Mortar and concrete shrinkage reducing agent having antirust function, and preparation method thereof

A concrete shrinkage reducing agent and anti-rust technology, which is applied in the field of concrete admixtures, can solve problems such as gaps, achieve good results, reduce the risk of shrinkage cracking, and reduce the effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

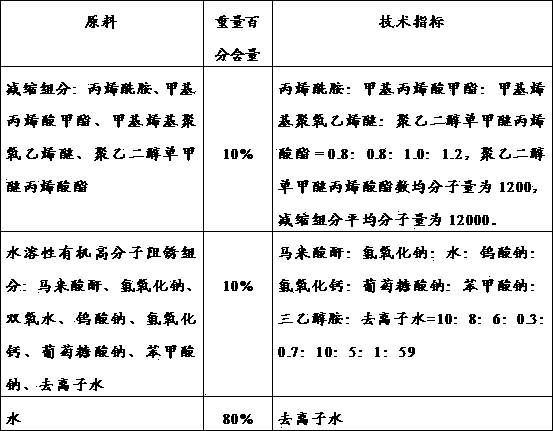

[0029] A formula of mortar and concrete shrinkage reducing agent with antirust function is:

[0030]

[0031] The preparation of the mortar and concrete shrinkage reducing agent with antirust function is carried out as follows:

[0032] (1) Preparation of shrinkage reduction components: Weigh 80kg of acrylamide, 80kg of methyl methacrylate, 120kg of polyethylene glycol monomethyl ether acrylate, add 440kg of water to make material A; weigh 1kg of ammonium persulfate, add 79kg of water Dissolved and made into material B;

[0033] Weigh 100kg of methyl alkenyl polyoxyethylene ether, add 100kg of water, raise the temperature to 60°C, and add material A and material B dropwise respectively. The dripping of material A takes 180 minutes, and the dropping of material B takes 210 minutes. Raise the temperature to 80, keep the temperature for 60 minutes, and cool down to 40℃, standby;

[0034] (2) Preparation of water-soluble organic polymer anti-rust components: Weigh the raw mat...

Embodiment 2

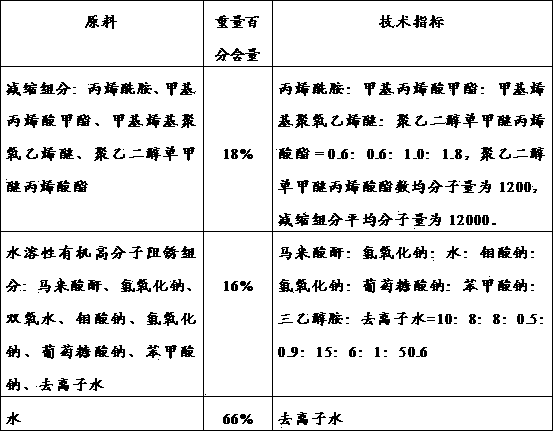

[0037] A formula of mortar and concrete shrinkage reducing agent with antirust function is:

[0038]

[0039] The preparation of the mortar and concrete shrinkage reducing agent with antirust function is carried out as follows:

[0040] (1) Preparation of shrinkage reduction components: Weigh 100kg of acrylamide, 100kg of methyl methacrylate, 160kg of polyethylene glycol monomethyl ether acrylate, add 360kg of water to make material A; weigh 1kg of ammonium persulfate, add 79kg of water Dissolved and made into material B;

[0041] Weigh 100kg of methyl alkenyl polyoxyethylene ether, add 100kg of water, raise the temperature to 60°C, add material A and material B dropwise respectively, the dripping of material A takes 180 minutes, the dropping of material B takes 210 minutes, heat up to 80, keep the temperature for 60 minutes, and cool down to 40℃, standby;

[0042] (2) Preparation of water-soluble organic polymer anti-rust components: Weigh the raw materials of water-solubl...

Embodiment 3

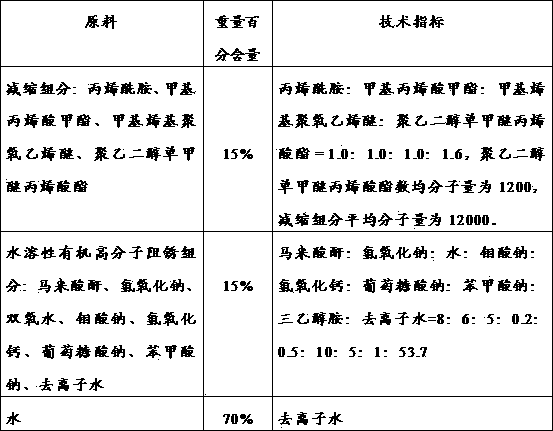

[0045] A formula of mortar and concrete shrinkage reducing agent with antirust function is:

[0046]

[0047] The preparation of the mortar and concrete shrinkage reducing agent with antirust function is carried out as follows:

[0048] (1) Preparation of shrinkage reduction components: Weigh 60kg of acrylamide, 60kg of methyl methacrylate, 180kg of polyethylene glycol monomethyl ether acrylate, add 420kg of water to make material A; weigh 1kg of ammonium persulfate, add 79kg of water Dissolved and made into material B;

[0049] Weigh 100kg of methyl alkenyl polyoxyethylene ether, add 100kg of water, raise the temperature to 60°C, and add material A and material B dropwise respectively. The dripping of material A takes 180 minutes, and the dropping of material B takes 210 minutes. Raise the temperature to 80, keep the temperature for 60 minutes, and cool down to 40℃, standby;

[0050] (2) Preparation of water-soluble organic polymer anti-rust components: Weigh the raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com