3D printed solid waste concrete member and preparation method

A 3D printing, waste concrete technology, applied in the field of concrete, can solve the problems of low shrinkage, 3D printing components cannot be embedded with steel bars, etc., to achieve the effect of reducing density, adjustable setting time, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

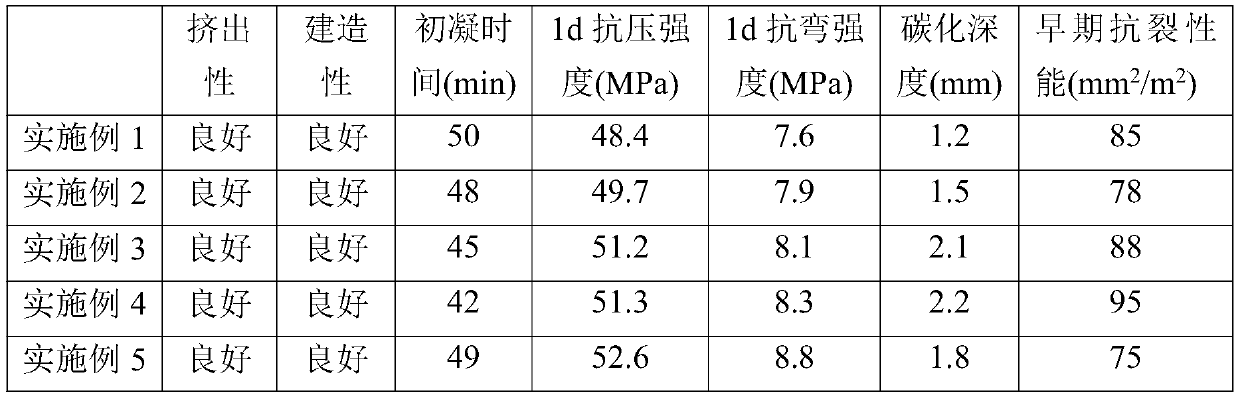

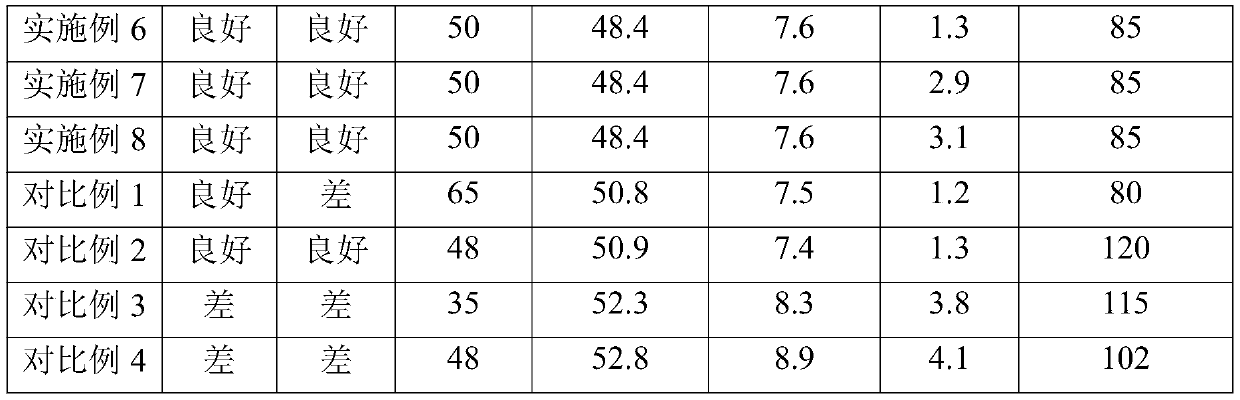

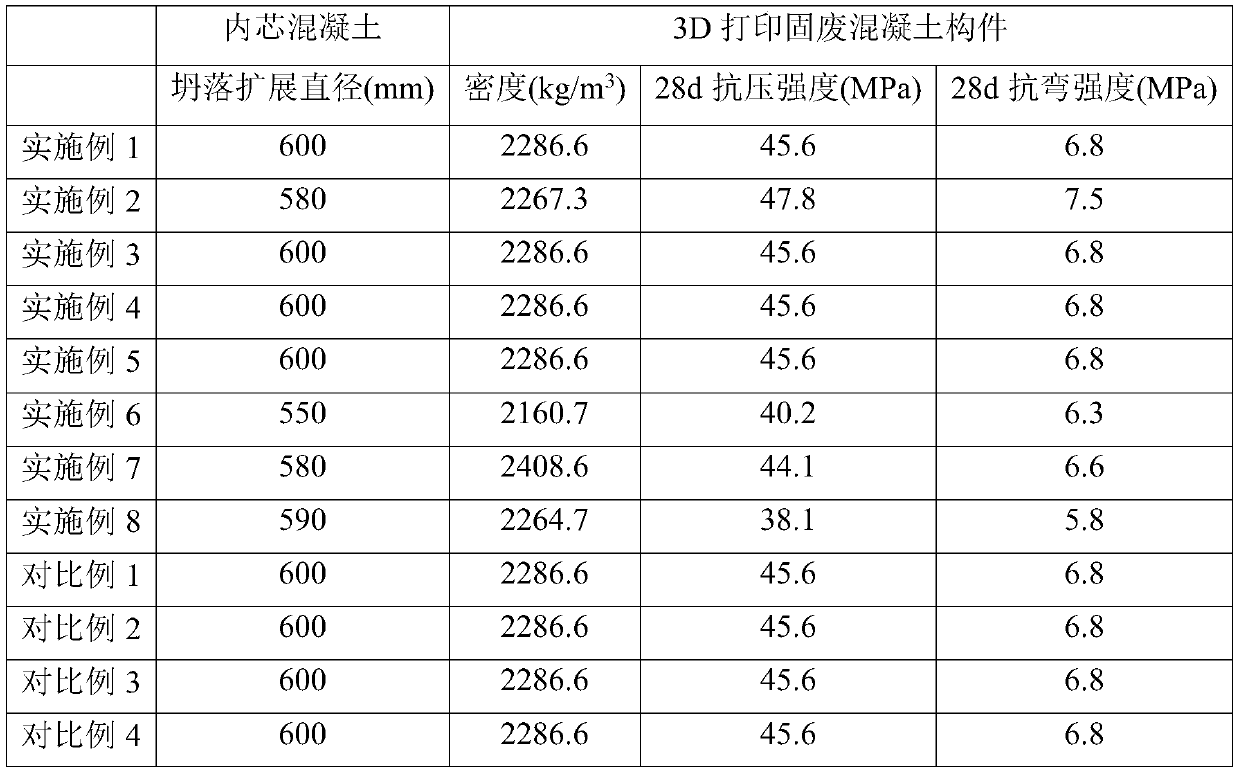

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned 3D printing solid waste concrete member comprises the following steps:

[0026] (1) Prepare 3D printing mortar template:

[0027] The 3D printing mortar template adopts two-stage mixing, the first-stage mixing: 0.56-0.74 parts of sulfoaluminate cement, 2.24-2.96 parts of ordinary Portland cement, 0.57-1.28 parts of fly ash, 0.23-0.0.59 parts of silicon Ash, 3.5-5.9 parts of quartz sand and 0.01-0.05 parts of lime are sent to a horizontal mortar mixer for mixing and stirring to obtain a mixed dry material; then 0.1-0.14 parts of water reducer and 1.2-1.5 parts of water are mixed and added to the above mixing Stir in the dry material for 4-10 minutes, then add 0.14-0.19 parts of regenerated glass fiber reinforced plastics, continue stirring until completely mixed to obtain cement mortar, and finally add recycled glass fiber reinforced plastics to facilitate fiber dispersion;

[0028] The second stage of mixing: pump or mechanic...

Embodiment 1

[0041] In this embodiment, a 3D printed solid waste concrete component, in parts by weight, the composition and content of the concrete component are:

[0042] 0.6 parts of rapid-hardening and early-strength sulfoaluminate cement;

[0043] Ordinary Portland cement 5.1 parts;

[0044] 0.78 parts of fly ash;

[0045] 0.25 parts of silica fume;

[0046] Mineral powder 0.3 parts;

[0047] Lime 0.02 part;

[0048] 3.5 parts of quartz sand,

[0049] 4.5 parts of ordinary river sand;

[0050] 6.8 parts of coarse aggregate;

[0051] 1 part of recycled FRP aggregate;

[0052] 0.06 parts of regenerated FRP powder;

[0053] 0.08 parts of alkali aggregate inhibitor;

[0054] 0.19 parts of water reducing agent;

[0055] 0.15 parts of regenerated fiberglass;

[0056] 0.12 parts of coagulant;

[0057] 2.5 parts of water.

[0058] The above raw materials are divided into two groups, the first group is 0.6 parts of rapid hardening and early strength sulfoaluminate cement; 2.5 part...

Embodiment 2

[0073] In this embodiment, a 3D printed solid waste concrete component, the composition and content of the concrete are as follows in parts by weight:

[0074] 0.7 parts of rapid-hardening and early-strength sulfoaluminate cement;

[0075] Ordinary Portland cement 7.5 parts;

[0076] 1.4 parts of fly ash;

[0077] 0.5 parts of silica fume;

[0078] 1.2 parts of mineral powder;

[0079] Lime 0.04 part;

[0080] 5.2 parts of quartz sand,

[0081] 6 parts of ordinary river sand;

[0082] 8.5 parts of coarse aggregate;

[0083] 1.2 parts of recycled FRP aggregate;

[0084] 0.06 parts of regenerated FRP powder;

[0085] 0.09 parts of alkali aggregate inhibitor;

[0086] 0.22 parts of water reducing agent;

[0087] 0.18 parts of regenerated glass fiber reinforced plastics;

[0088] 0.14 parts of coagulant;

[0089] 2.9 parts of water.

[0090] The above raw materials are divided into two groups, the first group is 0.7 parts of rapid hardening and early strength sulfoalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com