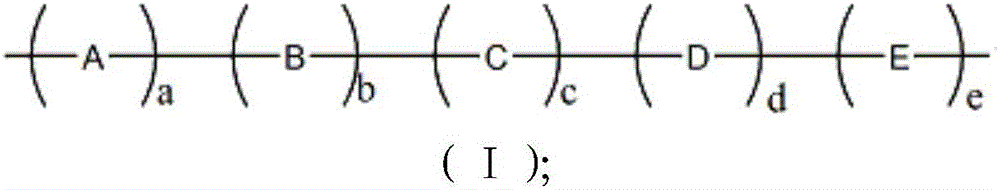

Surface tension adjustment reduction type polycarboxylate superplasticizer and preparation method thereof

A technology of surface tension and polycarboxylic acid, which is applied in the field of shrinkage reducing agent, can solve the problems of cement adaptability, delayed ettringite formation, inability to reduce concrete shrinkage, and difficulty in adjusting its addition amount, achieving high cost performance, simple method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

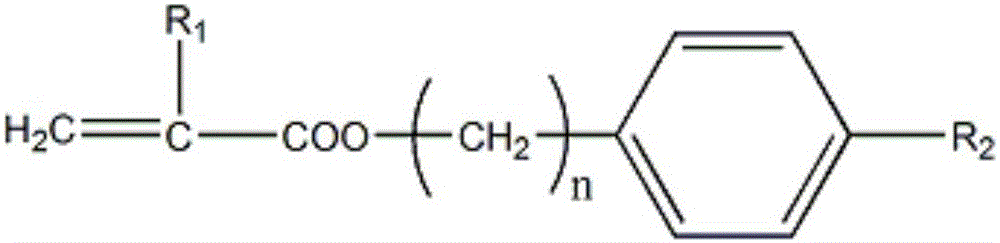

Method used

Image

Examples

Embodiment 1

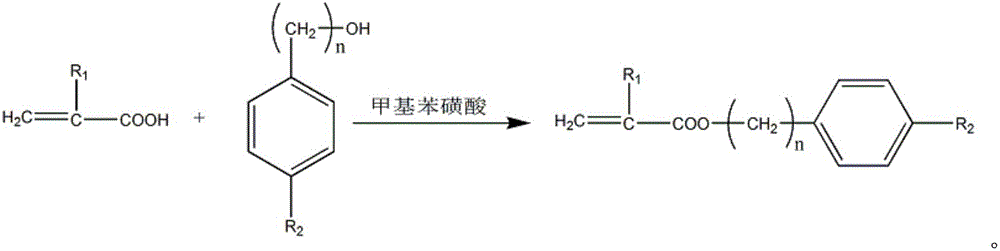

[0046] An embodiment of the surface tension-adjusting shrinkage-reducing polycarboxylate water-reducer of the present invention, the preparation method of the surface tension-adjusting shrinkage-reducing polycarboxylate water-reducer is as follows:

[0047] (1) In a 500ml four-neck glass flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.5mol methacrylic acid, 0.5mol benzyl alcohol, toluenesulfonic acid (the amount is methacrylic acid and benzyl alcohol 2% of the total weight), 4-methoxyphenol (the amount is 0.2% of the total weight of methacrylic acid and benzyl alcohol), stirred, heated up to 80 ° C, kept for 6 hours, and cooled to obtain the reaction product benzyl methacrylate base ester.

[0048] (2) Add 1200ml of water, methacrylic acid, APEG, allyl polyoxypropylene ether, sodium allylbenzenesulfonate, mercaptoethanol, The benzyl methacrylate that step (1) obtains, the mol ratio of the reaction product that described methacrylic acid, APEG, ally...

Embodiment 2

[0050] An embodiment of the surface tension-adjusting shrinkage-reducing polycarboxylate water-reducer of the present invention, the preparation method of the surface tension-adjusting shrinkage-reducing polycarboxylate water-reducer is as follows:

[0051] (1) In a 500ml four-neck glass flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.6mol acrylic acid, 0.5mol methyl benzyl alcohol, toluenesulfonic acid (the amount is methacrylic acid and benzyl alcohol 2.5% of the total weight), methoxyhydroquinone (the amount is 0.3% of the total weight of methacrylic acid and benzyl alcohol), stirred, heated up to 90 ° C, kept for 5 hours, and cooled to obtain the reaction product methyl benzyl acrylate ester.

[0052] (2) Add 1200ml of water, acrylic acid, HPEG, allyl polyoxypropylene ether, sodium allylbenzenesulfonate, mercaptoacetic acid, step ( 1) the methyl benzyl acrylate obtained, the mol ratio of the reaction product that described acrylic acid, HPEG, a...

Embodiment 3

[0054] An embodiment of the surface tension-adjusting shrinkage-reducing polycarboxylate water-reducer of the present invention, the preparation method of the surface tension-adjusting shrinkage-reducing polycarboxylate water-reducer is as follows:

[0055] (1) In a 500ml four-neck glass flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.6mol methacrylic acid, 0.5mol phenylethyl alcohol, toluenesulfonic acid (the amount is the total amount of methacrylic acid and benzyl alcohol) 2% by weight), 4-methoxyphenol (consumption is 0.2% of the total weight of methacrylic acid and benzyl alcohol), stirred, heated up to 85 ° C, kept for 6 hours, and cooled to obtain the reaction product phenylethyl methacrylate ester.

[0056] (2) Add 1200ml of water, methacrylic acid, VPEG, allyl polyoxypropylene ether, sodium allylbenzenesulfonate, and mercaptopropanol into a 2000ml four-necked glass flask equipped with a stirrer, a thermometer, and a reflux condenser , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com