Liquid antioxidant and its preparing method

An antioxidant and liquid technology, applied in the field of antioxidants and their preparation, can solve the problems of high volatility and low molecular weight, and achieve the effects of strong antioxidant properties, improved production efficiency, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

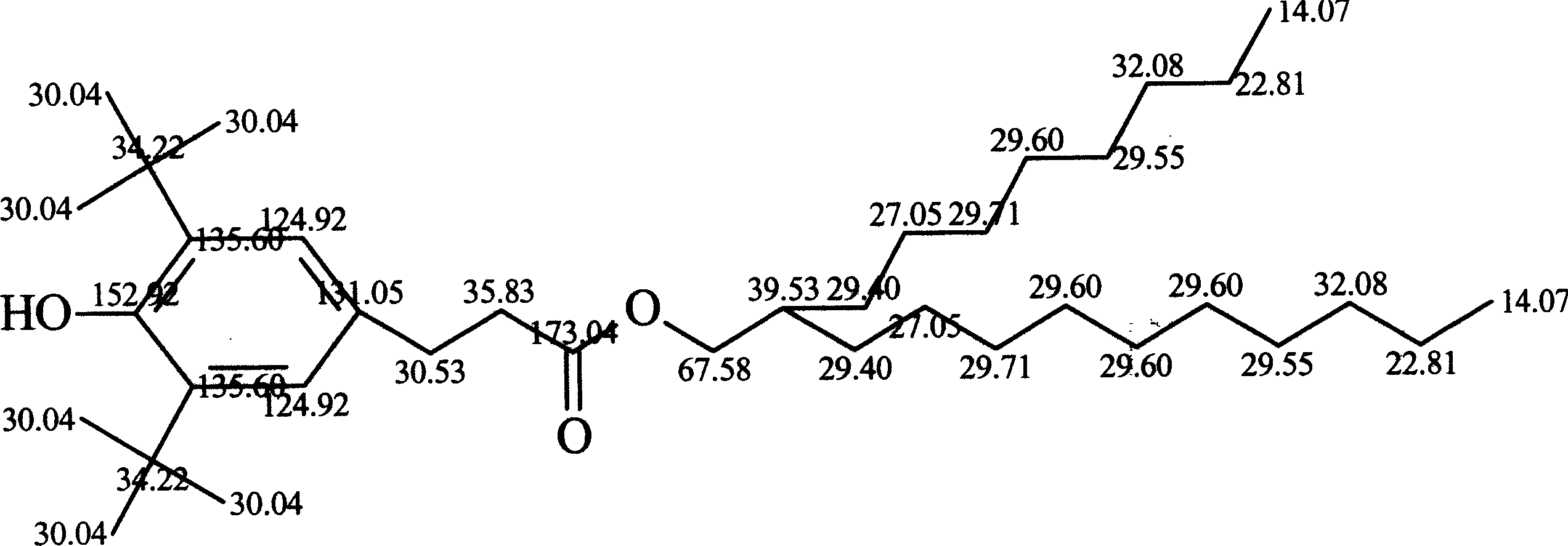

Image

Examples

Embodiment 1

[0025] This example is the preparation of Guerbet alcohol.

[0026] 500g of decanol is put into the reaction flask, which is equipped with a mechanical stirrer, a thermometer, a water separator, and a condenser. Add 15 grams of KOH and 1.0 grams of nickel, heat to 250°C as soon as possible under full stirring, and reflux for four hours to remove the water generated during the reaction, cool and filter, and distill to obtain C20 Grignard alcohol.

[0027] C24 Grignard alcohol and C16 Grignard alcohol that can be prepared in the same way, but the reaction raw materials are changed to dodecyl alcohol and octanol.

Embodiment 2

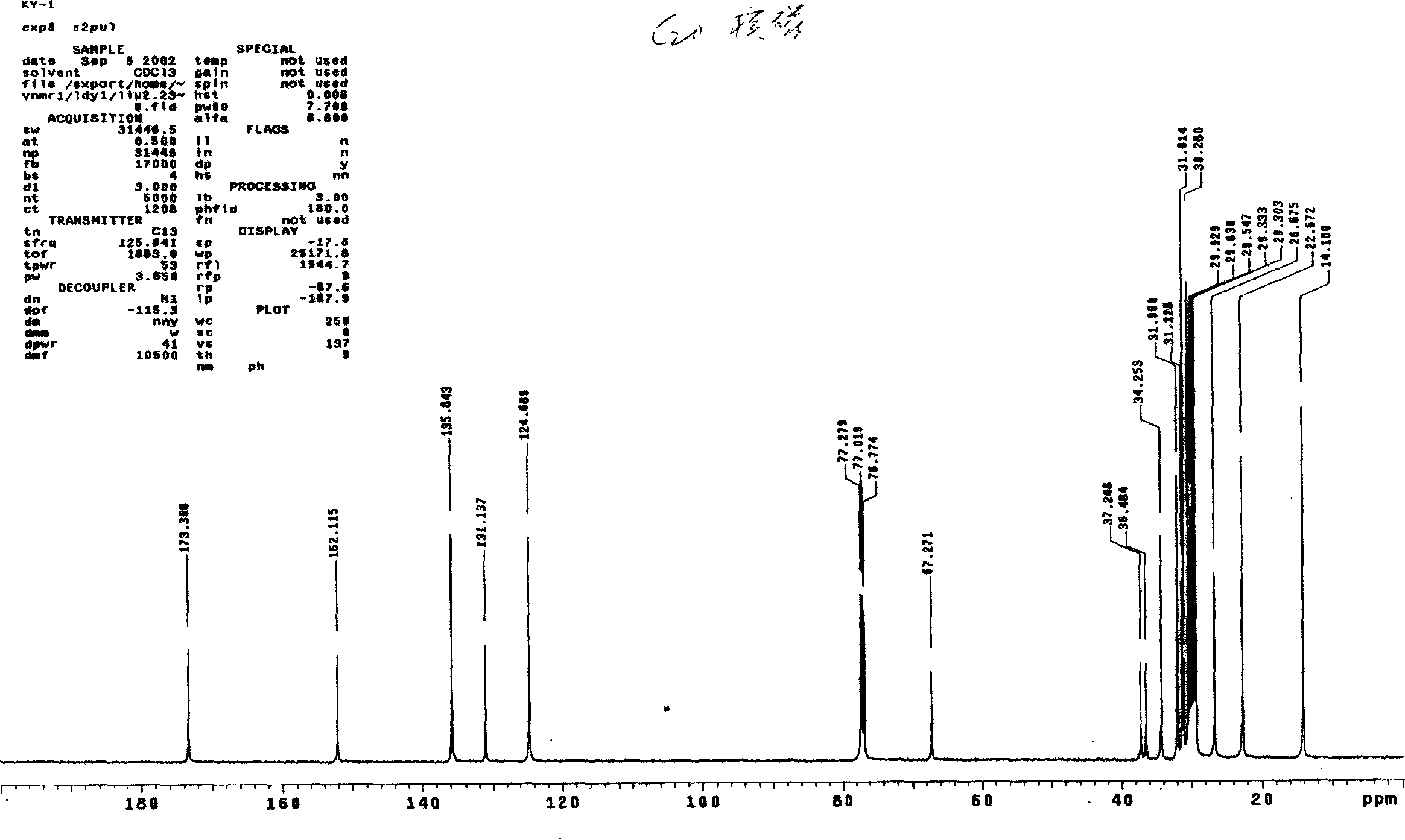

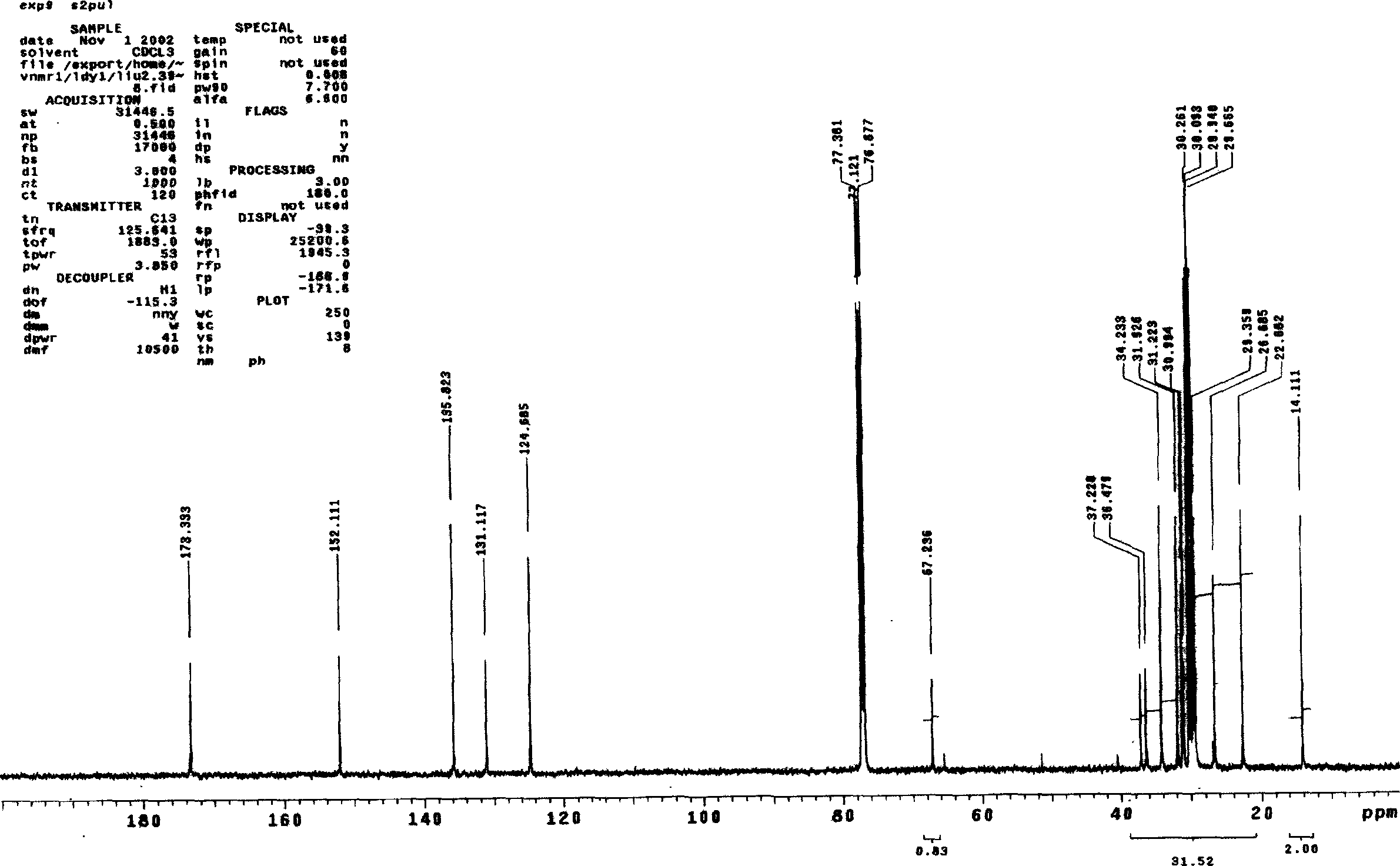

[0029] 0.5 moles of C20 Grignard alcohol 149g and 0.5 moles of β-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate 146g prepared in Example 1 were placed in a 500ml four-necked reaction flask, The reaction bottle is equipped with a mechanical stirrer, a thermometer, a water separator, and a condenser. Add 1.25 g of 0.15 mole lithium hydroxide, heat, depressurize to 0.085 MPa, temperature is 160°C, react for 4.2 hours, heat up to 240°C, distill under reduced pressure to remove unreacted raw materials, cool to room temperature, filter to obtain light yellow liquid Product 259.32g, yield 92.95%. The product is used for chromatography-mass spectrometry, and the unreacted β-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate content is determined to be 5.5%, the product is 93.0%, the product molecular weight is 558, and the mass spectrum molecular ion peak It is 558.7, and the relative abundance is 37%, (the instrument is American TRACEMS mass spectrometer, quadrupole mass s...

Embodiment 3

[0031] 0.5 moles of C20 Grignard alcohol 149g and 0.7 moles of β-(3,5-di-tert-butyl-4-hydroxyphenyl) methyl propionate 146g prepared in Example 1 were placed in the same reaction as in Example 2 1.25 g of titanium tetraisopropoxide was added to the bottle, heated, depressurized to 0.087 MPa, and reacted for 3.6 hours at a temperature of 160°C. Cool down to 110°C, add 10ml of water, stir, slowly heat up to reflux to 140°C, remove water, heat up to 240°C, distill under reduced pressure to remove unreacted raw materials, cool to room temperature, filter to obtain 251.6g of light yellow liquid product, and collect The rate is 90.18%. The product content was determined to be 95.0% by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com