Squeezable Assembly for Pasty Products

a technology of pasty products and assembly parts, which is applied in the direction of packaging foodstuffs, packaged goods, pliable tubular containers, etc., can solve the problems of limit the possibilities of playing with low molecular components, and achieve the effect of high softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

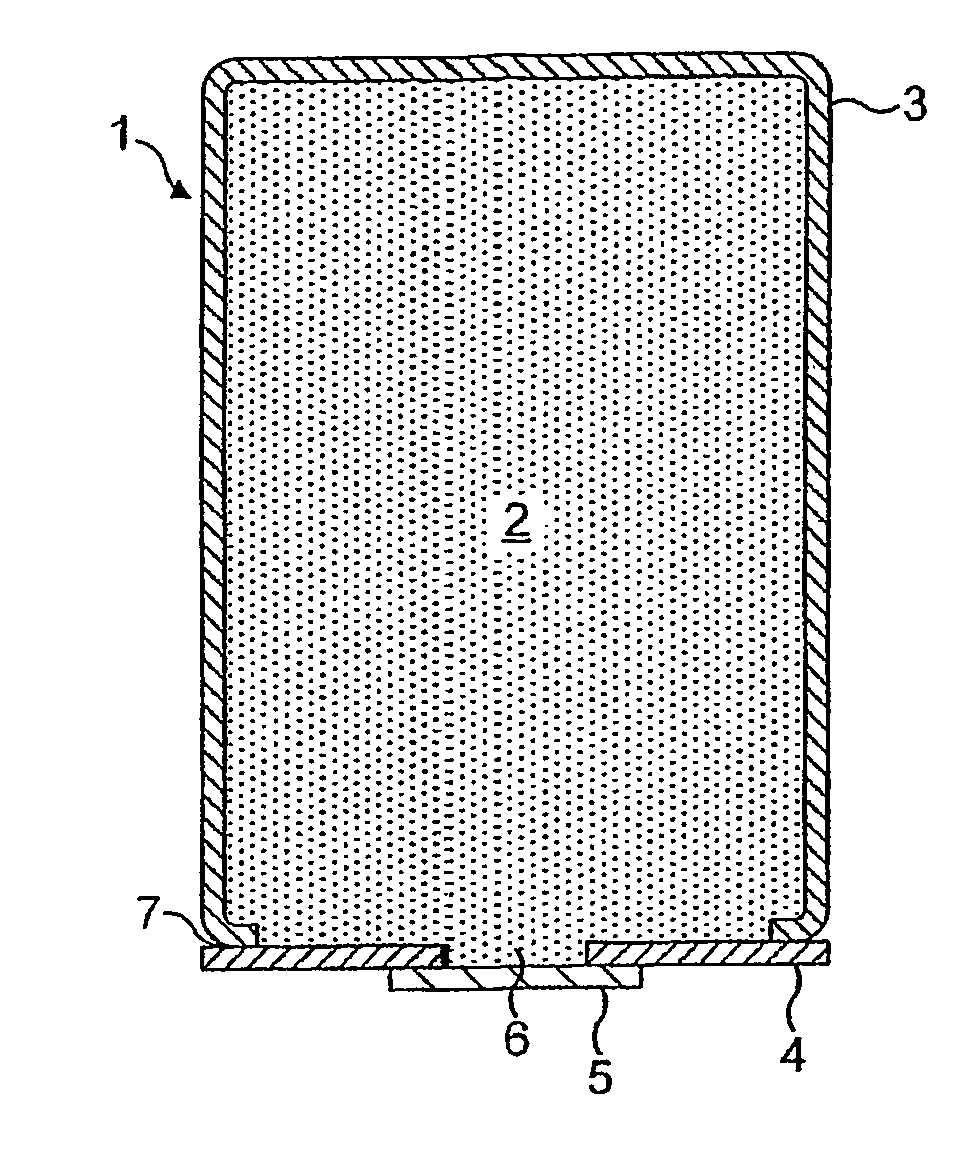

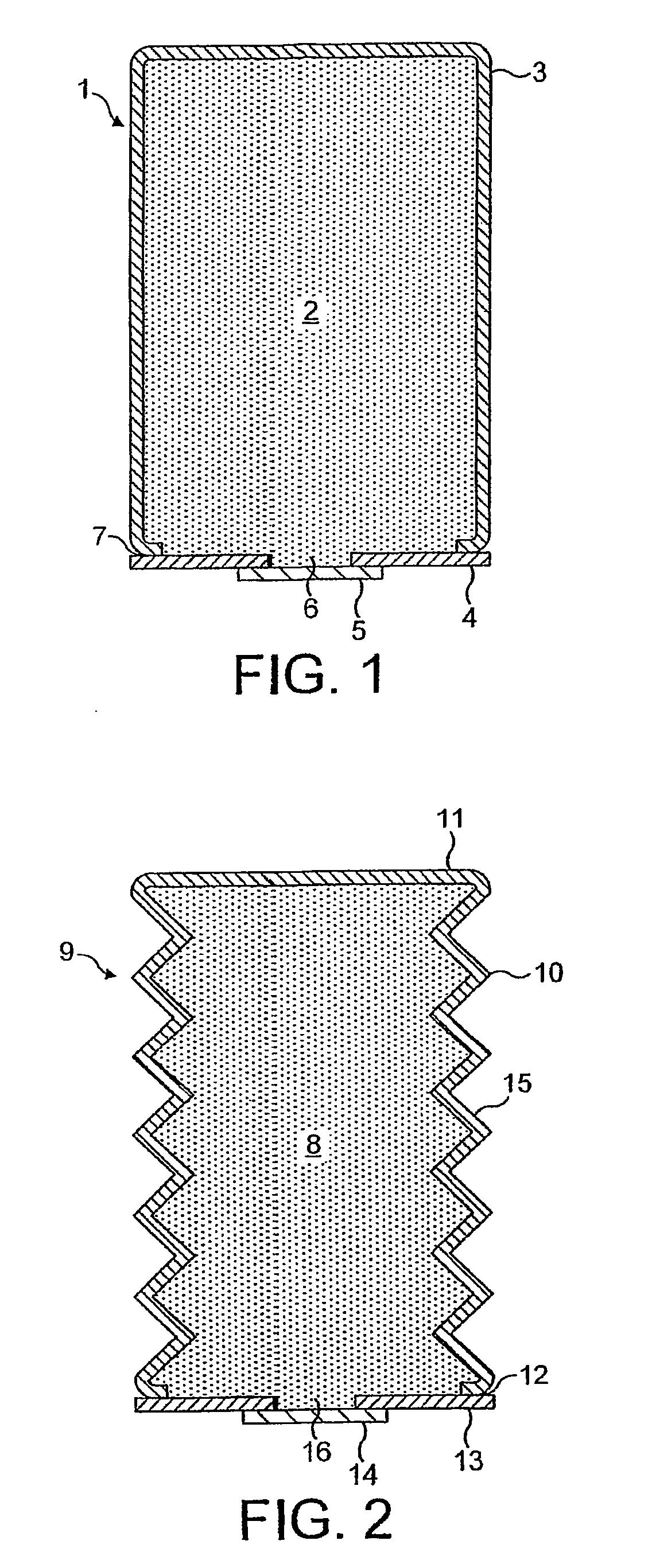

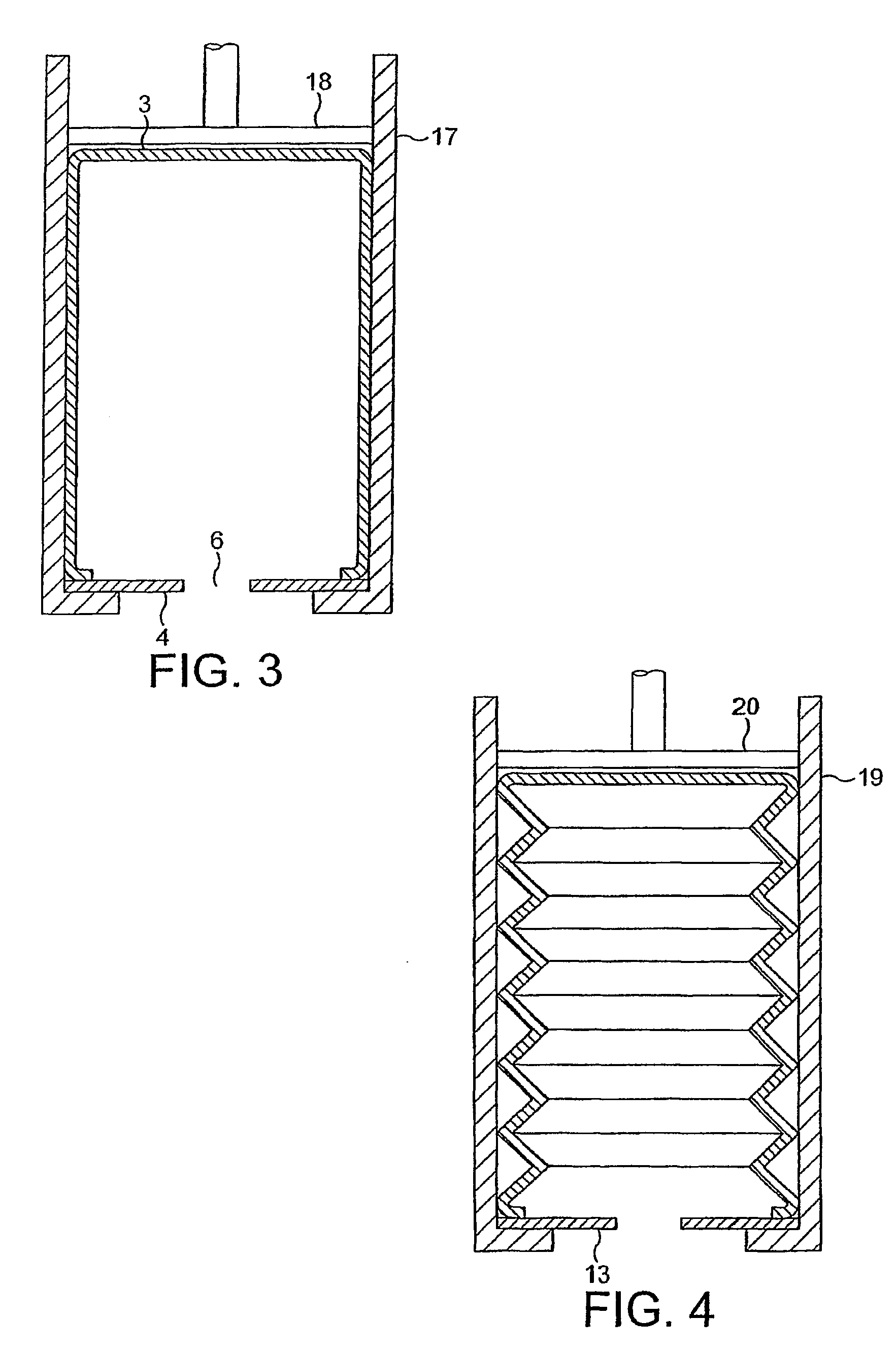

Image

Examples

examples 1 to 4

[0069] Ice confections are formulated and produced according to the following processing conditions:

[0070] Vegetable fibre when used is mixed with some sugar or predispersed in some water at temperature of 45° C. and added with all the powdery ingredients to liquid ingredients and glycerol in an agitated mixing tank. Once all ingredients have been thoroughly blended together, the mixture was heated at 65° C. for 20 min. in order to hydrate the hydrocolloids.

[0071] For pasteurisation, the mixture is then heated to a temperature of 87° C. for 24 s. to achieve satisfactory treatment to confrm public health requirements and also avoiding as much as possible any significant denaturation of proteins.

[0072] The mixture is then subjected to an homogenisation stage to reduce the dimensions of the fat droplets, by homogenising the mixture at a pressure of 120 to 160 bar, at a temperature of 70 to 85° C. The homogenised mix is rapidly cooled to chill temperatures, typically 4° C. and then a...

example 5

Example 5, Comparative Example 5

Use of PEFA in the Presence of Freezing Point Depressing Sugars

[0077] The objective of these examples is to produce soft aerated frozen confections with freezing point depressing sugars showing texture and sensory attributes which are comparable to a conventional product made with conventional ingredients currently used in the aerated frozen dessert preparation.

[0078] To evaluate the remarkable properties of the emulsifier applied, various textural, microscopic and macroscopic tests may be carried out.

[0079] Standard heat shock: the samples initially stored at −30° C. are subjected, for 7 days, to temperature cycles of −8° C. / 12 h followed by −20° C. / 12 h. After 7 days of stabilisation at −30° C., the melting parameters are evaluated for these samples which were subjected to a heat shock.

[0080] We were surprised to find that the use of polyol esters of fatty acids (PEFA), preferable propylene glycol monostearate (PGMS) alone or in combination wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com