Production method of waste plastic regenerated particles

A technology of waste plastic and production method, applied in the field of waste plastic recycling, can solve the problems of brittleness, poor toughness, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

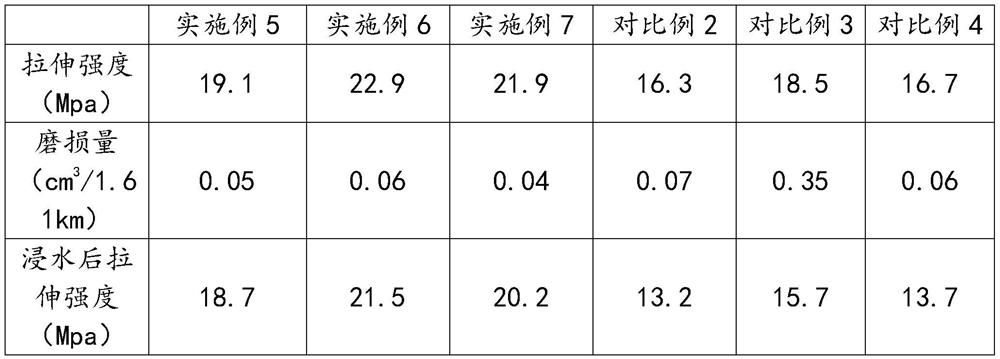

Examples

Embodiment 1

[0037] Preparation of diamine monomer:

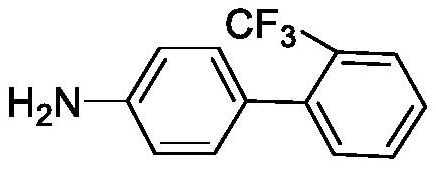

[0038] B1, 0.01mmol PdCl 2and 2 mL of water / acetone mixed solvent (the volume ratio of water and acetone is 1:4) was stirred in a water bath at 65 ° C for 30 min, cooled to room temperature, and then 1 mmol 2-chloro-trifluorotoluene and 1.2 mmol 4-aminophenylboronic acid were added and 1.5 mmol K 3 PO 4 ·3H 2 O, after mixing evenly, seal the reaction, heat to reflux, react for 12h, stop the reaction, cool to room temperature, add water, then extract with 5mL diethyl ether multiple times, combine the extracts, and then separate through the column to obtain the biphenyl derivative;

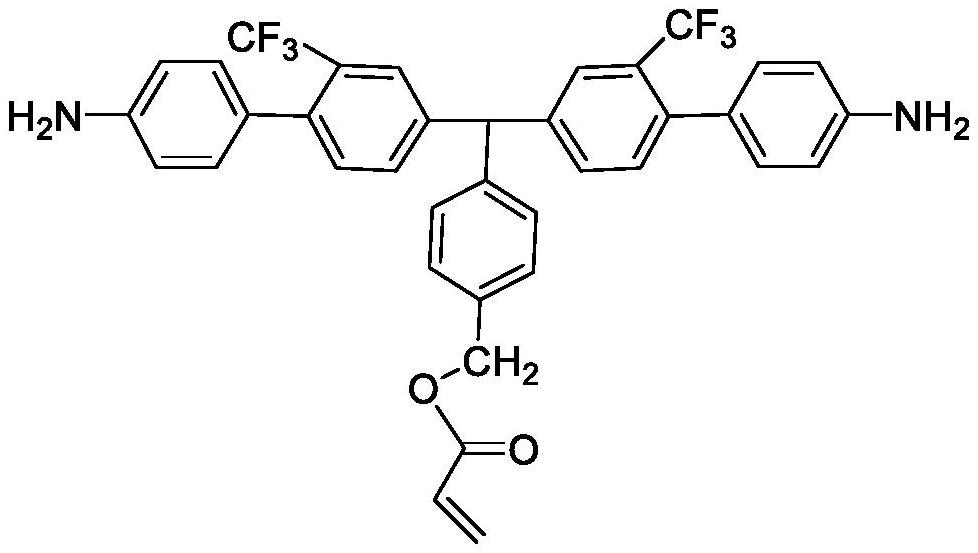

[0039] B2. Dissolve 0.1mol of 4-hydroxymethylbenzaldehyde in isopropanol, then add 0.1mol of acrylic acid and 0.36g of p-toluenesulfonic acid, heat to 56°C, stir for 4 hours, stop the reaction, and rotate under reduced pressure to obtain Intermediate product: Dissolve 0.21mol of biphenyl derivatives and 0.1mol of intermediate in glacial acetic acid, add d...

Embodiment 2

[0041] Preparation of diamine monomer:

[0042] B1, 0.01mmol PdCl 2 and 5 mL of water / acetone mixed solvent (the volume ratio of water and acetone is 1:4), stirred in a water bath at 65°C for 30 min, cooled to room temperature, and then added 1 mmol 2-chloro-trifluorotoluene and 1.5 mmol 4-aminophenylboronic acid and 2 mmol K 3 PO 4 ·3H 2 O, after mixing evenly, seal the reaction, heat to reflux, react for 12h, stop the reaction, cool to room temperature, add water, then extract with 5mL diethyl ether multiple times, combine the extracts, and then separate through the column to obtain the biphenyl derivative;

[0043] B2. Dissolve 0.1mol 4-hydroxymethylbenzaldehyde in isopropanol, then add 0.1mol acrylic acid and 0.72g p-toluenesulfonic acid, heat to 56°C, stir for 4 hours, stop the reaction, and spin evaporate under reduced pressure to obtain Intermediate product: Dissolve 0.23mol of biphenyl derivatives and 0.1mol of intermediate in glacial acetic acid, add dropwise a mi...

Embodiment 3

[0045] Preparation of dendritic elastomers:

[0046] A1. Add 0.1mol pentaerythritol, 0.41mol 1,4-cyclohexanedioic acid and 80mL isopropanol into a three-necked flask with a reflux condenser and a stirring magnet, stir evenly, add 0.4g p-toluenesulfonic acid, and reflux reaction After 4 hours, cool down to 50°C and dissolve with 80 mL of acetone, then precipitate with 50 mL of n-hexane, and dry in vacuum to constant weight to obtain carboxyl-terminated polyester;

[0047] A2. Mix 0.1mol of carboxy-terminated polyester, 0.4mol of diisocyanate and 80mL of anhydrous dichloromethane, heat to 82°C, react for 3 hours, add 0.4mol of the diamine monomer prepared in Example 1, and continue the reaction for 4 hours , rotary evaporation under reduced pressure, and vacuum drying at 50°C to constant weight to obtain a dendritic elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com