Lightweight wall special-purpose cell concrete, and production method thereof

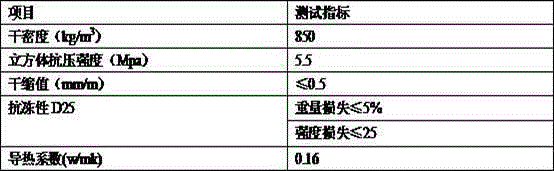

A technology for concrete and wall materials, which is applied to the special microporous concrete for lightweight wall materials and its production field, can solve the problems of uncontrollable production process, heavy concrete weight, large drying shrinkage and easy cracking, etc., so as to reduce shrinkage cracking phenomenon and improve Thermal properties, the effect of enhancing product performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A special microporous concrete production method for lightweight wall materials is:

[0019] (1) Add 320kg of fast-hardening sulfoaluminate cement, 80kg of ordinary Portland cement, and 300kg of dry-discharge fly ash into a double-helix conical mixer to pre-mix to form a composite cement;

[0020] (2) 4kg cold water soluble polyvinyl alcohol powder, 2kg polypropylene reinforcing fiber, 4kg calcium stearate water repellent, 0.3kg silane coupling agent, 10kg expanded perlite, 5kg polystyrene foam particles are added in the mixer;

[0021] (3) Add the composite cement prepared in step (1) into the mixer, the water-material ratio is 0.60~0.75, and spray the microcellular foam prepared by the microcellular foam agent with compressed air into the mixer, mix and stir to form a uniform slurry, And control the density of slurry to 1000~1200kg / m 3 ;

[0022] (4) Pump uniform slurry into light wall material products or cast-in-place wall forming molds;

[0023] (5) Release the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com