Rotary joint with temperature difference zone structure

A rotary joint and temperature difference technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of poor rotation stability of the outer pipe, failure of the input medium seal, and product pollution in the production environment, so as to reduce mechanical The effect of processing cost, good sealing performance and easy structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

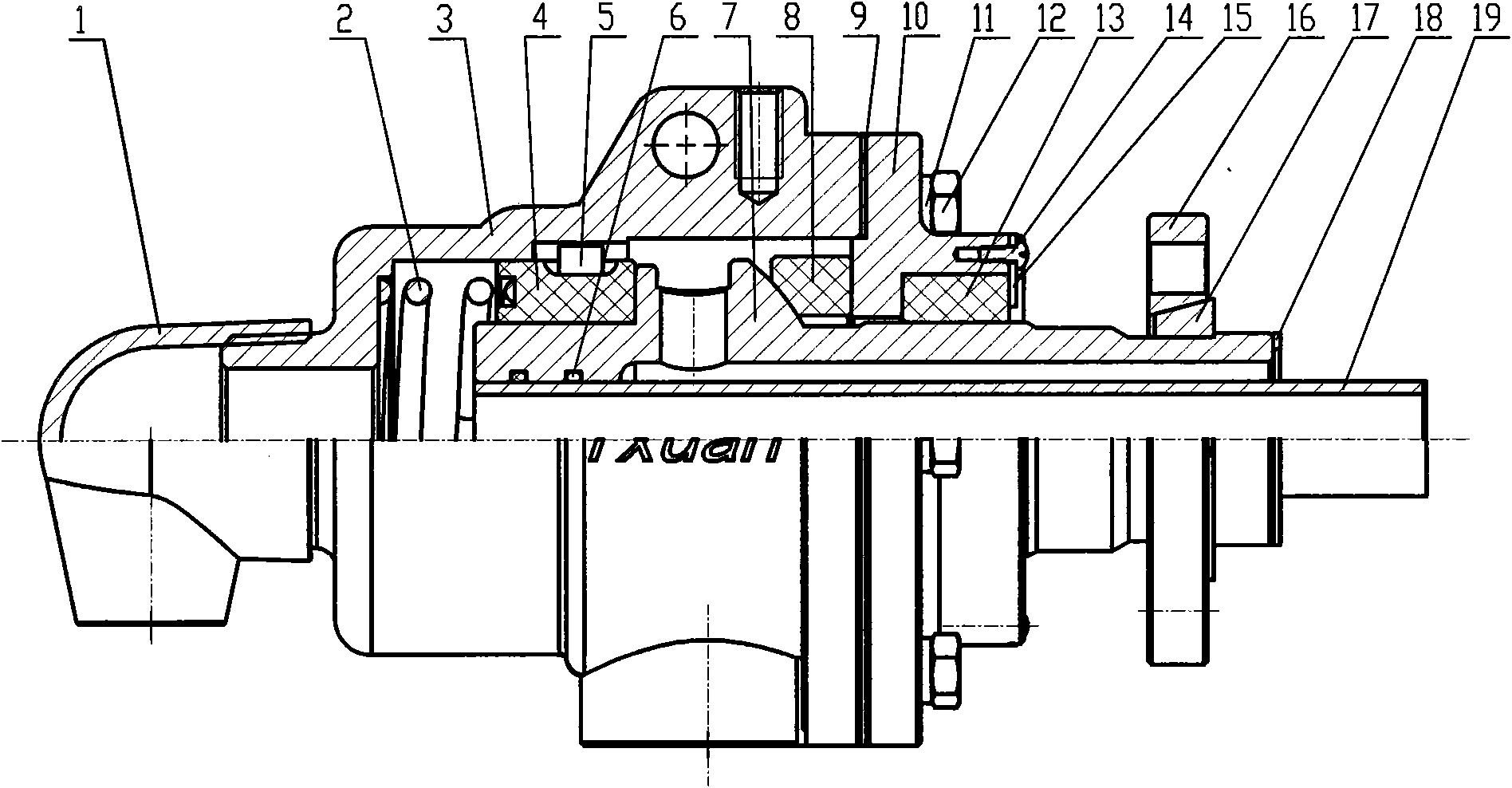

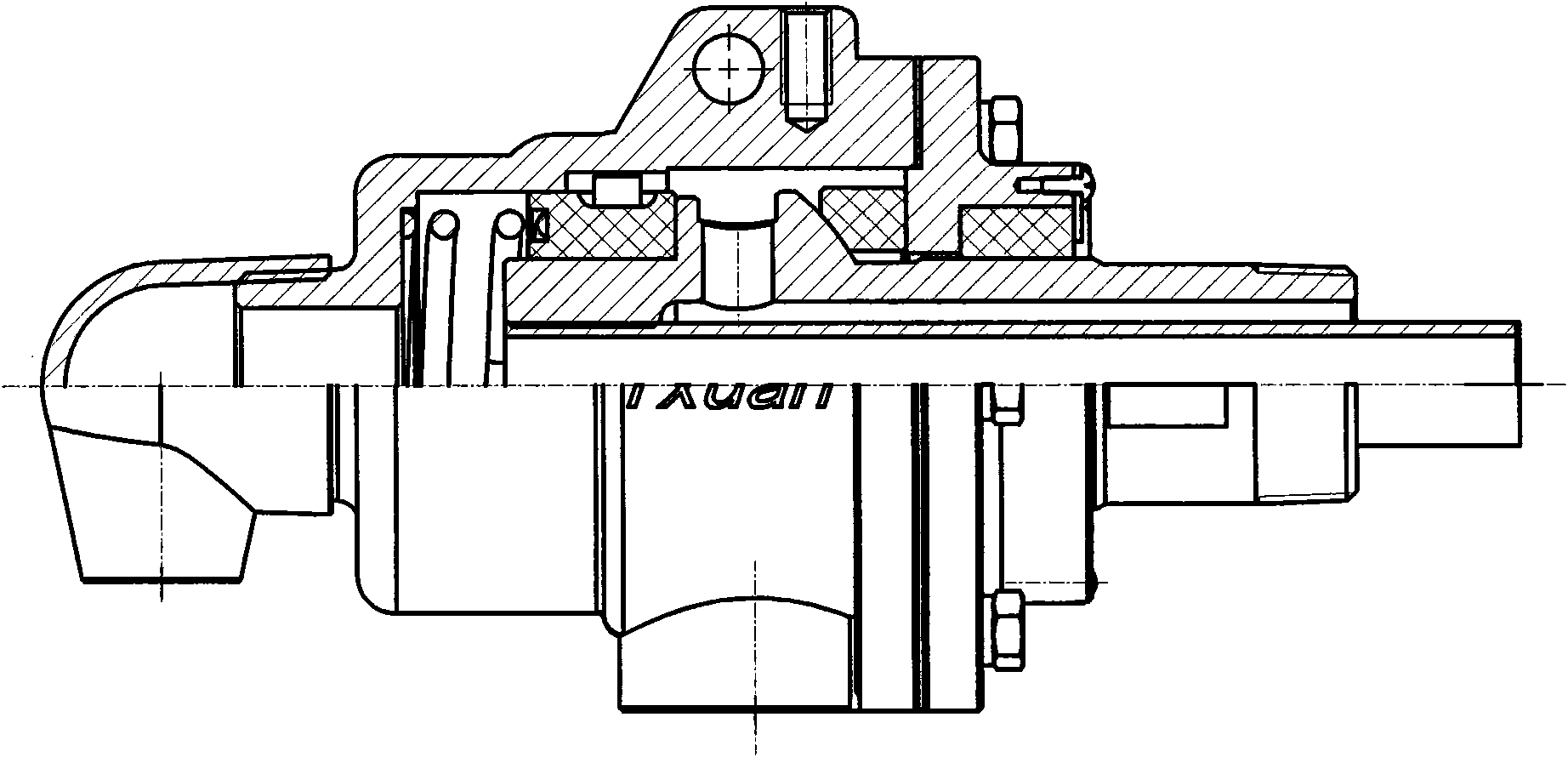

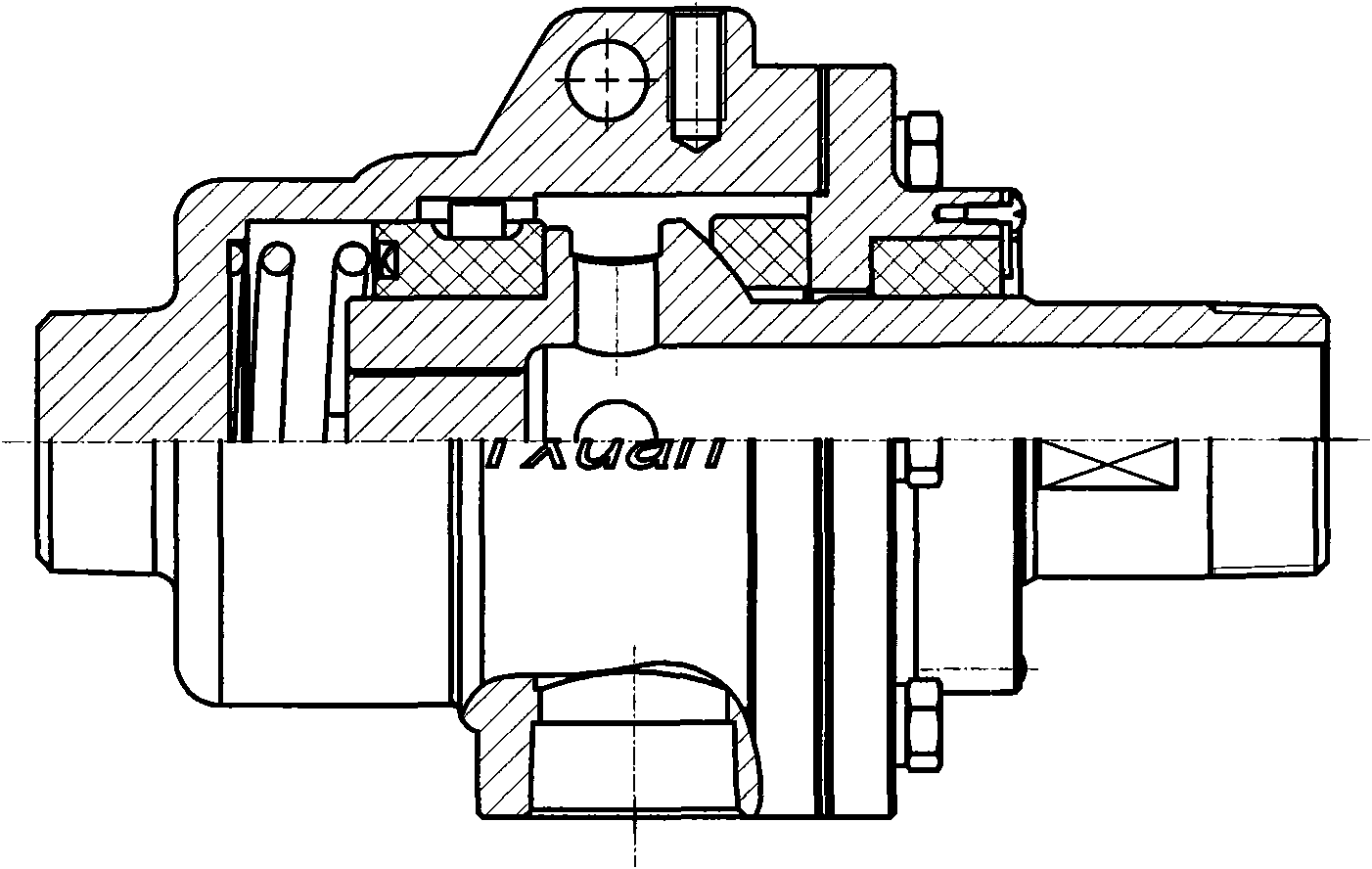

[0014] Such as figure 1 As shown, a rotary joint with a temperature difference zone structure includes a housing 3, a cylindrical spring 2 mounted on the inner bottom of the housing 3, and an outer tube 7 located in the housing 3; the bottom of the cylindrical ring 4 The end face groove is embedded in the end face of the cylindrical spring 2, the outer tube 7 is inserted into the inner hole of the cylindrical ring 4, the inner hole of the tail of the outer tube 7 is provided with an O-ring 6 and the outer tube 7 is provided There is a medium inlet, one side of the medium inlet is in sliding contact with the cylindrical ring 4, and a spherical ring 8 is sleeved on the spherical surface on the other side.

[0015] The cylindrical spring 2 of the sealing compensation structure is separated from the high-temperature medium inlet on the outer tube 7 through the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com