A kind of production method of pure cotton high count and high density compact sizing yarn

A high-count, high-density, sizing method technology, which is applied in the processing of textile materials, textile and papermaking, processing textile material carriers, etc., can solve the problems of brittleness and low weaving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Before sizing, the moisture regain of the yarn on the warp beam is controlled to 35%, and the yarn is sequentially subjected to sizing treatment, drying treatment, dry splitting treatment, waxing treatment and coiling treatment, and the unwinding tension of the warp beam is 550N , the traction tension of the sizing tank is 350N, the sizing tension is 2140N during the waxing process, the sizing tension is 2200N during the dry splitting process, and the coiling tension during the coiling process is 2250N. No delamination or wet splitting treatment is performed. In the drying process, slow train operation is adopted in the drying area, and the drafting tension is increased. The speed of the machine is controlled at 45m / min. During the drying process, the yarn tension is 600N, and the yarn The moisture regain is controlled at 9%, the viscosity of the size tank is controlled at 7s, the solid content is controlled at 11%, and the sizing rate is controlled at 10%.

Embodiment 2

[0052] Before sizing, the moisture regain of the yarn on the warp beam is controlled to 25%, and the yarn is sequentially subjected to sizing treatment, drying treatment, dry splitting treatment, waxing treatment and coiling treatment, and the unwinding tension of the warp beam is 500N , the traction tension of the sizing tank is 300N, the sizing tension is 1920N during the waxing process, the sizing tension is 2000N during the dry splitting process, and the coiling tension during the coiling process is 2000N. No delamination, no wet split twisting treatment, in the drying process, use slow train operation in the drying area, increase the draft tension, control the speed of the machine to 35m / min, during the drying process, the yarn tension is 500N, the yarn The moisture regain is controlled at 8%, the viscosity of the size tank is controlled at 7s, the solid content is controlled at 11%, and the sizing rate is controlled at 10%.

Embodiment 3

[0054] Before sizing, the moisture regain of the yarn on the warp beam is controlled to 30%, and the yarn is sequentially subjected to sizing treatment, drying treatment, dry splitting treatment, waxing treatment and coiling treatment, and the unwinding tension of the warp beam is 550N , the traction tension of the sizing tank is 325N, the sizing tension is 2030N during the waxing process, the sizing tension is 2100N during the dry splitting process, and the coiling tension during the coiling process is 2125N. No delamination or wet splitting treatment is carried out. During the drying process, the slow train operation is adopted in the drying area, the drafting tension is increased, and the speed is controlled at 40m / min. During the drying process, the yarn tension is 550N, and the yarn The moisture regain is controlled at 7%, the viscosity of the size tank is controlled at 7s, the solid content is controlled at 11%, and the sizing rate is controlled at 10%.

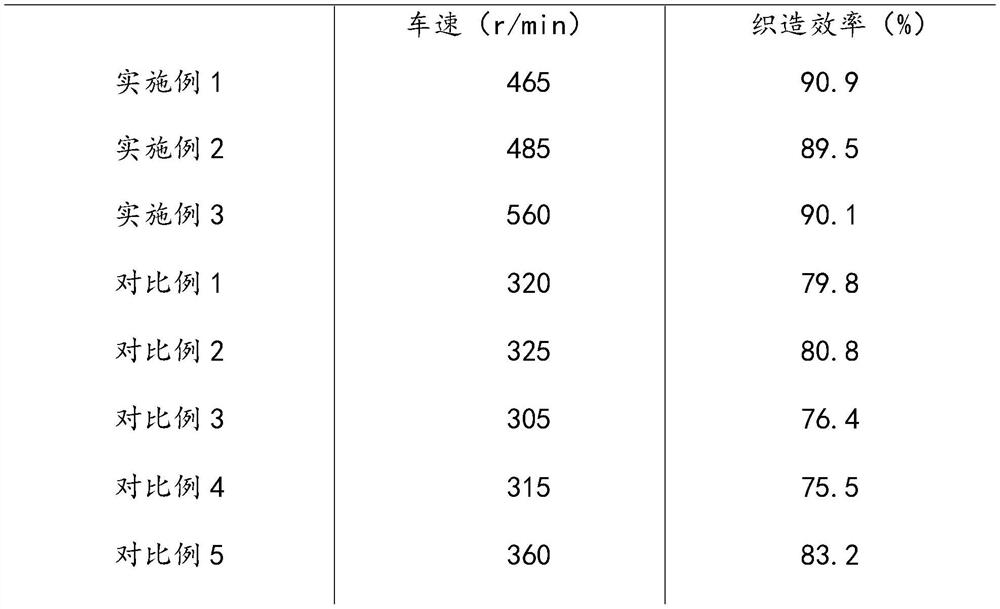

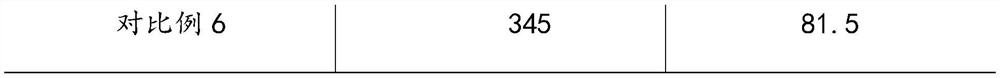

[0055] With JC7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com