Polymer dispersed liquid crystal material and method for preparing liquid crystal films from same

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of loss of scattered light, inability to store for a long time, polymer aggregation, etc., and achieve good light transmission effect, uniform distribution, low Effect of driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] TMPTMP 32 parts by weight

[0052] EOEOEA 33 parts by weight

[0053] CN985B88 30 parts by weight

[0054] I-184 5 parts by weight

[0055] Z-1 1 parts by weight

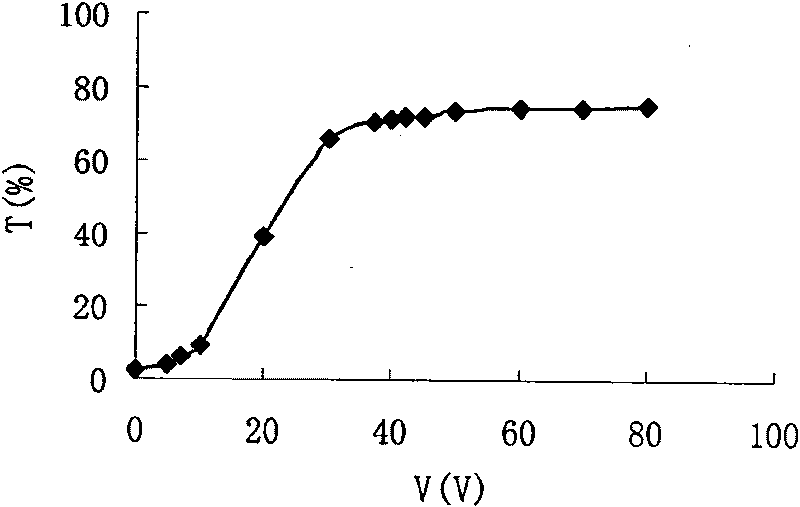

[0056] Mix the above-mentioned components uniformly to prepare a composition for preparing polymer-dispersed liquid crystals; then mix the composition with liquid crystal LC-001 to form a polymer-dispersed liquid crystal mixture, and obtain the liquid crystal containing liquid crystal of the present invention for preparing A mixture of polymer dispersed liquid crystal films. The parts by weight of the composition and the liquid crystal in the mixture are 100 parts respectively.

[0057] When manufacturing the above mixture, a small amount of SPACER can also be added to the prepared polymer-dispersed liquid crystal composition together with the liquid crystal, and the particle size of the SPACER is 20 microns. Of course, it is also possible to add SPACER and mix evenly before producing the PDLC film after...

Embodiment 2

[0060] TMPTMP 20 parts by weight

[0061] EOEOEA 45 parts by weight

[0062] CN985B88 32 parts by weight

[0063] I-184 3 parts by weight

[0064] Z-1 1 parts by weight

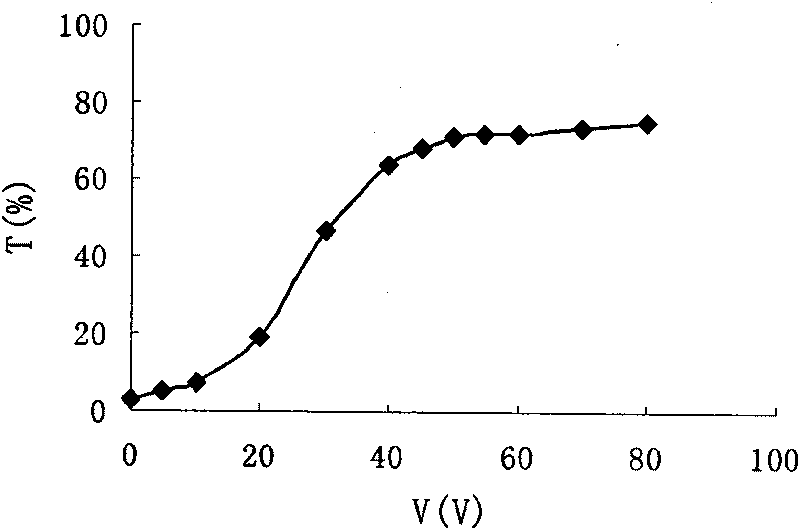

[0065] The above-mentioned components are uniformly mixed to prepare a polymer-dispersed liquid crystal composition. Mix this composition with liquid crystal LC-001 and a small amount of SPACER to make a polymer-dispersed liquid crystal mixture. In the mixture, the weight parts of the composition and the liquid crystal are respectively 100 parts and 95 parts, and the particle diameter of the SPACER is 20 microns.

[0066] The above-mentioned liquid crystal-containing mixture used for preparing polymer-dispersed liquid crystals is uniformly coated between two pieces of ITO conductive glass, and pressed evenly with a roller. Use a strength of 8mw / cm at room temperature 2 10 minutes of ultraviolet light with a wavelength of 365nm is irradiated to obtain a cured PDLC film. The thickness of the PDLC film is...

Embodiment 3

[0068] TMPTMP 25 parts by weight

[0069] EOEOEA 40 parts by weight

[0070] CN985B88 30 parts by weight

[0071] I-184 7 parts by weight

[0072] Z-1 1 parts by weight

[0073] The above-mentioned components are uniformly mixed to prepare a polymer-dispersed liquid crystal composition. Mix this composition with liquid crystal LC-001 and a small amount of SPACER to make a polymer-dispersed liquid crystal mixture. In the mixture, the weight parts of the composition and the liquid crystal are 100 parts and 96 parts respectively, and the particle diameter of the SPACER is 20 microns.

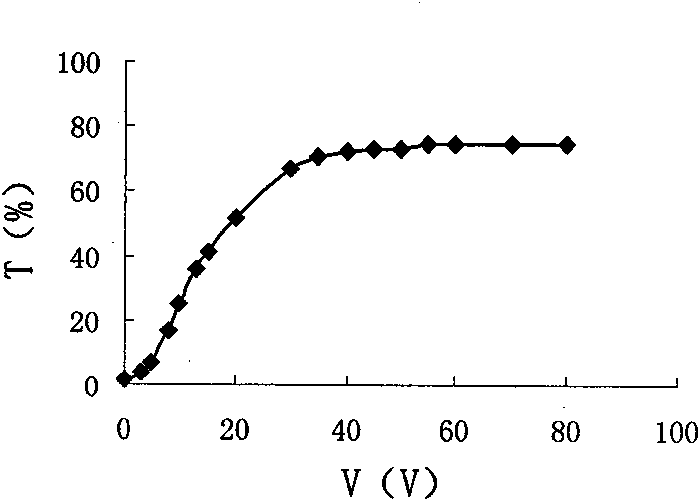

[0074] Spread the above-mentioned mixture containing liquid crystal and SPACER evenly between two pieces of ITO conductive glass, and press it evenly with a roller. Use a strength of 15mw / cm at room temperature 2 1. UV light with a wavelength of 365nm was irradiated for 6 minutes to obtain a cured PDLC film. The thickness of the PDLC film is 20 micrometers, and the driving voltage is 40V. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com