range of the asphalt mixture for the anti-skid wear layer is calculated based on the percentage of mineral materials of each particle size passing through the standard size sieve hole:

[0047] 9.5mm, 90%~100%; 4.75mm, 28%~60%; 2.36mm, 20%~32%; 1.18mm, 14%~26%; 0.6mm, 12%~22%; 0.3mm, 10% -18%; 0.15mm, 9%-16%; 0.075mm, 8%~13%.

[0048]

[0049] The anti-rutting deformation layer 2 adopts a dense and graded skeleton struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com