Shifted Al-plating paint for offset printing, preparation method and application thereof

A technology of coating and aluminum plating, applied in the direction of coating, etc., can solve the problem that coating cannot be directly used for offset printing, and achieve the effects of sustainable development, excellent peeling performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of preparation method of the transfer aluminized coating that is suitable for offset printing, the method comprises the following process steps:

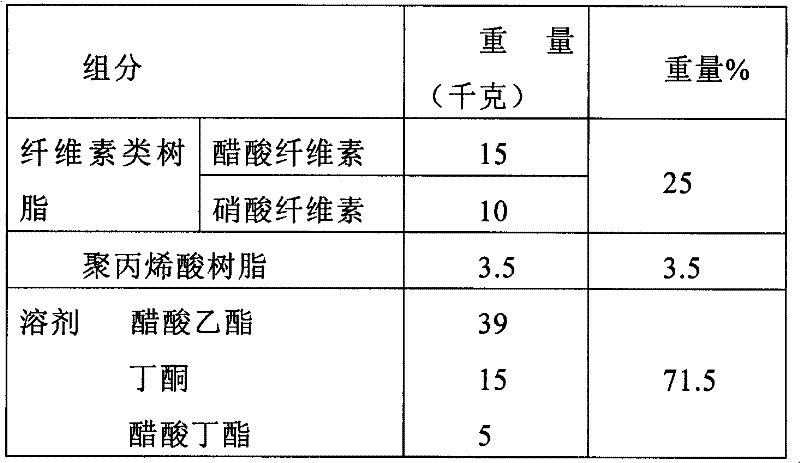

[0056] (1) Prepare raw materials according to the following components and parts by weight:

[0057]

[0058]

[0059] The cellulose resin includes cellulose acetate resin with a molecular weight of 85,000, nitrocellulose resin with a viscosity of 1 / 8S, and the acrylic resin is polybutylacrylate with a molecular weight of 110,000;

[0060] (2) Put the solvent in the reaction kettle according to the recipe, start stirring and heat to 40°C, and mix well;

[0061] (3) Put the resin component into the reaction kettle, and stir at a high speed for 1-5h to completely dissolve the resin component;

[0062] (4) Filtrate after natural cooling to obtain the transfer aluminized coating.

Embodiment 2

[0064] A kind of preparation method of the transfer aluminized coating that is suitable for offset printing, the method comprises the following process steps:

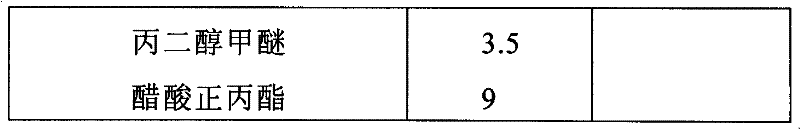

[0065] (1) Prepare raw materials according to the following components and parts by weight:

[0066]

[0067] The cellulose resin is cellulose acetate resin with a molecular weight of 150,000; the acrylic resin is polymethylacrylate-ethyl ester with a molecular weight of 40,000; the vinyl acetate resin is a ternary vinyl acetate resin with a molecular weight of 60,000.

[0068] (2) Put the solvent in the reaction kettle according to the recipe, start stirring and heat to 60°C, and mix well;

[0069] (3) Put the resin component into the reaction kettle, and stir at a high speed for 1-5h to completely dissolve the resin component;

[0070] (4) Filtrate after natural cooling to obtain the transfer aluminized coating.

Embodiment 3

[0072] A kind of preparation method of the transfer aluminized coating that is suitable for offset printing, the method comprises the following process steps:

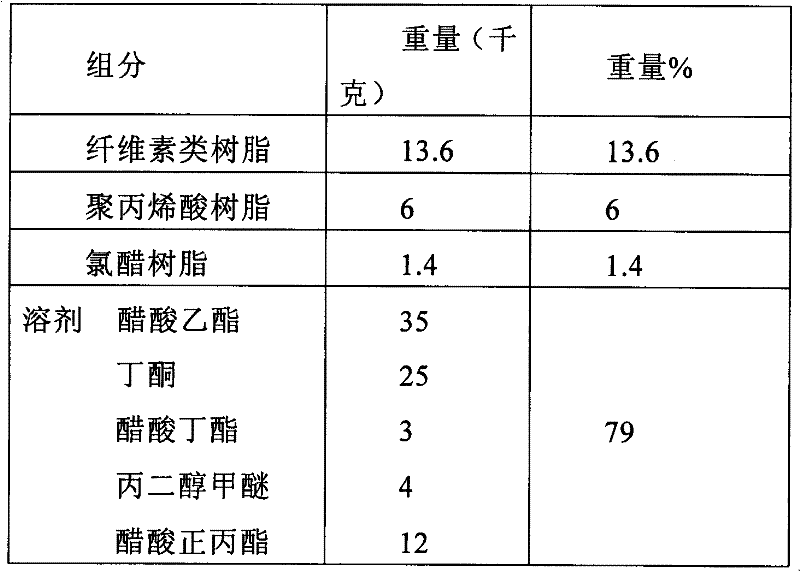

[0073] (1) Prepare raw materials according to the following components and parts by weight:

[0074]

[0075] The cellulose resin is butyl acetate cellulose resin with a molecular weight of 45,000; the acrylic resin is polymethyl methacrylate-butyl methacrylate with a molecular weight of 170,000;

[0076] (2) Put the solvent in the reaction kettle according to the recipe, start stirring and heat to 60°C, and mix well;

[0077] (3) Put the resin component into the reaction kettle, and stir at a high speed for 1-5h to completely dissolve the resin component;

[0078] (4) Filtrate after natural cooling to obtain the transfer aluminized coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com