Connection structure of porous surface structure and substrate, preparation method and prosthesis

A technology of surface structure and porous structure, which can be used in prosthetics, medical science, joint implants, etc., and can solve problems such as the sharp decline in the mechanical properties of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

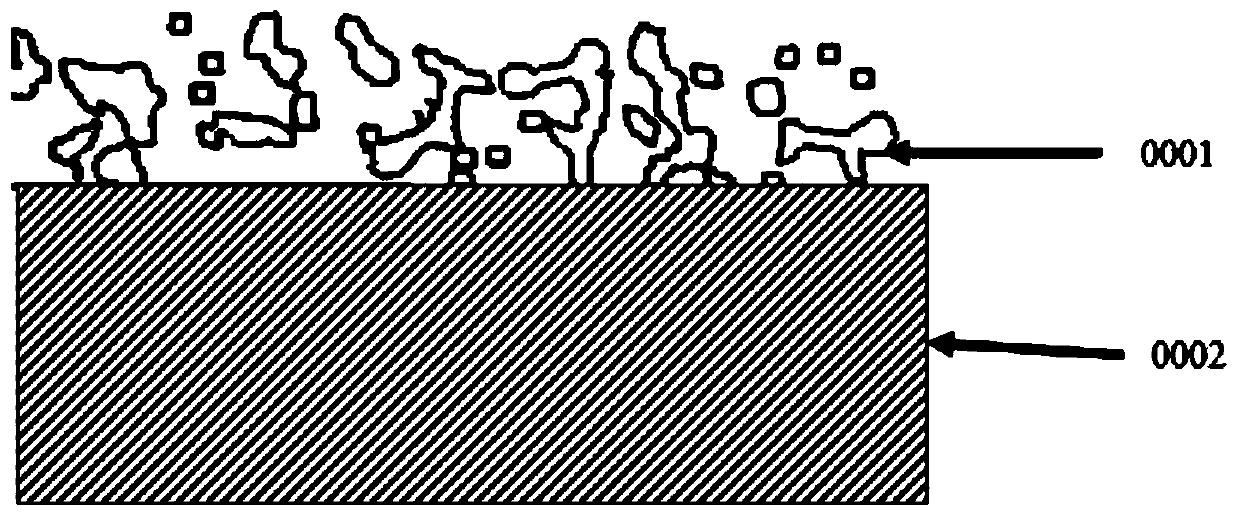

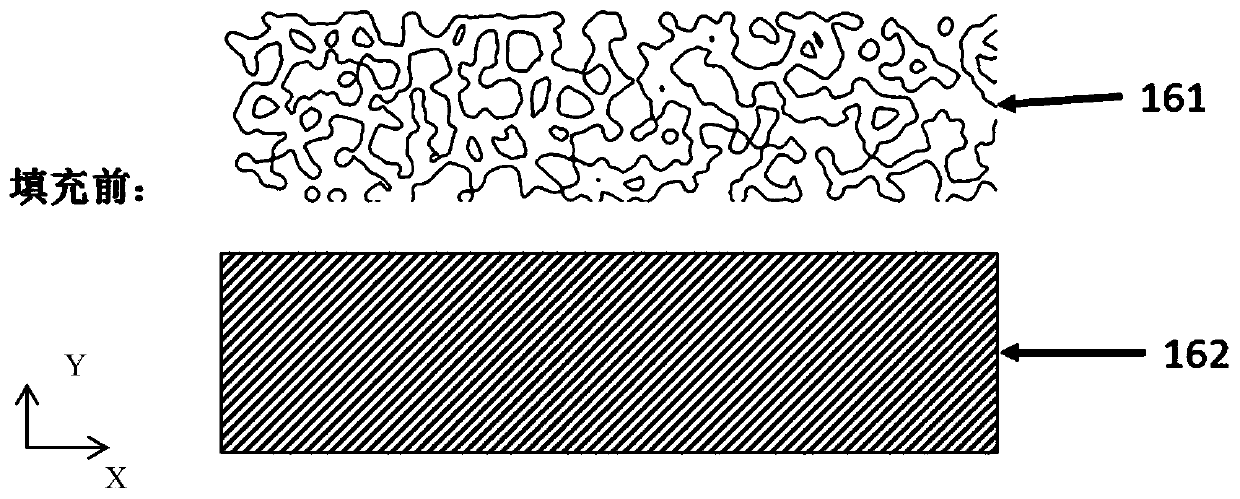

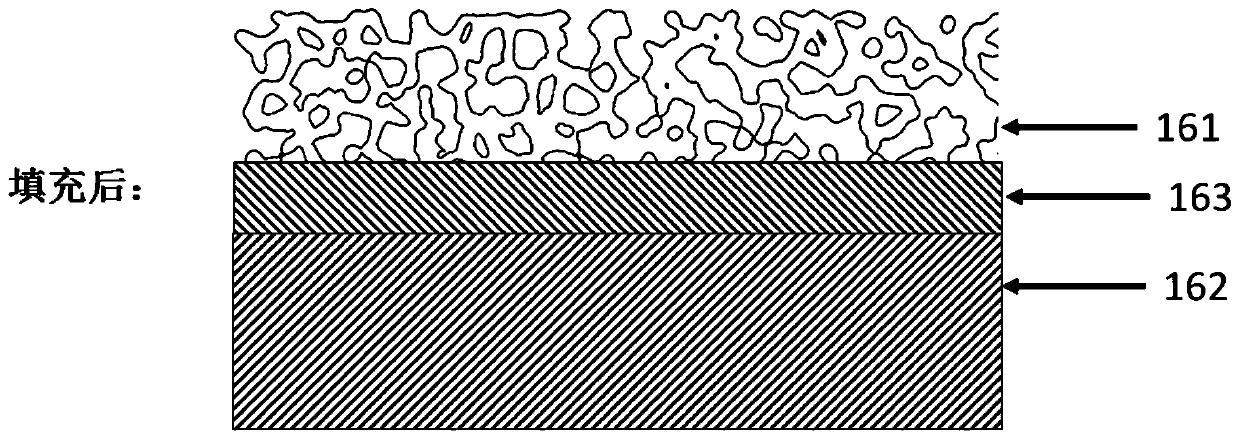

[0258] Figure 2a and Figure 2b They are schematic diagrams of the structure of the porous surface structure and the substrate before filling and after filling in Example 1, respectively. Figure 2a The positive direction of the X-axis shown in , represents the right, the negative direction of the X-axis represents the left, the positive direction of the Y-axis represents the top, and the negative direction of the Y-axis represents the bottom. To describe the technical solution of the present invention, the above-mentioned orientation regulations are only used to represent illustrations, and do not affect the orientation in practical applications.

[0259] The base 162 is solid, which is conducive to the overall strength of the connection structure, such as Figure 2a and Figure 2bshown. Alternatively, the substrate is another porous structure and the porosity of the substrate is less than that of the porous surface structure (not shown). The base 162 can be made of met...

Embodiment 1

[0262] With regard to Embodiment 1, the above-mentioned scheme has defects: due to the formation of some multi-directional penetration, regular or irregular pores between the supports (or beams) of the porous surface structure 161, when the polymer material 163 is injected to fill the porous surface structure During the pore process of 161 , part of the polymer material is likely to permeate until it exceeds the top of the porous surface structure 161 , which will greatly affect the appearance and other performance (such as bone ingrowth) of the surface of the porous surface structure 161 .

[0263] In order to solve the above problems, the connection structure in the second embodiment is provided with a porous surface structure 171 in the high-porosity region (the porous surface structure 171 is also referred to as the first porous structure 171), and a second porous structure in the low-porosity region. Structure 172 (as a spacer layer) and substrate 173, the second porous st...

Embodiment 3

[0270] As a modification of Embodiment 2, such as Figure 4a and Figure 4b As shown in combination, in the third embodiment, the non-porous spacer plate 182 with a solid structure is used to replace the second porous structure 172 in the low-porosity region in the second embodiment above, that is, when the second porous structure in the second embodiment When the porosity is zero, it becomes the non-porous spacer 182 in the third embodiment. Similarly, the porous surface structure 181 in the third embodiment includes many struts (or beams) arranged in a staggered manner, and some multi-directional, regular or irregular pores are formed between these struts (or beams).

[0271] In some examples, the non-porous spacer plate 182 may be disposed at any cross-sectional position between the top and the bottom of the porous surface structure 181 .

[0272] Exemplarily, the direction in which the non-porous spacer plate 182 is embedded into the porous surface structure 181 (for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com