A kind of modified af coating material and its preparation method and application

A coating and modification technology, which is applied in metal material coating process, coating, sputtering coating, etc., can solve problems such as not being able to meet market demand, achieve good waterproof, simple preparation process, and improve waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

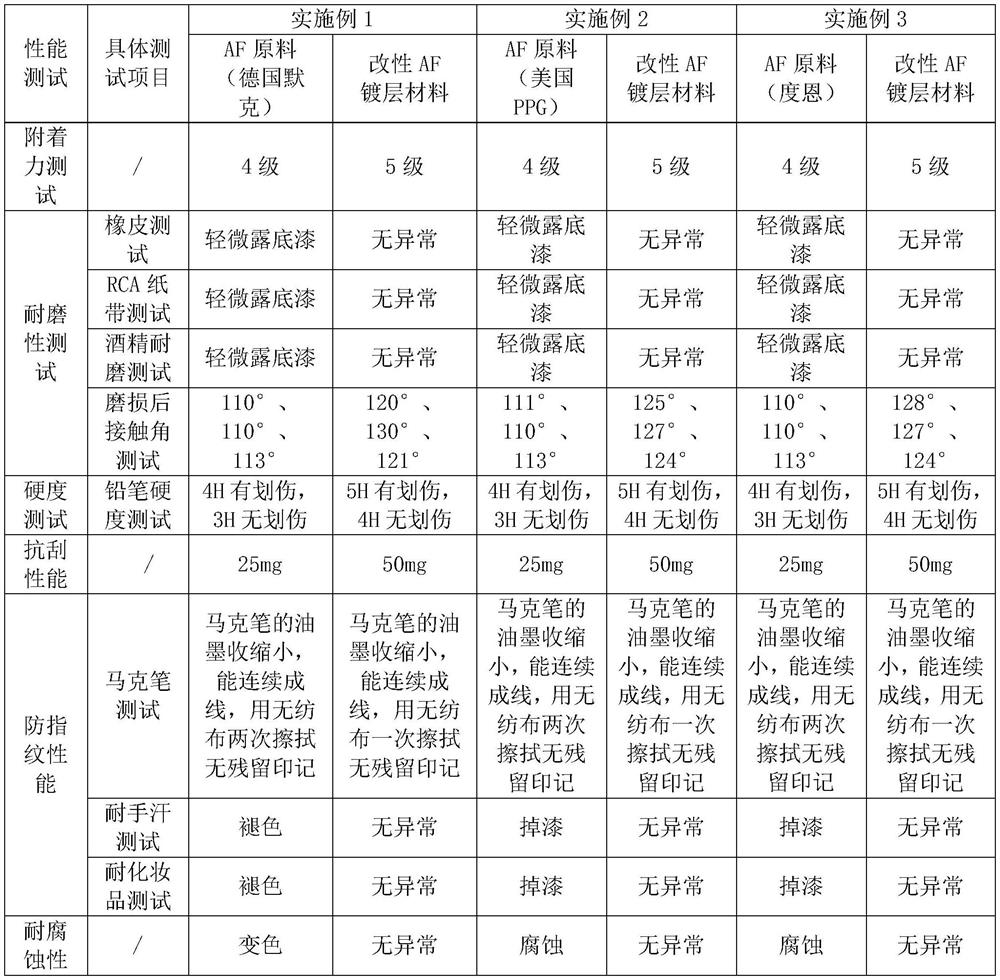

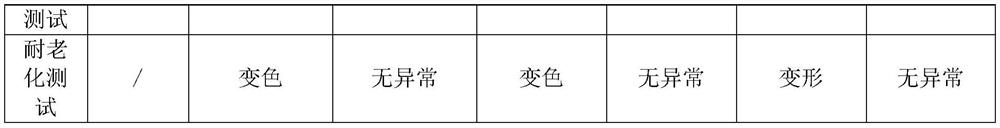

Embodiment 1

[0040] A modified AF coating material, comprising AF raw material and a modifier, the mass ratio of the AF raw material to the modifier is 20:2.5.

[0041] The AF raw material comes from Merck WR6 series coating film material in Germany. WR6 is specially designed for the production of hydrophobic and oleophobic coatings to meet the mature anti-fingerprint, anti-smudge and easy-to-clean surface treatment technology market demand in today's touch screen market , using the method of vacuum evaporation, WR6 can significantly reduce the adhesion of dust and fingerprints on the sensing surface of the touch screen, thus providing an excellent ease of operation.

[0042] The modifying agent includes fatty acid lead salt, methyl hexahydrophthalic anhydride, 4-nonylbenzene powder, nano-layer increasing agent and butylphenol, and the modifying agent is based on the mass ratio of fatty acid lead salt: methyl Hexahydrophthalic anhydride: 4-nonylbenzene powder: nano-layer enhancer: butylphe...

Embodiment 2

[0050] A modified AF coating material comprises AF raw materials and modifiers, and the mass ratio of the AF raw materials to the modifiers is 20:3.

[0051] The AF raw material comes from the EC300X series of PPG in the United States.

[0052] The modifying agent includes fatty acid lead salt, methyl hexahydrophthalic anhydride, 4-nonylbenzene powder, nano-layer increasing agent and butylphenol, and the modifying agent is based on the mass ratio of fatty acid lead salt: methyl Hexahydrophthalic anhydride: 4-nonylbenzene powder: 4-aminobiphenyl: butylphenol = 1:1:1:1:2.

[0053] The nano-layer increasing agent is 4-aminobiphenyl.

[0054] The butylphenol is a mixture of di-tert-butylphenol and sec-butylphenol with a mass ratio of 1:1.

[0055] The modifier also includes bicyclooctane, dioxane, di-n-octyl-bis(2-ethylhexyl mercaptoacetate) tin.

[0056] The bicyclooctane is a combination of cis-isomerization and trans-isomerization, and the mass of the bicyclooctane accounts ...

Embodiment 3

[0060] A modified AF coating material, comprising AF raw material and modifier, the mass ratio of the AF raw material to the modifier is 20:3.5.

[0061] The AF raw material comes from Duen superhard waterproof membrane SH-HT9080.

[0062] The modifying agent includes fatty acid lead salt, methyl hexahydrophthalic anhydride, 4-nonylbenzene powder, nano-layer increasing agent and butylphenol, and the modifying agent is based on the mass ratio of fatty acid lead salt: methyl Hexahydrophthalic anhydride: 4-nonylbenzene powder: nano-layer enhancer: butylphenol=1:1:1:1:2.

[0063] The nano-layer increasing agent is 4-aminobiphenyl.

[0064] The butylphenol is a mixture of di-tert-butylphenol and sec-butylphenol with a mass ratio of 1:1.

[0065] The modifier also includes bicyclooctane, dioxane, di-n-octyl-bis(2-ethylhexyl mercaptoacetate) tin.

[0066] The bicyclooctane is a combination of cis-isomerization and trans-isomerization, and the mass of the bicyclooctane accounts for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com