Knitting platform for X type and Y type knitted fabrics

A woven fabric and platform technology, which is applied in the direction of woven fabrics, textiles and papermaking, can solve the problems of low weaving efficiency and achieve the effect of optimizing layout and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

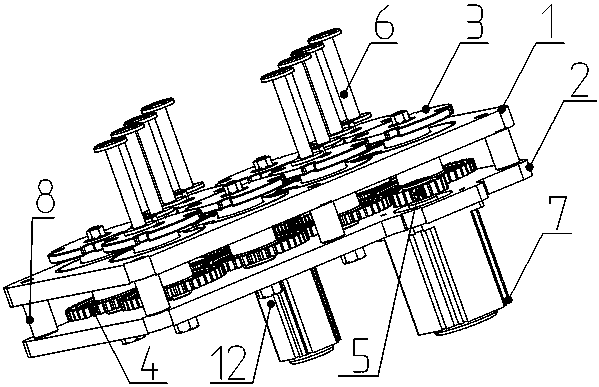

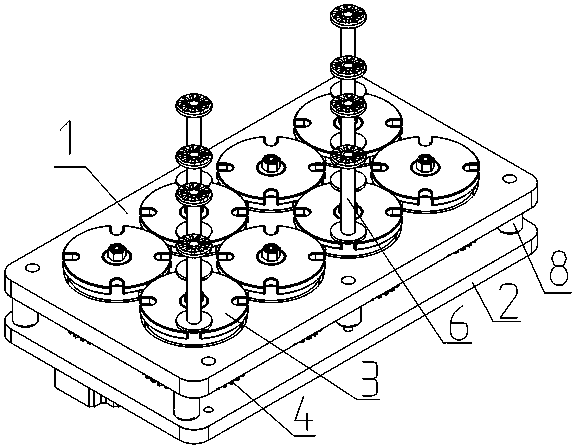

[0049] Embodiment 1: see specification attached figure 1 to attach Figure 10 shown.

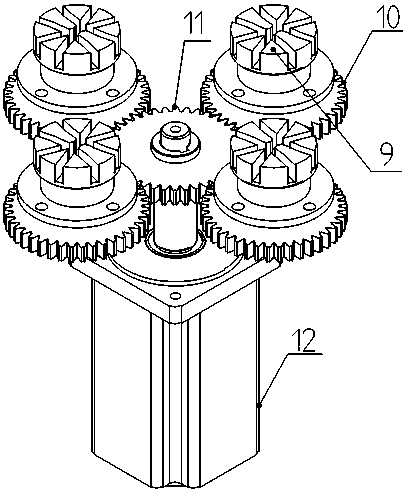

[0050] The present invention is a weaving platform capable of realizing X and Y-shaped braids, comprising a weaving upper plate 1, a weaving bottom plate 2, a weaving dial 3, a dial gear 4, a weaving driving gear 5, a yarn carrier 6, and a dial driving motor 7. Support column 8, rotatable track block 9, track block gear 10, track block driving gear 11, track block rotating element 12, fixed track block 13 and track groove 14;

[0051] The fixed track block 13, the rotatable track block 9 and the track groove 14 are all located on the weaving upper plate 1;

[0052] Fixed track piece 13, rotatable track piece 9 all is cylindrical shape, and fixed track piece 13 has only two crossed tracks, and rotatable track piece 9 both has two crossed tracks and also has two circular arc tracks.

[0053] The braiding dial 3 is connected with the dial gear 4, and the dial gear 4 meshes with the knitting dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com