Anti-permeating and anti-cracking concrete and preparation method thereof

A concrete and anti-cracking technology, applied in the field of concrete, can solve the problems of poor impermeability and easy occurrence of cracks in feldspar waste concrete, so as to improve the impermeability and resistance to chemical corrosion, inhibit cracking, and reduce shrinkage cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A kind of anti-seepage and anti-cracking concrete, it is characterized in that: comprise the raw material of following parts by weight: 177 parts of water, 202 parts of cement, 734 parts of sand, 1002 parts of stones, 51 parts of fly ash, 60 parts of mineral powder , 3.79 parts of admixture; wherein the admixture includes modified polypropylene fiber, waterproofing agent and water reducer with a weight ratio of 3.2:1.3:1.7; modified polypropylene fiber is prepared by the following method: adding Potassium permanganate with a concentration of 5×10-3mol / L, add acrylic acid with a concentration of 0.8mol / L, and stir for 30 minutes, then drop a small amount of sulfuric acid solution with a concentration of 0.2mol / L, react for 32 minutes, and then add acrylic acid with a concentration of 0.8 mol / L acrylic acid, reacted at 80°C for 3.5 hours, filtered the mother liquor after the reaction, boiled the remaining solid with waste water, removed the homopolymer, carri...

Embodiment 2-9

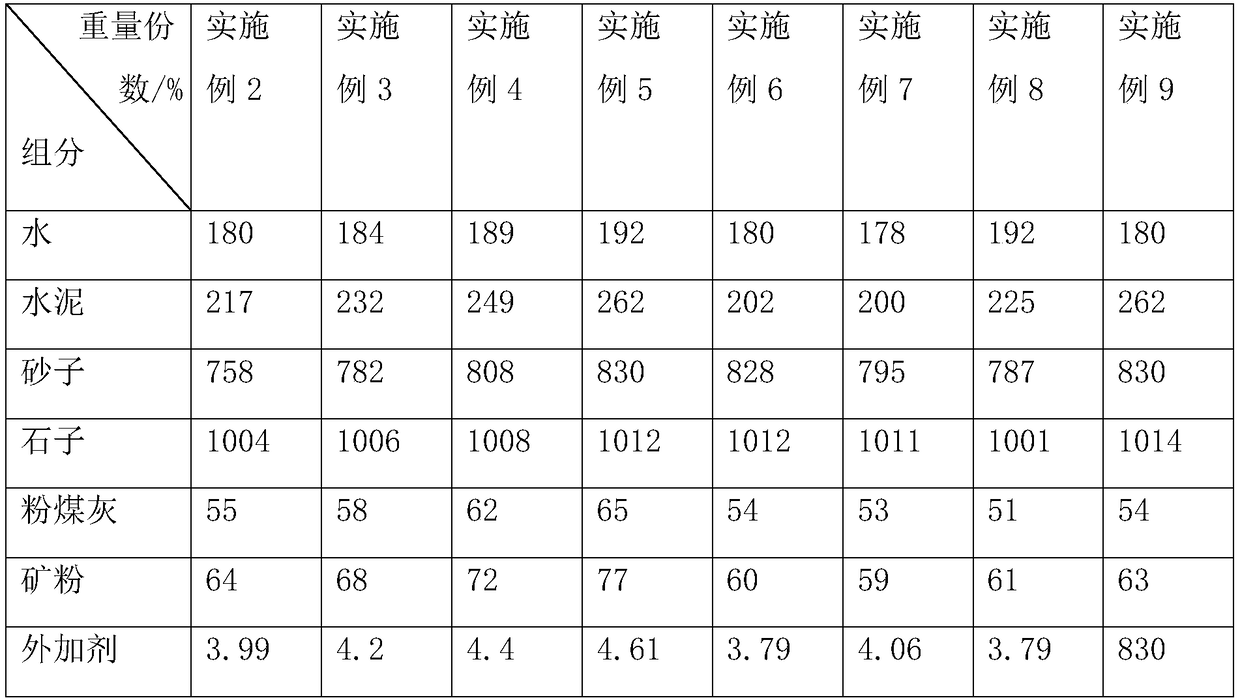

[0035] Embodiment 2-9, a super-retarded concrete, differs from Embodiment 1 in that the components included and the corresponding parts by weight are shown in Table 1.

[0036] Components included in Table 1 Embodiment 2-9 and their corresponding parts by mass

[0037]

Embodiment 10

[0038] Example 10: An anti-seepage and anti-crack concrete, the difference from Example 1 is that the admixture is composed of modified polypropylene fiber, waterproofing agent and water reducing agent with a mass ratio of 3.9:1.8:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com