Preparation method of nano-wire reinforced SiC wear-resistant coating

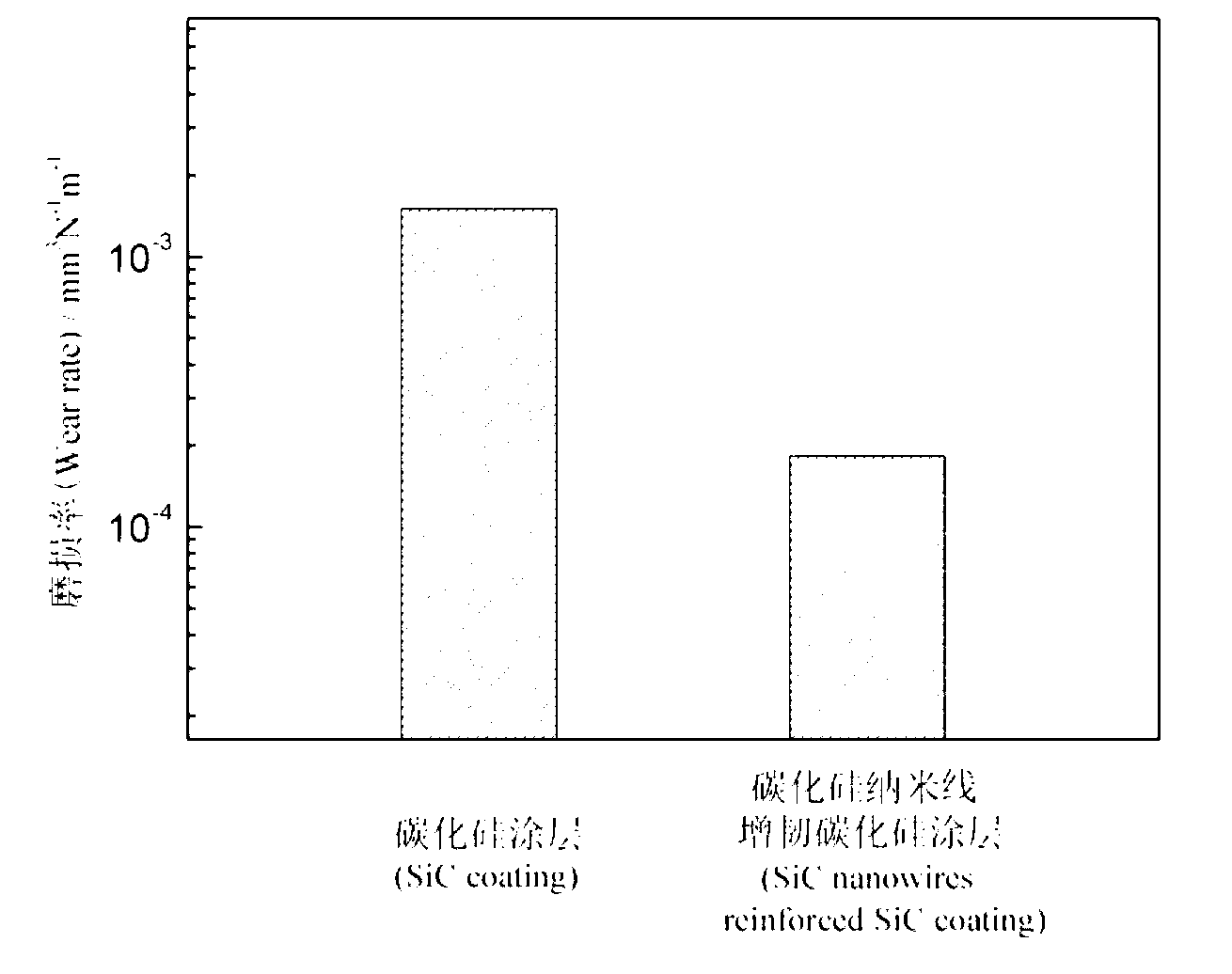

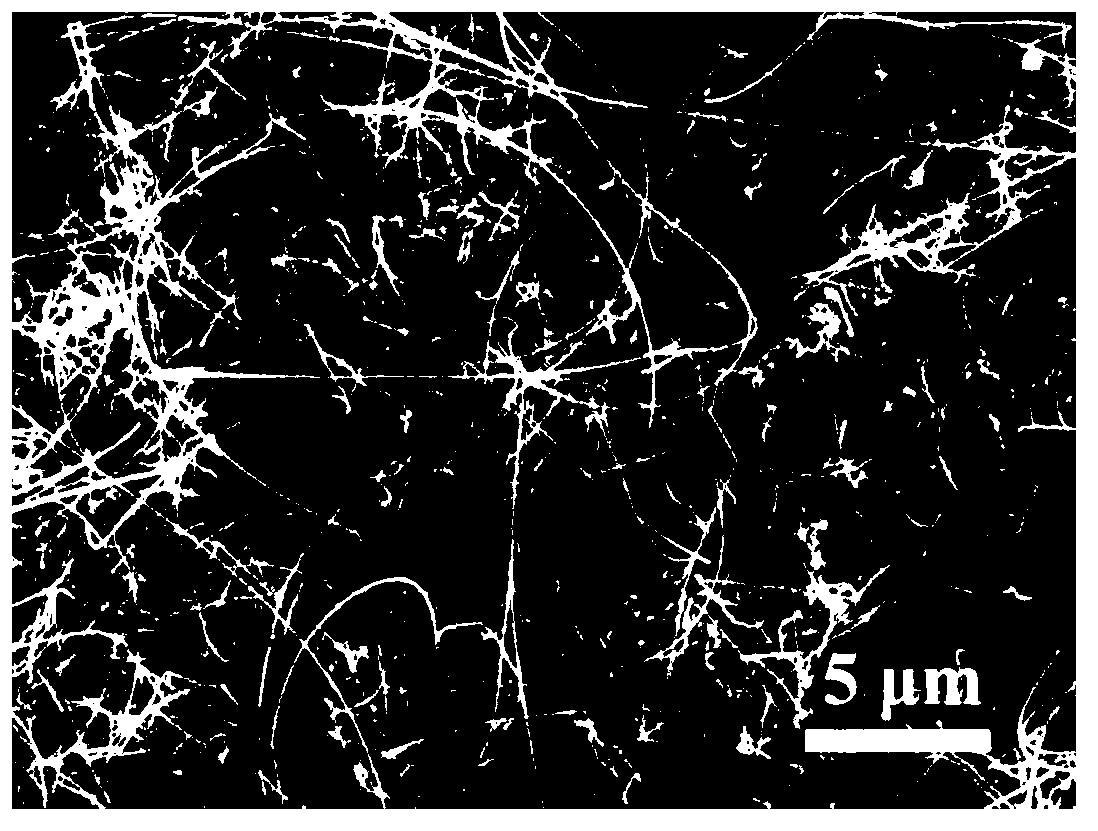

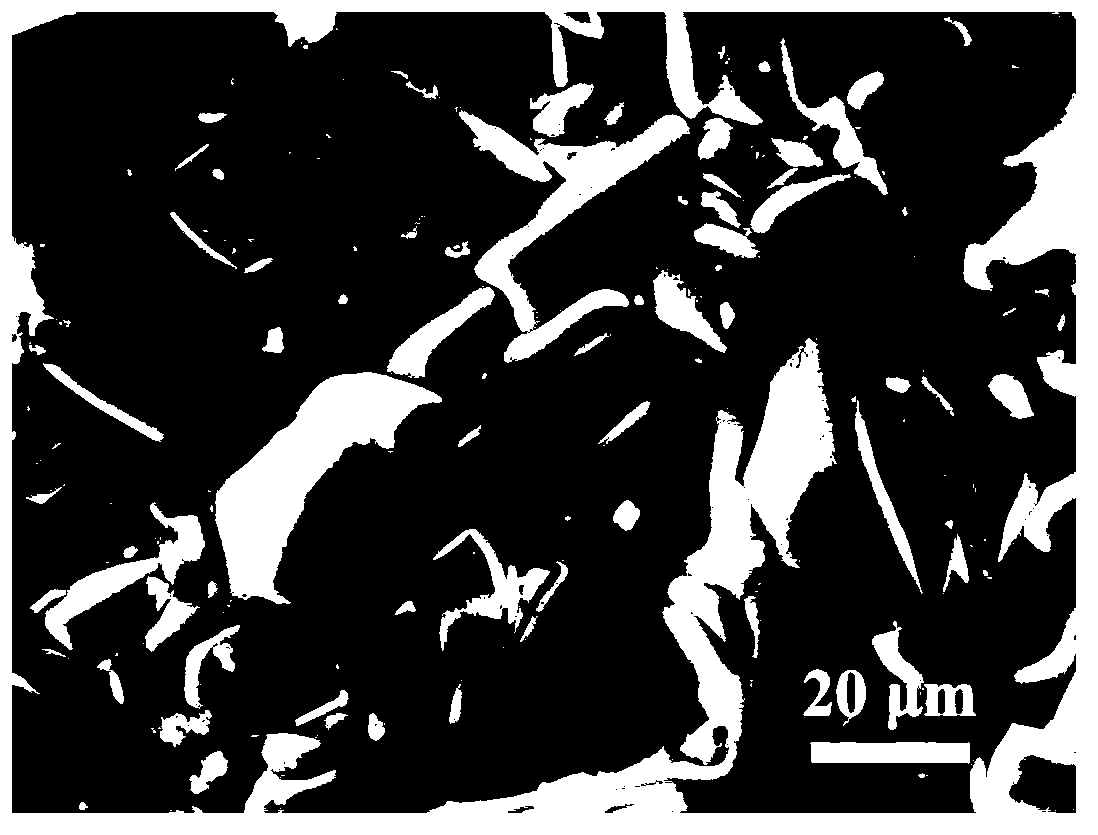

A wear-resistant coating and nanowire technology, which is applied in the preparation of nanowire-enhanced SiC wear-resistant coatings, can solve the problems of coating peeling failure, brittle fracture, etc., to reduce high temperature wear rate, improve wear resistance, The effect of improving fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Process the C / C composite material into The 36mm × 8mm round block samples were ground and polished, cleaned, and dried in an oven for later use.

[0027] 2) Weigh 15g Si powder, 25g C powder and 60g SiO 2 pink. Put it in a turpentine ball mill jar, take agate balls of different numbers and diameters into the ball mill jar, and perform ball milling and mixing treatment on a ball mill for 2 hours, as powder for use.

[0028] 3) Put the powder into a graphite crucible, so that the thickness of the powder is one-fifth of the depth of the crucible, and then tie the baked C / C composite material sample with a bunch of carbon ropes and hang it above the powder, Then put the graphite crucible into a vacuum heating furnace with graphite as a heating element. The vacuum in the furnace chamber was evacuated to 1kPa, and then argon was passed to normal pressure. This process is repeated three times. Then, the furnace temperature was raised to 1500°C at a heating rate of 5°...

Embodiment 2

[0032] 1) The density made by isothermal chemical vapor infiltration method is 1.67-1.76g / cm 3 The carbon / carbon composite material is processed into thin sheets with 400 # , 800 # , 1500 # Grinding and polishing with sandpaper in turn to the size of the sample 32mm×6mm. They were ultrasonically cleaned with tap water, acetone, anhydrous ethanol and distilled water, respectively, and air-dried. When cleaning, the ultrasonic frequency used is 20KHZ, the ultrasonic power is 100W, and the cleaning time is 25min.

[0033] 2) Weigh 10g of Si powder, 25g of C powder and 70g of SiO respectively 2 pink. Put it in a rosin ball mill tank, take agate balls of different numbers and diameters, put them in the rosin ball mill tank, and perform ball milling and mixing treatment on a planetary ball mill for 4 hours as powder for standby.

[0034] 3) Put the powder into the graphite crucible, so that the thickness of the powder is one-fifth of the depth of the graphite crucible, and th...

Embodiment 3

[0038] 1) Put the dimensions as The 36mm×8mm C / C composite material was polished and polished with 400, 800 and 1000 sandpapers in turn, washed with absolute ethanol, and dried in an oven for use.

[0039] 2) Weigh 15g of Si powder, 30g of C powder and 75g of SiO respectively 2 pink. Put it in a rosin ball mill jar, take agate balls of different numbers and diameters, put them in the rosin ball mill jar, and perform ball milling and mixing treatment on a planetary ball mill for 3 hours as powder for use.

[0040] 3) Put the powder into the graphite crucible so that the thickness of the powder is one-fifth of the depth of the graphite crucible, and then bind the baked C / C composite material with a bundle of 3K carbon fibers and hang it on the surface of the powder. above, and then put the graphite crucible into the vacuum reactor. After 30 minutes of vacuuming, the vacuum degree reaches 1kPa, and the vacuum is maintained for 30 minutes. Observe whether the indication of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com