A kind of film material for eye protection computer screen

A computer screen and film material technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problem of low blue light and ultraviolet absorption and transmittance, reduce harmful blue light transmittance, object color display distortion, etc. problem, to achieve the effect of significant eye protection, low price, and reduced transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

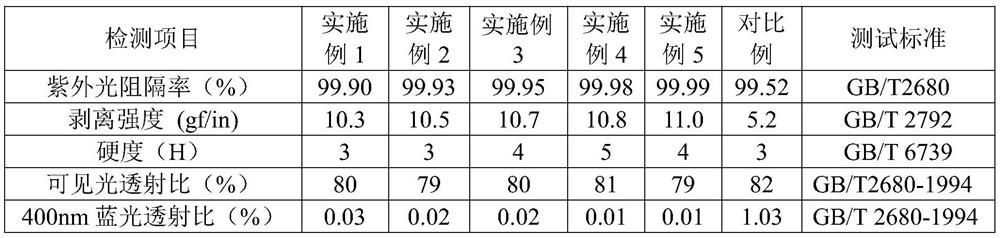

Examples

Embodiment 1

[0035] A film material for eye-protecting computer screens, comprising a wear-resistant layer, a blue light absorbing layer, and a release protective film layer arranged sequentially from top to bottom, between the wear-resistant layer and the blue light absorbing layer, the blue light absorbing layer and the release The protective film layers are respectively connected by independent transparent adhesive layers; the blue light absorbing layer is made of monomer tetrakis [4-(4'-carboxyphenyl) phenyl] ethylene, acrylonitrile, ethylene carbonate , 1-allyl-3-vinylimidazolium chloride salt polymerization formed by addition polymer as substrate, and 2,9-dimethyl-4,7-diphenyl-1,10-phenanthrolinesulfonic acid di After ion exchange of sodium salt, it is prepared by adding p-cyanoaniline modified 1,3,5-tris(4-carboxyphenylethynyl)benzene, Tb-Eu-Re-O, and silane coupling agent KH560 The wear-resistant layer is prepared by blending polycondensation products of transparent nylon, 1,3-adam...

Embodiment 2

[0048] A film material for eye-protecting computer screens, comprising a wear-resistant layer, a blue light absorbing layer, and a release protective film layer arranged sequentially from top to bottom, between the wear-resistant layer and the blue light absorbing layer, the blue light absorbing layer and the release The protective film layers are respectively connected by independent transparent adhesive layers; the blue light absorbing layer is made of monomer tetrakis [4-(4'-carboxyphenyl) phenyl] ethylene, acrylonitrile, ethylene carbonate , 1-allyl-3-vinylimidazolium chloride salt polymerization formed by addition polymer as substrate, and 2,9-dimethyl-4,7-diphenyl-1,10-phenanthrolinesulfonic acid di After ion exchange of sodium salt, it is prepared by adding p-cyanoaniline modified 1,3,5-tris(4-carboxyphenylethynyl)benzene, Tb-Eu-Re-O, and silane coupling agent KH560 The wear-resistant layer is prepared by blending polycondensation products of transparent nylon, 1,3-adam...

Embodiment 3

[0061] A film material for eye-protecting computer screens, comprising a wear-resistant layer, a blue light absorbing layer, and a release protective film layer arranged sequentially from top to bottom, between the wear-resistant layer and the blue light absorbing layer, the blue light absorbing layer and the release The protective film layers are respectively connected by independent transparent adhesive layers; the blue light absorbing layer is made of monomer tetrakis [4-(4'-carboxyphenyl) phenyl] ethylene, acrylonitrile, ethylene carbonate , 1-allyl-3-vinylimidazolium chloride salt polymerization formed by addition polymer as substrate, and 2,9-dimethyl-4,7-diphenyl-1,10-phenanthrolinesulfonic acid di It is prepared by adding p-cyanoaniline modified 1,3,5-tris(4-carboxyphenylethynyl)benzene, Tb-Eu-Re-O and silane coupling agent KH560 after ion exchange of sodium salt The wear-resistant layer is prepared by blending polycondensation products of transparent nylon, 1,3-adaman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com