Shrinkage reducing and curing agent for concrete

A curing agent and concrete technology, applied in the field of concrete additives, can solve the problems of compatibility between water reducing agent and shrinkage reducing agent, affecting the popularization and application, and high price of shrinkage reducing agent, and achieves reduction of shrinkage cracks, convenient use and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

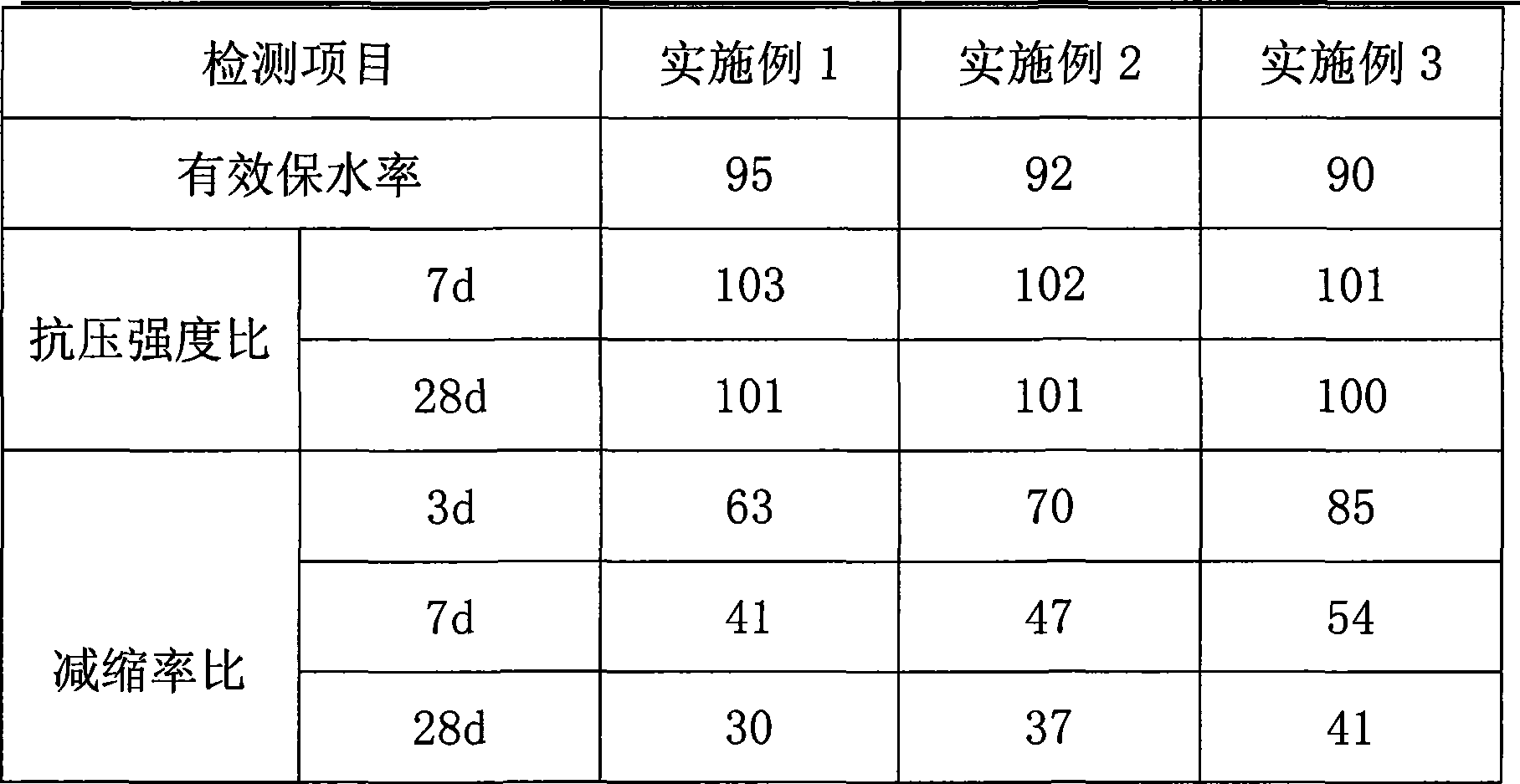

Examples

Embodiment 1

[0015] Concrete shrinkage curing agent, the formula of this curing is (percentage by weight)

[0016]

[0017] Polymer film formation

Embodiment 2

[0019] JK-SRA shrinkage curing agent, the formula of this curing is (percentage by weight);

[0020]

[0021] penetrant polyethylene glycol 3 Number average molecular weight 1000

Embodiment 3

[0023] JK-SRA shrinkage curing agent, the formula of this curing is (percentage by weight);

[0024] Main points raw material percentage technical indicators filler water 72 tap water

Shrinkage reducer

Methacrylic

Acid methyl ester;

polyethylene glycol

monomethyl ether propylene

20

Methyl methacrylate: Polyethylene glycol

Alcohol monomethyl ether acrylate = 2:

3. Polyethylene glycol monomethyl ether acrylic acid

The number average molecular weight of the ester is 1500, minus

The number average molecular weight of shrinkage agent is 50000 High water soluble organic

Molecular film former

3

The number average molecular weight is 1500

Inorganic Densifying Materials water glass 2 Water glass modulus 1.0 penetrant polyethylene glycol 3 Number average molecular weight 200

[0025] Apply the concrete shrinkag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com