Intelligent temperature-control energy-saving composite coating film

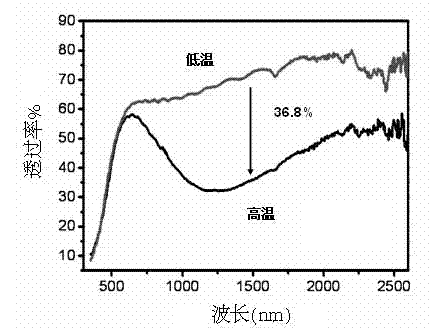

An intelligent temperature control and composite sticking technology, applied in the direction of film/flake adhesives, coatings, layered products, etc., can solve the problems of destroying the vanadium dioxide structure, and no modification method is proposed, and achieve the preparation process. Innovation, improved chemical stability and dispersion, effect of changing surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

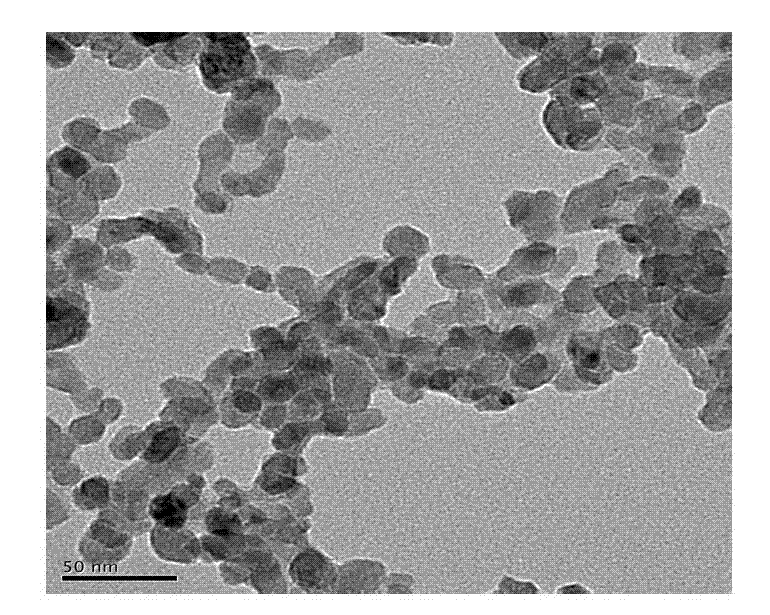

[0051] In the preparation method of the vanadium dioxide composite powder of the present invention, comprising, the vanadium dioxide nano-powder is dispersed in the dispersing medium, obtains the operation of mixture A; The process of organically modifying the organic modifier of long-chain molecules on the surface of vanadium oxide powder, stirring until fully mixed to obtain mixture B; drying the mixture B to obtain organically modified vanadium dioxide composite powder.

[0052] The preparation method of the above-mentioned vanadium dioxide composite powder, specifically, the vanadium dioxide powder with a weight percentage content of 1-50% and the dispersion medium of 50-99% can be stirred at a high speed to disperse and mix, and then ultrasonically dispersed to obtain a mixture, Then add dispersing aid and organic modifier to the mixture, stir at a constant temperature of 0-200°C, disperse by means of ultrasound, sand mill or ball mill, centrifuge and precipitate, and vacu...

Embodiment 1

[0071] (1) Surface organic modification of vanadium dioxide nanopowder:

[0072] Take the mass of each component as follows:

[0073] Vanadium dioxide nanopowder (doped with tungsten, particle size 20-100nm), 20g

[0074] Ethanol (dispersion medium), 80g

[0075] Silane coupling agent (containing polyvinyl alcohol group, organic modifier), 1g

[0076] Polyvinylpyrrolidone (dispersion aid), 0.05g;

[0077] First, the vanadium dioxide nano-powder and the dispersion medium were stirred and dispersed at a high speed of 1500rad / min for 30 minutes, and ultrasonically dispersed for 30 minutes, then the dispersion aid and silane coupling agent were added, and stirred at a constant temperature of 70°C on a high-speed mixer for 2 hours. Centrifuge again and dry in vacuum at 60°C to obtain a vanadium dioxide composite powder modified by an organosilicon coupling agent;

[0078] (2) Preparation of vanadium dioxide composite powder slurry:

[0079] Take the mass of each component as f...

Embodiment 2

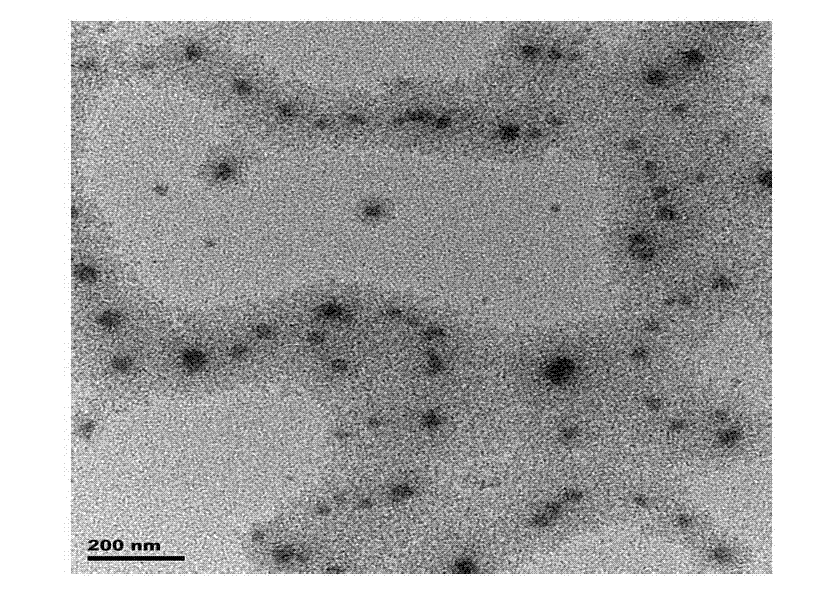

[0098] (1) Surface organic modification of vanadium dioxide nanopowder:

[0099] Take the mass of each component as follows:

[0100] Vanadium dioxide nanopowder (without doping, particle size 20-100nm), 10g

[0101] Ethanol (dispersion medium), 90g

[0102] Silane coupling agent (containing long chain alkylamine group, organic modifier), 1g

[0103] Polyvinyl alcohol (dispersion aid), 0.05g

[0104] First, the vanadium dioxide nanopowder and dispersion medium were dispersed under high-speed stirring at 1500rad / min for 30 minutes, and ultrasonically dispersed for 30 minutes, then the dispersing aid and stearic acid were added, and stirred at a constant temperature of 60°C on a high-speed mixer for 2 hours, and then Centrifugal precipitation, vacuum drying at 60°C to obtain vanadium dioxide nanocomposite powder modified with long-chain alkylamine groups;

[0105] (2) Preparation of vanadium dioxide composite powder slurry:

[0106] Take the mass of each component as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com