Super-hydrophobic glass coating and preparation method thereof

A glass coating and super-hydrophobic technology, which is applied in the field of super-hydrophobic glass coating and its preparation, can solve the problems of not being obvious enough, the coating is not durable, etc., and achieve the effect of improving anti-fingerprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

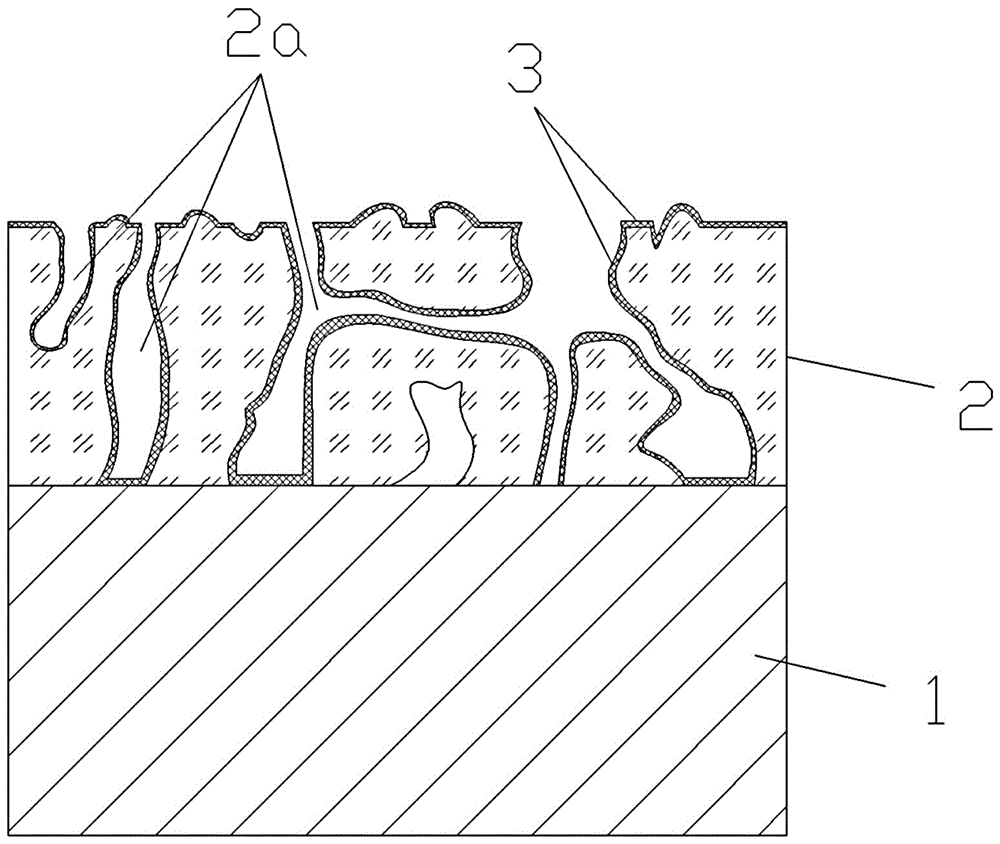

[0024] Such as figure 1 As shown, the present invention provides a superhydrophobic glass coating and a preparation method thereof, comprising a nanoporous glass membrane 2 and a low surface energy hydrophobic membrane 3 attached to the surface of the glass 1 in sequence from the inside to the outside, and the thickness of the nanoporous glass membrane 2 150-1000nm, the pore size of the nanoporous glass membrane 2 is 1-100nm; the low-surface-energy hydrophobic membrane 3 is siloxane or fluorinated siloxane with a thickness of 1-20nm, and the surface energy of the low-surface-energy hydrophobic membrane 3 is less than 40mN / m, siloxane or fluorinated siloxane is attached to the outer surface of the nanoporous glass membrane 2 and the inner wall of the nanoporous glass membrane pores 2a; preferably, the nanoporous glass membrane 2 contains mole fraction of 80-100% Amorphous silicon oxide, 0-12% boron oxide and 0-8% sodium oxide.

[0025] On the basis of the above, the nanoporous...

Embodiment 1

[0029] A preparation method for superhydrophobic glass coating, comprising the following steps:

[0030] S1. Use ethanol and deionized water to ultrasonically clean the aluminosilicate glass substrate in sequence for 10 minutes, and then treat the glass substrate with a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide at a volume ratio of 3:1 for 15 minutes to make the glass substrate 1 clean and easy to clean. deposition and bonding surfaces;

[0031] S2. Use the vacuum radio frequency magnetron sputtering process to coat the glass film on the glass substrate. The sputtering target is composed of 65-78% silicon oxide, 9-14% sodium oxide and 18-24% boron oxide. Mixed target material; before sputtering, vacuum to 4×10 -4 Pa, the glass substrate is heated to 350°C, the argon flow rate is 50sccm, the sputtering power is 450W, and the sputtering time is 15min;

[0032] S3, heat-treat the obtained glass film in a box-type resistance furnace at 500° C. fo...

Embodiment 2

[0037] A preparation method for superhydrophobic glass coating, comprising the following steps:

[0038] S1. Use ethanol and deionized water to ultrasonically clean the quartz glass substrate in sequence for 15 minutes, and then treat the glass substrate with a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide at a volume ratio of 3:1 for 20 minutes to make the glass substrate 1 clean, easy to deposit and bond. fit surface;

[0039] S2. Use the vacuum radio frequency magnetron sputtering process to coat the glass film on the glass substrate. The sputtering target is composed of 65-78% silicon oxide, 9-14% sodium oxide and 18-24% boron oxide. Mixed target material; before sputtering, vacuum to 4×10-4 Pa, the glass substrate is heated to 200°C, the flow rate of argon gas is 40sccm, the sputtering power is 400W, and the sputtering time is 10min;

[0040] S3, heat-treating the obtained glass film in a box-type resistance furnace at 700° C. for 3 hours, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com