Special fine sand hydraulic large volume normal-state concrete

A technology for concrete and ultra-fine sand is applied in the field of hydraulic construction concrete, which can solve the problem that the resource reserve of coarse and medium sand cannot meet the construction scale, and achieve the effect of reducing dry shrinkage value and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

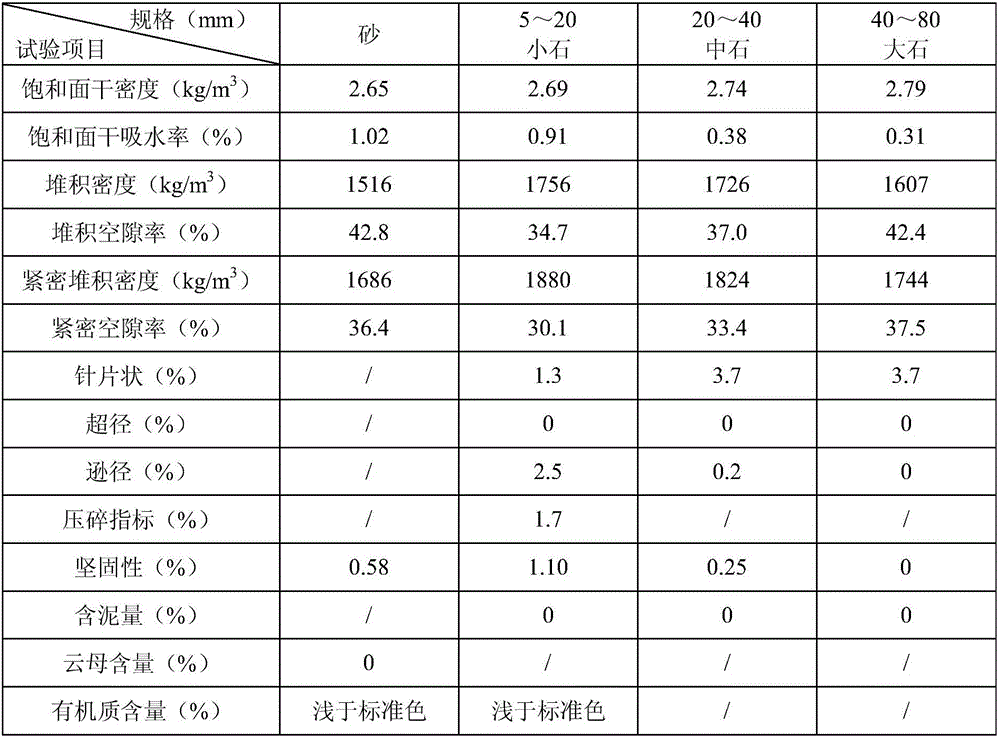

[0013] 1. Sand aggregate

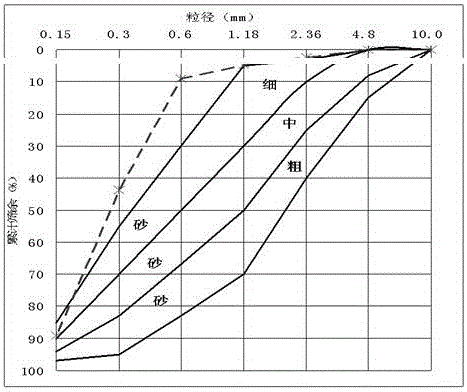

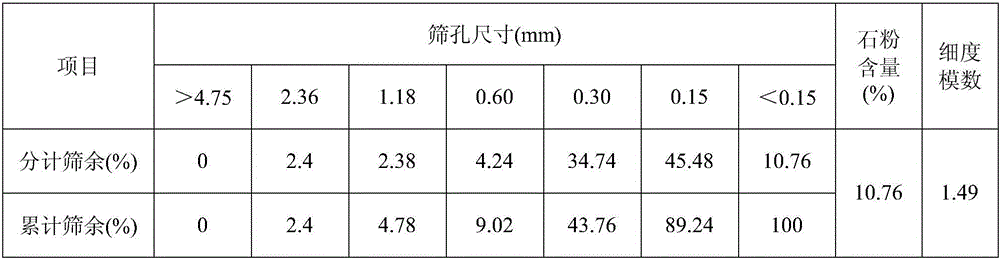

[0014] In concrete, sand and gravel aggregates generally account for 80% to 85% of the total mass of concrete, and its quality has a significant impact on the physical and mechanical properties of concrete; "Construction Sand GB / T14684-2011" 4.2 "Specifications" stipulates: According to the fineness modulus, the sand is divided into three specifications: coarse, medium and fine. The fineness modulus is respectively: coarse sand—3.7~3.1; When the number is less than 1.6, it is unanimously named as ultra-fine sand in the industry. The sand and gravel aggregate used in this test is the natural river sand aggregate from the stockyard at the gate site of the Longxikou Navigation Power Project in Minjiang, Sichuan, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com