Fluidized bed combustion ash and high titanium slag compounded stable pavement base material

A pavement base material and high-titanium slag technology, which is applied in the field of road pavement-road engineering materials, can solve the problems of limited mass application and low activity, and achieve the goals of reducing drying shrinkage cracking, reducing hydration expansion, and shortening the project period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

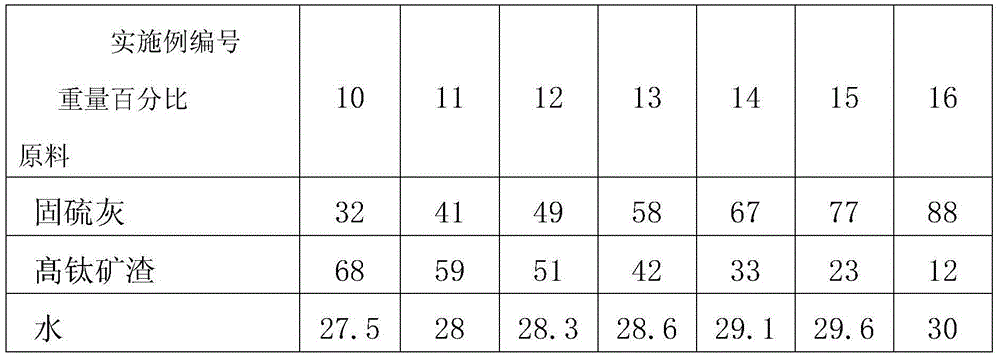

Examples

Embodiment 1

[0018] The invention discloses a composite stabilized pavement base material of sulfur-fixing ash and high-titanium slag. The content of sulfur-fixing ash is 30% by weight, and the content of high-titanium slag is 70% by weight. The measured value of the composite stabilized pavement base material of sulfur-fixed ash and high-titanium slag: the maximum dry density ρ is 1.429g / cm 3 , the optimal water content ω is 27.0%, and the 7-day unconfined compressive strength R 7d 2.49MPa, 28-day unconfined compressive strength R 28d 10.04MPa, 28d volume linear change rate -14.91×10 -4 .

Embodiment 2

[0020] The invention relates to a composite stabilized pavement base material of sulfur-fixing ash and high-titanium slag. The content of sulfur-fixing ash is 40% by weight, and the content of high-titanium slag is 60% by weight. The measured value of the composite stabilized pavement base material of sulfur-fixed ash and high-titanium slag: the maximum dry density ρ is 1.425g / cm 3 , the optimal water content ω is 27.2%, and the 7-day unconfined compressive strength R 7d 2.70MPa, 28-day unconfined compressive strength R 28d 10.87MPa, 28d volume linear change rate -6.12×10 -4 .

Embodiment 3

[0022] The invention discloses a composite stabilized pavement base material of sulfur-fixing ash and high-titanium slag. The content of sulfur-fixing ash is 50% by weight, and the content of high-titanium slag is 50% by weight. The measured value of the composite stabilized pavement base material of sulfur-fixed ash and high-titanium slag: the maximum dry density ρ is 1.421g / cm 3 , the optimal moisture content ω is 27.4%, and the 7-day unconfined compressive strength R 7d 3.20MPa, 28-day unconfined compressive strength R 28d 12.35MPa, 28d volume linear change rate is 0.17×10 -4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com