Titanium alloy artificial joint with bio-lubrication surface layer and preparation method thereof

An artificial joint, titanium alloy technology, applied in coating, tissue regeneration, medical science and other directions, can solve problems affecting quality and service life, adverse physiological reactions, artificial joint failure, etc., to achieve large-scale production, excellent mechanical properties , Improve the effect of biological lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

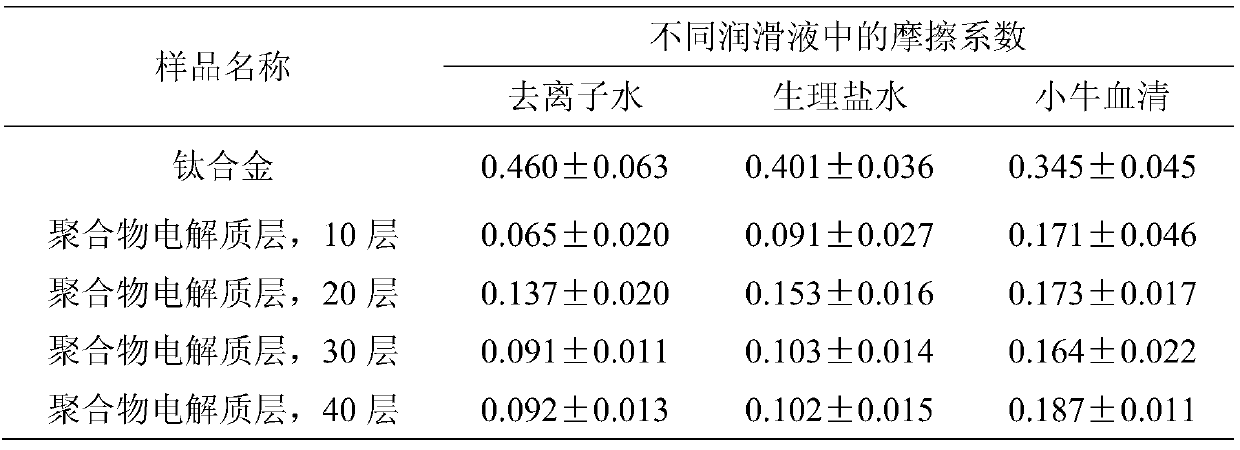

[0038] The method for preparing a titanium alloy artificial joint with a biolubricating surface generally adopts the following steps:

[0039] (1) Prepare polyelectrolyte solution: prepare polycation electrolyte solution and polyanion electrolyte solution respectively;

[0040] (2) carrying out hydroxylation treatment on the titanium alloy substrate to form a hydroxylation substrate;

[0041] (3) layer by layer self-assembled polyelectrolyte layer, including the following sub-steps:

[0042](3.1) Soak the hydroxylated substrate in a polycation electrolyte solution to form a polycation electrolyte layer, take it out, clean it and dry it;

[0043] (3.2) Then put it into the polyanion electrolyte solution for soaking to form a polyanion electrolyte layer, take it out, clean it and dry it;

[0044] (3.3) Steps (3.1) and (3.2) are repeated in sequence to form a multilayer polymer electrolyte layer with N layers of polycation electrolyte layers and N layers of polyanion electrolyt...

Embodiment 1

[0056] Preparation of 1# titanium alloy artificial joint with biolubricating surface.

[0057] Prepare 1mg / mL polydiallyldimethylammonium chloride aqueous solution and 1mg / mL polyacrylic acid aqueous solution respectively; carry out oxygen plasma treatment on the titanium alloy substrate for 5min to obtain the hydroxylated substrate; immerse the hydroxylated substrate In the aqueous solution of polydiallyldimethylammonium chloride for 5 minutes, take it out and wash it with deionized water and dry it, then immerse it in the aqueous solution of polyacrylic acid for 5 minutes, take it out and wash it with deionized water and dry it; The solution was submerged five times successively, and a multilayer polymer electrolyte layer with five layers of polycation electrolyte layers and five layers of polyanion electrolyte layers stacked alternately was formed on the titanium alloy substrate. Made 1# titanium alloy artificial joint with biological lubricating surface.

Embodiment 2

[0059] Preparation of 2# titanium alloy artificial joint with biolubricating surface.

[0060] Prepare 2 mg / mL polyacrylamine hydrochloride aqueous solution and 2 mg / mL polymethacrylic acid aqueous solution respectively; treat the titanium alloy substrate with Piranha solution, and keep it in a water bath at 80°C for 60 minutes to obtain a hydroxylated substrate; immerse the hydroxylated substrate in polyhydrochloric acid Acrylamine aqueous solution for 60 minutes, take it out and wash it with deionized water and dry it, then immerse it in polymethacrylic acid aqueous solution for 60 minutes, take it out and wash it with deionized water and blow it dry; A multilayer polymer electrolyte layer with 10 layers of polycation electrolyte layers and 10 layers of polyanion electrolyte layers stacked alternately is formed on the titanium alloy substrate. Made 2# titanium alloy artificial joint with biological lubricating surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com