Concrete pumping antifreezing agent with adjustable performances

A concrete pump and antifreeze technology, applied in the field of building materials, can solve the problems of antifreeze performance, poor early strength performance, low water reduction rate, poor volume stability performance, etc., achieves good antifreeze effect, improves impermeability, Good early strength enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The invention includes: naphthalenesulfonate formaldehyde condensation product water reducer, sulfamate water reducer, sodium lauryl sulfate air-entraining agent, tributyl fat fluidizing agent, sodium silicate strengthening agent, methanol antifreeze , Sodium sugar slump loss inhibitor.

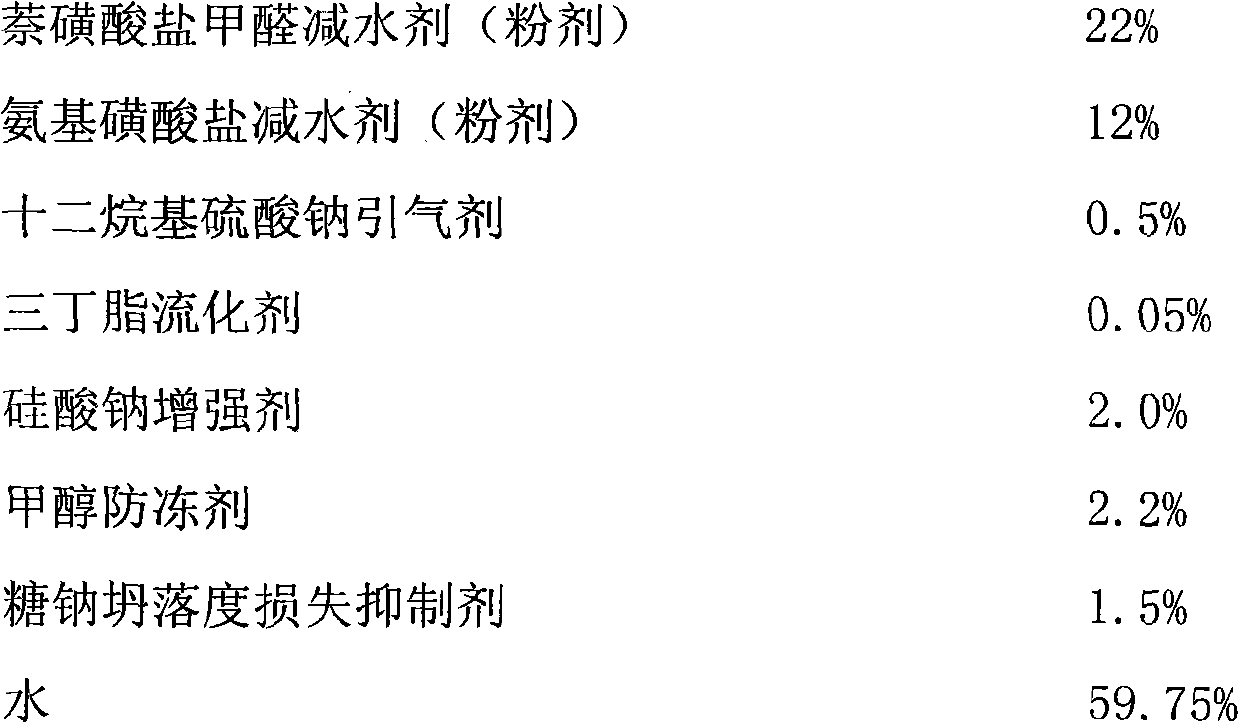

[0021] The proportioning of various materials by weight percentage is:

[0022]

[0023] The pumping antifreeze obtained in this example is mixed into concrete for use, and the dosage accounts for 2.0% of the cementitious material, and its performance is given in Table 1.

[0024] In this embodiment, due to the combined use of water reducing agent, antifreeze agent, reinforcing agent, and slump loss inhibitor, the water reducing rate of concrete is higher, and the effect of antifreeze and early strength is better. This amount is mainly used for C35 in winter construction. The pumping of the following concrete.

Embodiment 2

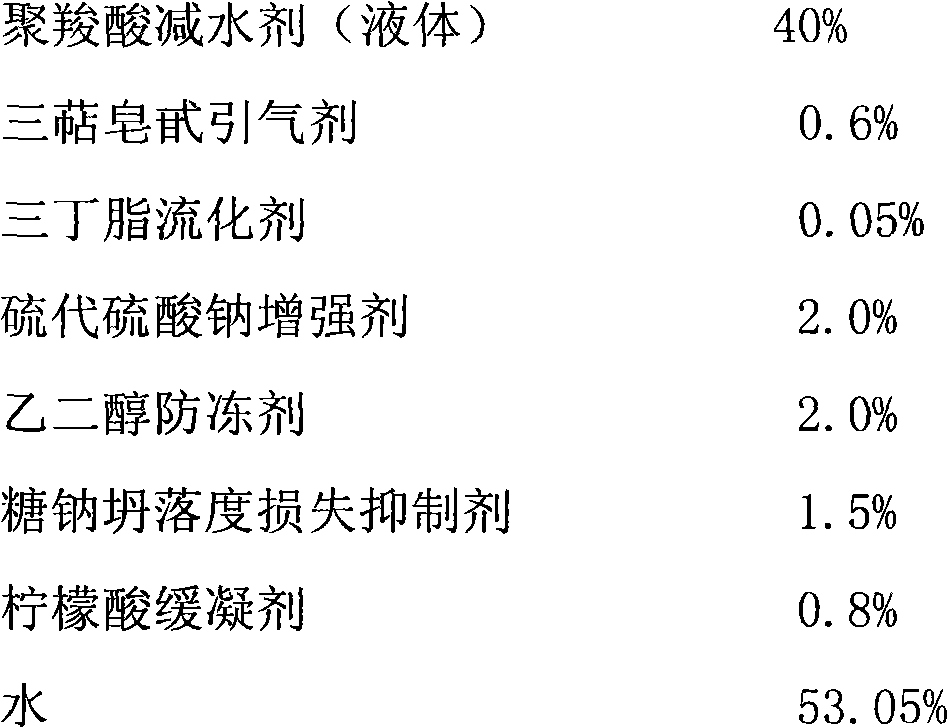

[0026] The invention includes: polycarboxylate water reducer, triterpene saponin air-entraining agent, tributyl fat fluidizing agent, sodium thiosulfate enhancer, ethylene glycol antifreeze, sugar sodium slump loss inhibitor, citric acid buffer coagulant.

[0027] The proportioning of various materials by weight percentage is:

[0028]

[0029] The pumping antifreeze obtained in this example is blended into concrete in an amount of 2% of the cementitious material, and its properties are shown in Table 1. In this embodiment, due to the optimal compound use of high-performance water-reducing agent, high-performance antifreeze agent, reinforcing agent, and slump loss inhibitor, the water-reducing rate of concrete is the highest, and the anti-freezing and early-strength enhancement functions are better. Winter construction is mainly used for pumping construction with C40-C60 high-strength concrete, and the cost of raw materials is relatively low at this time.

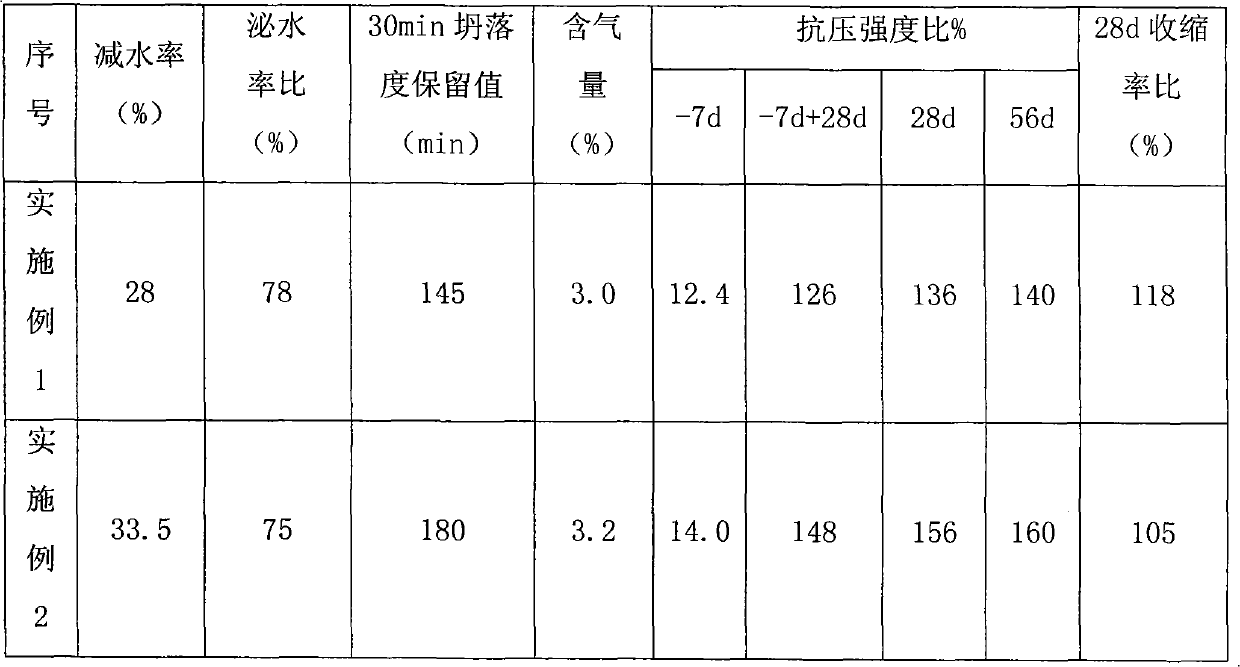

[0030] Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com