Method of wrapping hollow glass bead by virtue of dye-sensitized nanometer ferric oxide

A technology of nanometer ferric oxide and hollow glass microspheres, which is applied in the fields of chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. In order to save raw materials, improve bonding fastness, and enhance photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

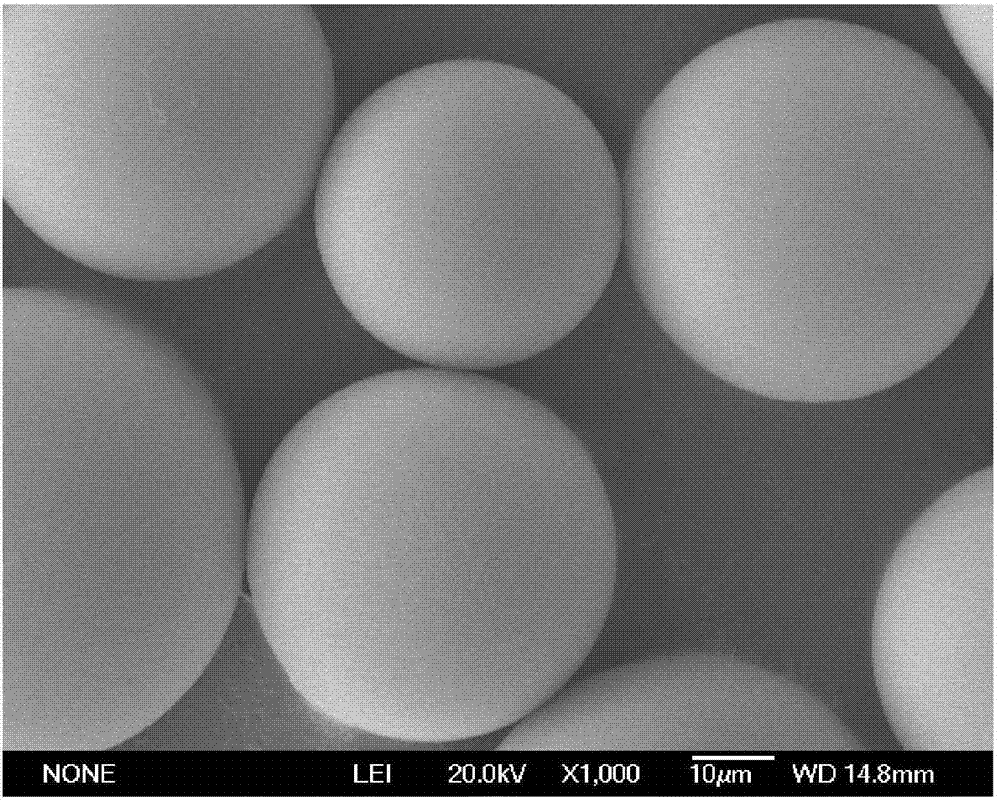

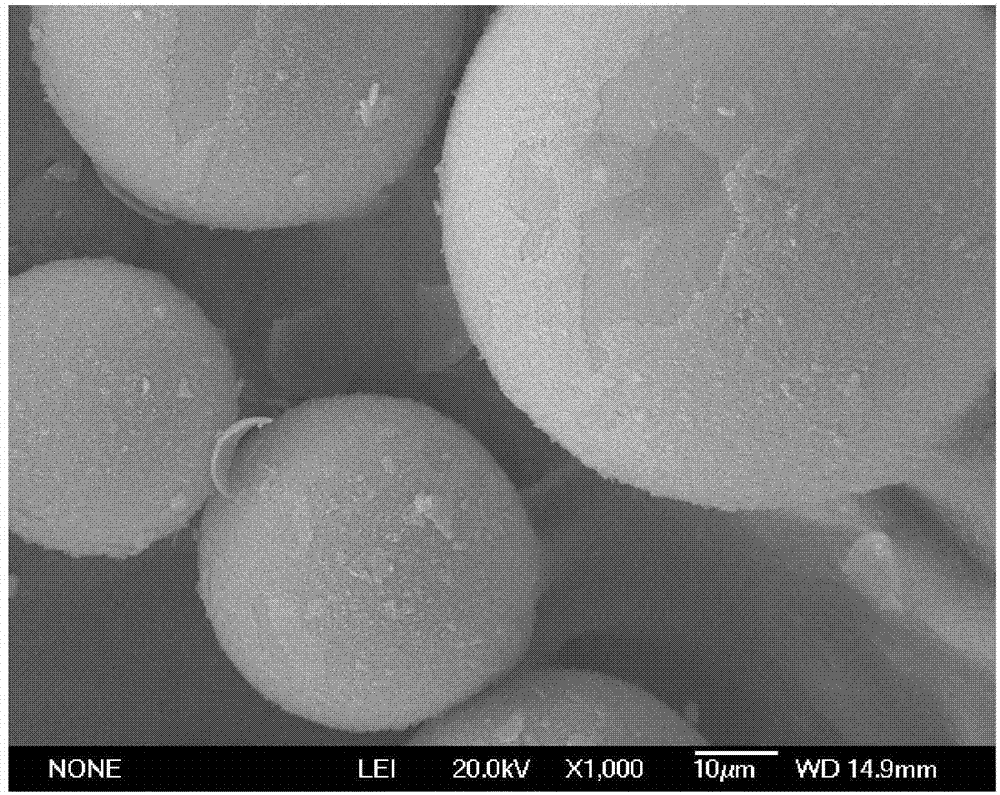

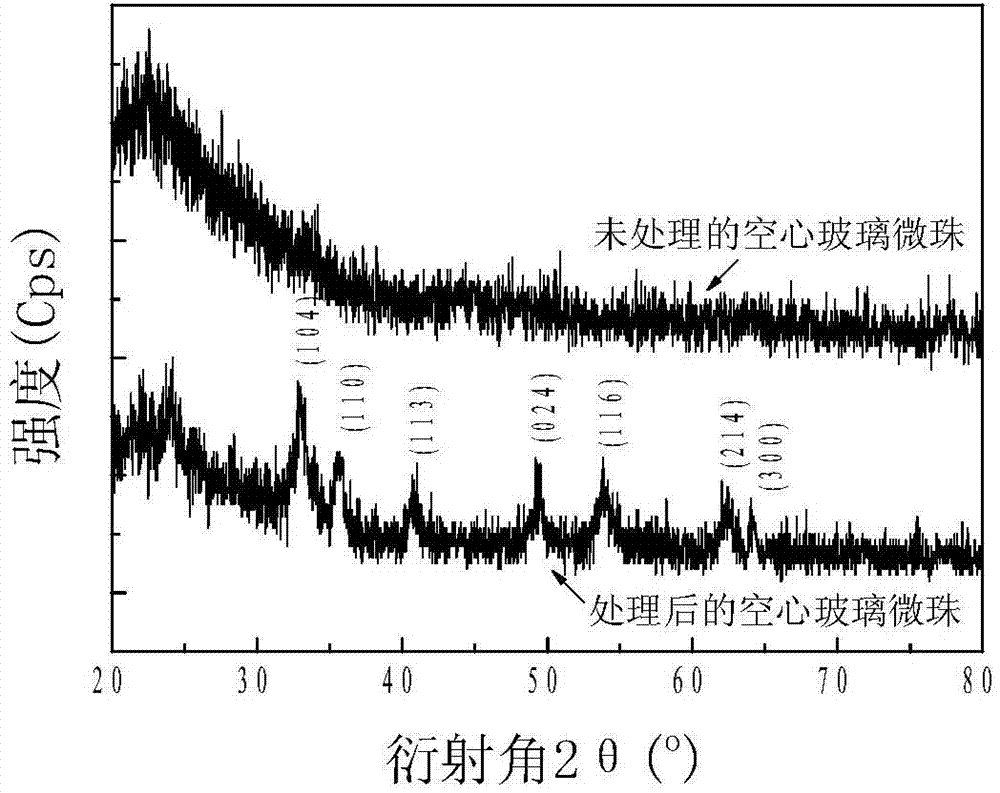

[0083] Weigh 40g of hollow glass microspheres, add the weighed hollow glass microspheres into 1L of tap water, and mechanically stir at a rate of 100rpm at 50°C for 1h, then remove the hollow glass microspheres floating on the surface of the tap water out, and then carry out dehydration treatment to obtain hollow glass microspheres after flotation; weigh the hollow glass microspheres and sodium hydroxide after flotation respectively according to the mass ratio of 4:1, and add the weighed sodium hydroxide to Prepare a sodium hydroxide solution with a mass-volume concentration of 10g / L in deionized water; add the hollow glass beads after flotation to a mass-volume concentration of 10g / L sodium hydroxide solution at 60°C, Mechanically stir the hollow glass microspheres immersed in the sodium hydroxide solution for 35 minutes. After the hollow glass microspheres are taken out from the sodium hydroxide solution, the hollow glass microspheres are repeatedly washed with deionized wate...

Embodiment 2

[0089] Weigh 80g of hollow glass microspheres, add the weighed hollow glass microspheres into 1L tap water, and mechanically stir at a rate of 200rpm at 70°C for 1h, then remove the hollow glass microspheres floating on the surface of tap water out, and then carry out dehydration treatment to obtain hollow glass microspheres after flotation; weigh the hollow glass microspheres and sodium hydroxide after flotation respectively according to the mass ratio of 4:1, and add the weighed sodium hydroxide to Prepare a sodium hydroxide solution with a mass-volume concentration of 20g / L in deionized water; add the hollow glass microspheres after flotation to a mass-volume concentration of 20g / L sodium hydroxide solution at 90°C, Mechanically stir the hollow glass microspheres immersed in the sodium hydroxide solution for 25 minutes. After the hollow glass microspheres are taken out from the sodium hydroxide solution, the hollow glass microspheres are repeatedly washed with deionized wate...

Embodiment 3

[0095] Weigh 60g of hollow glass microspheres, add the weighed hollow glass microspheres into 1L of tap water, and mechanically stir at a rate of 150rpm at 60°C for 1h, then remove the hollow glass microspheres floating on the surface of the tap water out, and then carry out dehydration treatment to obtain hollow glass microspheres after flotation; respectively weigh the washed hollow glass microspheres and sodium hydroxide according to the mass ratio of 4:1, and add the weighed sodium hydroxide to the Prepare a sodium hydroxide solution with a mass-volume concentration of 15g / L in ionized water; add the hollow glass microspheres after flotation to the sodium hydroxide solution with a mass-volume concentration of 15g / L, and mechanically Stir the hollow glass microspheres soaked in the sodium hydroxide solution for 30 minutes. After the hollow glass microspheres are taken out from the sodium hydroxide solution, the hollow glass microspheres are repeatedly washed with deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com