A kind of high-entropy alloy reinforced by ceramic particles and its preparation method

A technology of high-entropy alloys and ceramic particles, which is applied in the field of high-entropy alloys reinforced by ceramic particles and its preparation, can solve the problems of difficult uniform distribution of metal solutions, high toxicity of chemical reagents, and high environmental protection requirements, so as to reduce brittle fracture The possibility of occurrence, low cost, and the effect of improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

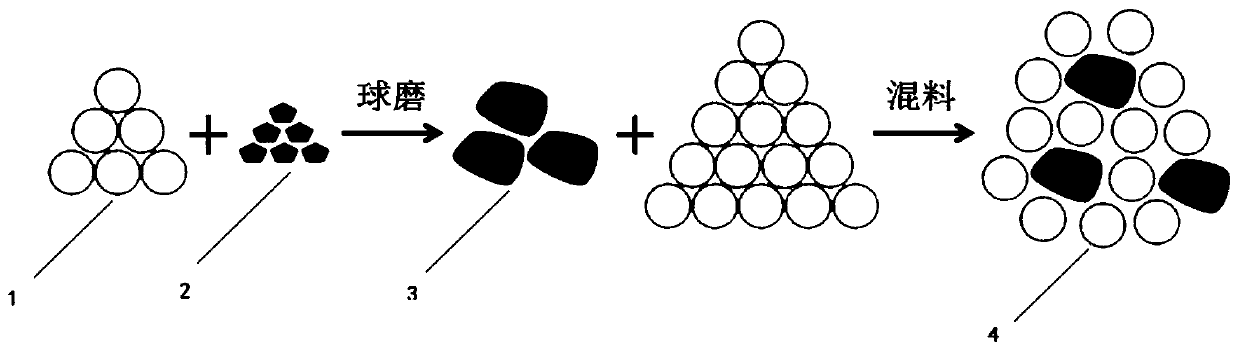

[0033] 1) Take alumina particles with a particle size of 20-30um, FeMnCoCr high-entropy alloy powder with a particle size of 80-100um and an atomic ratio of 4:4:1:1, the weight ratio of the two is 0.5wt.%; take 5 The % high-entropy alloy powder is ball-milled with alumina particles as the first part, and the ball-milling parameters are as follows: the ball-to-material ratio is 2:1, the rotating speed is 200rpm, and the ball-milling time is 2h to obtain high-entropy-ceramic alloy powder;

[0034] 2) uniformly mixing the high-entropy-ceramic alloy powder and the remaining high-entropy powder for 40 minutes to obtain a mixed powder;

[0035] 3) Prepress the mixed powder under a pressure of 400Mpa to obtain a prepress;

[0036] 4) Put the prepress in N with a volume ratio of 9:1 2 and H 2 In the atmosphere, sintering is carried out at 1000 ° C, and naturally cooled after sintering.

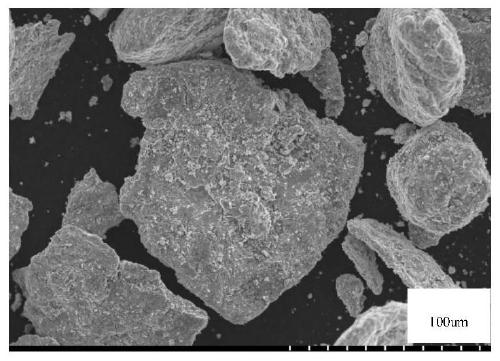

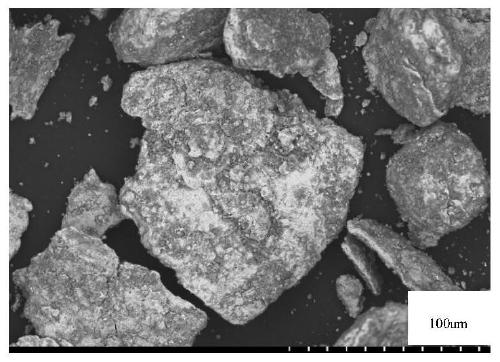

[0037] see Figure 2a , Figure 2b , Figure 2a and Figure 2b They are the SEM image and t...

Embodiment 2

[0040] 1) Take ZrO with a particle size of 10-20um 2 Particles, FeMnCoCr high-entropy alloy powder with a particle size of 60-80um and an atomic ratio of 5:3:1:1, the weight ratio of the two is 0.3wt.%; take 7% high-entropy alloy powder as the first part and ZrO 2 Carry out ball milling, and the ball milling parameters are as follows: the ball-to-material ratio is 2:1, the rotating speed is 300rpm, and the ball milling time is 1.5h to obtain high-entropy-ceramic alloy powder;

[0041] 2) uniformly mixing the high-entropy-ceramic alloy powder and the remaining high-entropy powder for 30 minutes to obtain a mixed powder;

[0042] 3) prepress the mixed powder under a pressure of 500Mpa to obtain a prepress;

[0043] 4) Put the pre-pressed part at a volume ratio of 19:1 N 2 and H 2 In the atmosphere, sintering is carried out at 1050°C, and it is naturally cooled after sintering.

Embodiment 3

[0045] 1) Take SiC particles with a particle size of 10-15um, FeMnCoCr high-entropy alloy powder with a particle size of 40-60um and an atomic ratio of 1:1:1:1, the weight ratio of the two is 0.1wt.%; take 10% The high-entropy alloy powder is used as the first part to perform ball milling with SiC particles. The ball-milling parameters are as follows: the ball-to-material ratio is 2:1, the rotating speed is 400rpm, and the ball-milling time is 1h to obtain high-entropy-ceramic alloy powder;

[0046] 2) uniformly mixing the high-entropy-ceramic alloy powder and the remaining high-entropy powder for 25 minutes to obtain a mixed powder;

[0047] 3) Prepress the mixed powder under a pressure of 600Mpa to obtain a prepress;

[0048] 4) Put the prepress in 19:1 Ar and H 2 In the atmosphere, sintering is carried out at 1050°C, and it is naturally cooled after sintering.

[0049] Other embodiments provided by the present invention are shown in Table 1:

[0050] Table 1 is the detaile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com