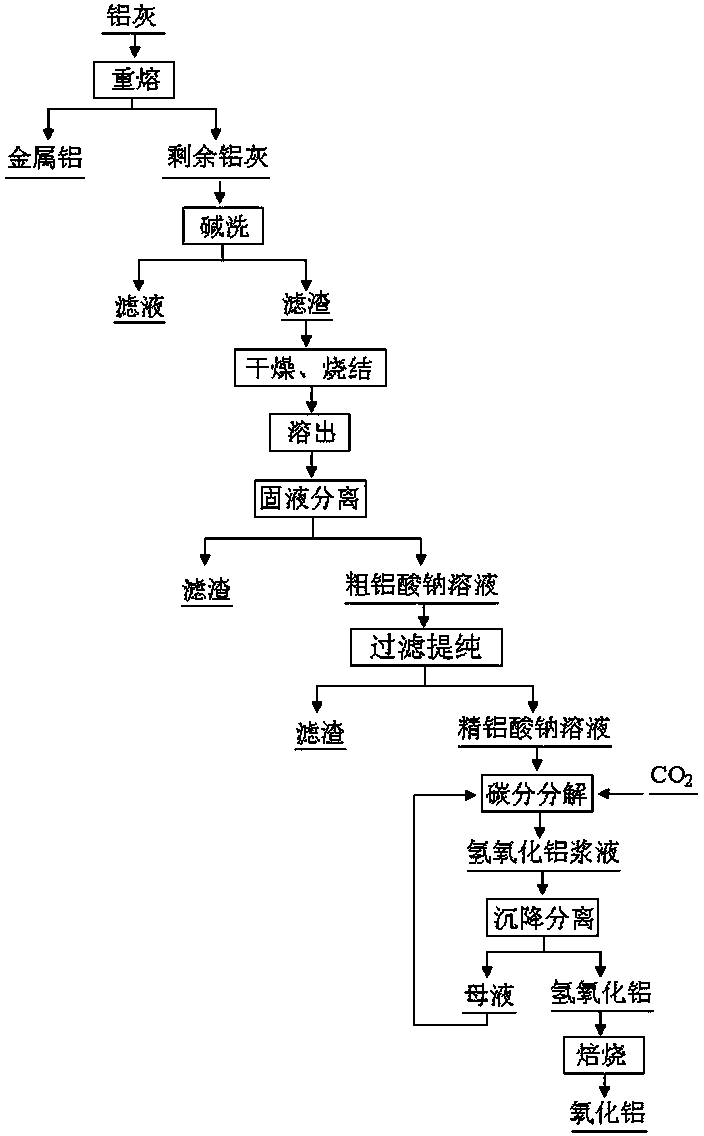

Method for harmlessly treating aluminum ash and preparing sandy alumina

A harmless treatment, aluminum oxide technology, applied in chemical instruments and methods, alkali metal aluminate/alumina/aluminum hydroxide preparation, alumina/hydroxide preparation, etc., can solve environmental pollution and waste of resources and other issues, to achieve the effect of less investment in equipment, high production efficiency, and high environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Put the aluminum ash into the aluminum ash high-speed processing system, and control the reaction temperature of the system to 900 o C. At the same time, the aluminum ash is continuously stirred, and the metal aluminum gathers in the collection device. After the aluminum ash is discharged from the high-speed processing system, it is directly introduced into a 5g / L sodium hydroxide solution, and the alkali washing temperature is controlled by adjusting the power of the microwave to 50 o c. After 2.5 hours, pour the aluminum ash after alkali washing into the filter equipment for filtration, and then pour the solid phase into the drying oven for drying until the water content is ≤14%. The dried aluminum ash and sodium carbonate are mixed in a ratio of 1:1, and then sodium hydroxide is added according to 20% of the mass of the aluminum ash, and placed in a rotary kiln. Keep the temperature of the kiln head of the rotary kiln at 1200 o C, the rotational speed of the rot...

Embodiment 2

[0032] Put the aluminum ash into the aluminum ash high-speed processing system, and control the reaction temperature of the system to 650 o C. At the same time, the aluminum ash is continuously stirred, and the metal aluminum gathers in the collection device. After the aluminum ash is discharged from the high-speed processing system, it is directly introduced into a 10 g / L sodium hydroxide solution, and the alkali cleaning temperature is controlled by adjusting the power of the microwave to 120 o c. After 1.5 hours, pour the aluminum ash after alkali washing into the filter equipment for filtration, and then pour the solid phase into the drying oven for drying. The dried aluminum ash and sodium carbonate are mixed in a ratio of 1:1, and then sodium hydroxide is added according to 10% of the mass of the aluminum ash, and placed in a rotary kiln. Keep the temperature of the rotary kiln at 750 o C, the rotational speed of the rotary kiln is 20 m / h. Finally, sintered clinker...

Embodiment 3

[0035] Put the aluminum ash into the aluminum ash high-speed processing system, and control the reaction temperature of the system to 800 o C. At the same time, the aluminum ash is continuously stirred, and the metal aluminum gathers in the collection device. After the aluminum ash is discharged from the high-speed processing system, it is directly introduced into the 8g / L sodium hydroxide solution, and the alkali washing temperature is controlled by adjusting the power of the microwave to 100 oc. After 2 hours, pour the aluminum ash after alkali washing into the filter equipment for filtration, and then pour the solid phase into the drying oven for drying. The dried aluminum ash and sodium carbonate are mixed according to the ratio of 1:1.8, and then sodium hydroxide is added according to 50% of the mass of the aluminum ash, and placed in a rotary kiln. Keep the temperature of the rotary kiln at 1100 o C, the rotational speed of the rotary kiln is 13m / h. Finally, sintere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com